The Science Behind Metal Carved Board Durability

Material Composition and Manufacturing Process

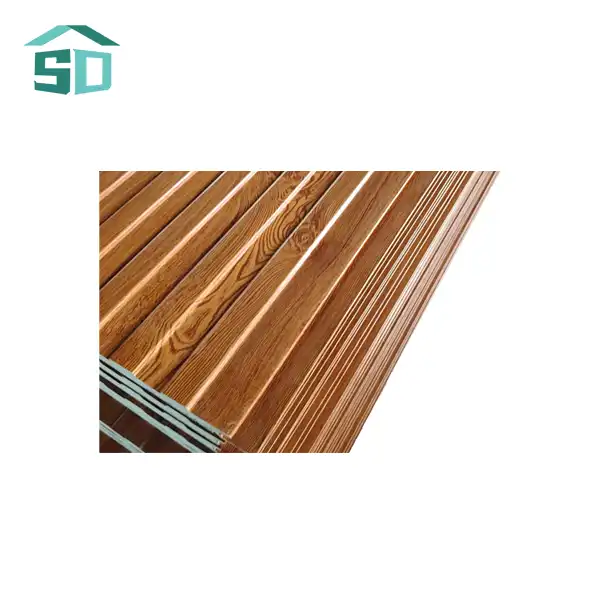

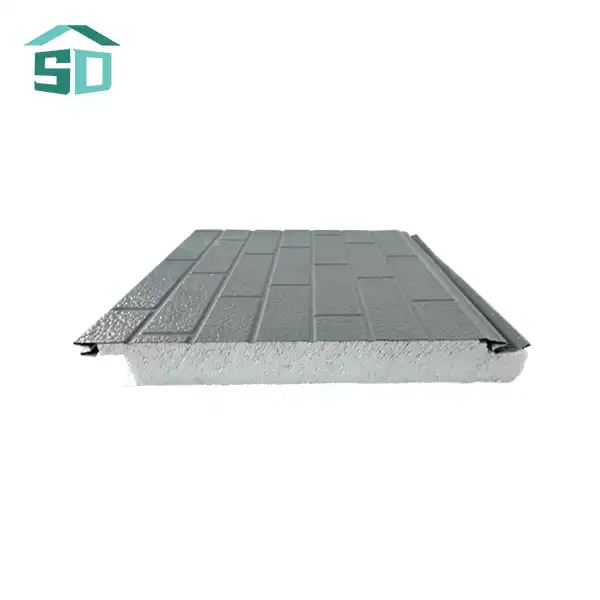

The durability of metal carved boards begins with their core material. High-grade steel or aluminum serves as the foundation, providing inherent strength and resistance to wear. These metals undergo rigorous quality control processes, ensuring only the finest materials make it to production. The manufacturing process involves advanced techniques such as precision cutting, shaping, and carving, which contribute to the structural integrity of the final product.

During production, the metal is subjected to various treatments that enhance its durability. These may include heat treatments to improve hardness and strength, as well as the application of protective coatings. The surface treatment is particularly crucial, as it forms a barrier against environmental factors that could potentially degrade the metal over time.

Protective Coatings and Surface Treatments

A key factor in the longevity of metal carved boards is the application of specialized coatings. These coatings serve multiple purposes:

- Corrosion Resistance: A waterproof rate of 0.0008 ensures excellent protection against moisture and rust.

- UV Protection: Shields the metal from sun damage, preventing fading and degradation.

- Scratch Resistance: Adds an extra layer of durability to the surface, maintaining the board's appearance.

- Chemical Resistance: Protects against various environmental pollutants and chemicals.

The thickness of surface materials, ranging from 0.23mm to 0.27mm, provides an additional layer of protection without compromising the intricate designs of the carved boards.Structural Design and Engineering

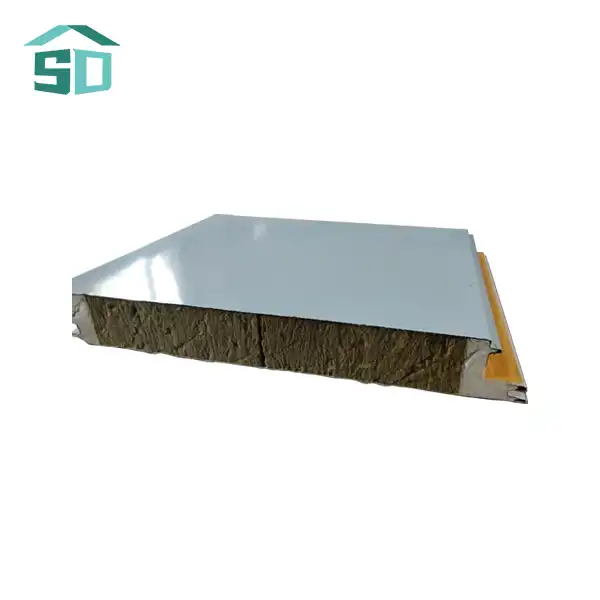

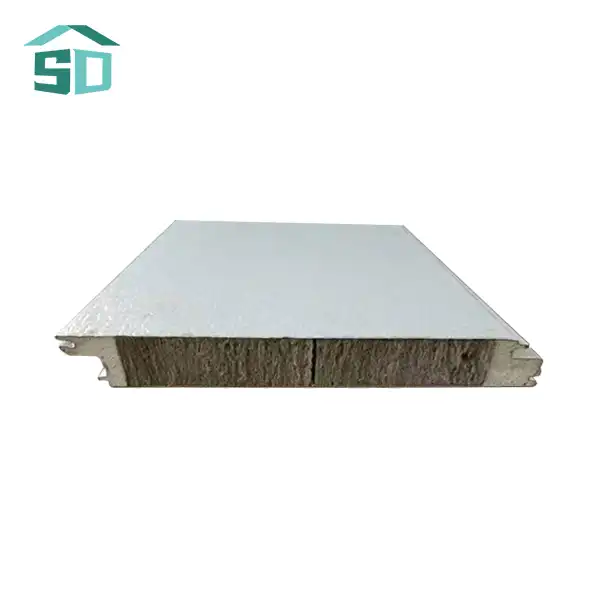

The durability of metal carved boards is not just about the material; it's also about intelligent design. Engineers carefully consider factors such as:

- Load Distribution: Ensuring the board can evenly distribute weight and stress.

- Thermal Expansion: Accounting for temperature fluctuations to prevent warping or buckling.

- Joint and Connection Design: Creating secure attachments that maintain integrity over time.

With a thermal conductivity of 0.018W/m.k and thermal resistance of 2.09m2k/w, these boards are engineered to withstand temperature variations without compromising their structure or appearance.Environmental Resilience of Metal Carved Boards

Weather Resistance and Durability

Metal carved boards exhibit exceptional resilience against various weather conditions. Their robust construction allows them to withstand:

- Extreme Temperatures: From scorching heat to freezing cold, without warping or cracking.

- Heavy Rainfall: The low waterproof rate ensures minimal water absorption and prevents rust.

- High Winds: With a wind resistance of 8.0 Kpa, these boards can endure strong gusts without damage.

- Snow and Ice: The surface treatment prevents moisture penetration, reducing the risk of frost damage.

This weather resistance makes metal carved boards an excellent choice for exterior applications, maintaining their appearance and structural integrity year after year.Fire Safety and Heat Resistance

Safety is a paramount concern in building materials, and metal carved boards excel in this aspect. With a fire-protection rating of B1/B2, these boards offer significant resistance to fire spread. This rating indicates:

- Low Flammability: The boards are difficult to ignite.

- Slow Fire Spread: In the event of a fire, the spread is significantly slowed.

- Minimal Smoke Production: Reducing the risk of smoke inhalation during emergencies.

The inherent properties of metal, combined with fire-resistant coatings, contribute to the overall fire safety of structures incorporating these boards.Resistance to Pests and Biological Factors

Unlike organic materials, metal carved boards are impervious to many biological threats:

- Insect Resistance: Termites and other wood-boring insects cannot damage metal.

- Mold and Mildew Resistance: The non-porous nature of metal prevents the growth of fungi.

- Rot Resistance: Metal does not decompose like wood, ensuring long-term structural integrity.

This resistance to biological factors significantly reduces maintenance needs and extends the lifespan of the boards.Longevity and Maintenance of Metal Carved Boards

Expected Lifespan and Durability Factors

The lifespan of metal carved boards is impressive, often exceeding several decades with proper care. Factors contributing to this longevity include:

- Material Quality: High-grade metals ensure a strong foundation for durability.

- Manufacturing Precision: Careful craftsmanship reduces weak points and potential failure areas.

- Protective Treatments: Advanced coatings extend the life of the boards by protecting against environmental factors.

- Installation Quality: Proper installation techniques ensure the boards perform optimally over time.

With these factors in place, metal carved boards can maintain their structural integrity and aesthetic appeal for 30 years or more, depending on the specific environmental conditions and maintenance practices.Maintenance Requirements and Best Practices

While metal carved boards are low-maintenance, some care is required to ensure their longevity:

- Regular Cleaning: Gentle washing with mild soap and water removes dirt and pollutants.

- Inspection: Periodic checks for any signs of damage or wear, especially after extreme weather events.

- Touch-ups: Addressing any scratches or chips in the protective coating promptly.

- Recoating: Applying a new protective coating every few years can refresh and extend the life of the boards.

These simple maintenance practices can significantly extend the life and preserve the appearance of metal carved boards.Cost-Effectiveness Over Time

While the initial investment in metal carved boards may be higher than some alternatives, their long-term cost-effectiveness is noteworthy:

- Reduced Replacement Frequency: The long lifespan means less frequent replacements.

- Lower Maintenance Costs: Minimal upkeep requirements translate to savings over time.

- Energy Efficiency: The insulating properties (thermal resistance of 2.09m2k/w) can contribute to energy savings in buildings.

- Increased Property Value: The aesthetic appeal and durability can enhance overall property value.

When considering the total cost of ownership over decades, metal carved boards often prove to be a wise investment.Conclusion

Metal carved boards stand out as a paragon of durability in the world of architectural and decorative materials. Their resilience stems from a combination of high-quality materials, advanced manufacturing processes, and intelligent design. From weather resistance to fire safety, these boards offer a comprehensive solution for both aesthetic and functional needs in various applications. The longevity of metal carved boards, coupled with their low maintenance requirements, makes them a cost-effective choice in the long run. As we've explored, the science behind their durability is as impressive as their visual appeal, making them a superior choice for those seeking lasting beauty and functionality in their projects.

Ready to transform your space with the enduring elegance of metal carved boards? At Weifang Sandong Building Materials Co., Ltd., we're committed to providing top-quality exterior cladding and facade solutions that stand the test of time. Our metal carved boards offer unparalleled durability, customizable designs, and exceptional performance. Whether you're working on a residential, commercial, or industrial project, our expert team is here to help you find the perfect solution. Contact us today at info@sdqsc.com to learn more about how our metal carved boards can elevate your next project to new heights of durability and style.

References

1.American Society for Testing and Materials. (2021). "Standard Test Methods for Fire Tests of Building Construction and Materials." ASTM E119-20.

2.National Association of Corrosion Engineers. (2020). "Corrosion Control in the Aerospace Industry." NACE International.

3.U.S. Department of Energy. (2022). "Energy Efficiency in Commercial Buildings." Office of Energy Efficiency & Renewable Energy.

4.American Institute of Architects. (2021). "Architectural Metals: Selection and Specification." AIA Knowledge Net.

5.International Code Council. (2021). "International Building Code." ICC Digital Codes.