Understanding PU and Fibreglass Sandwich Panels

Composition and Manufacturing Process

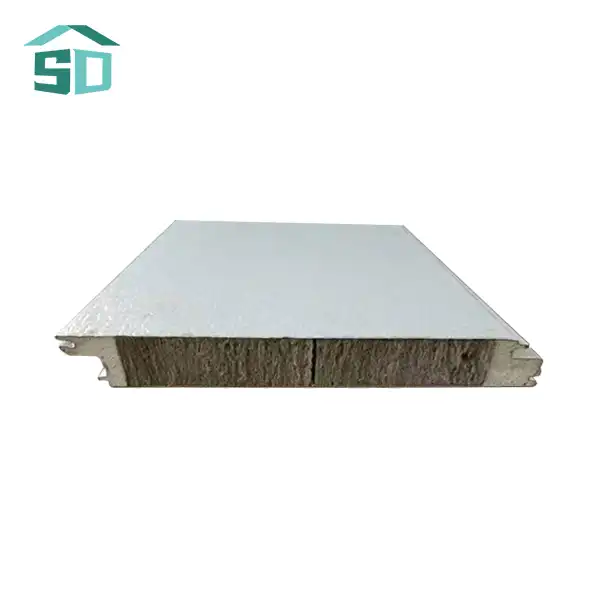

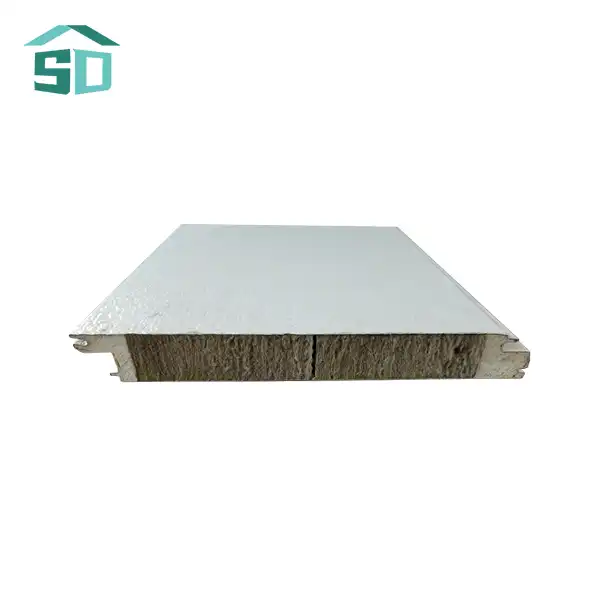

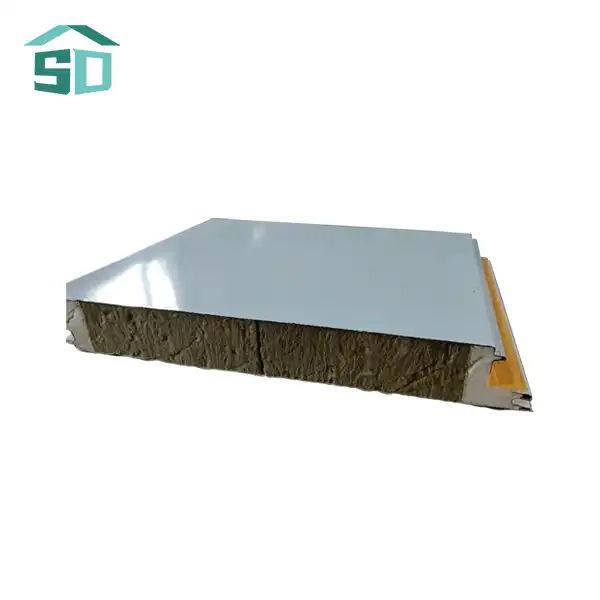

PU sandwich panels consist of a polyurethane foam core sandwiched between two metal facings, typically steel or aluminum. The manufacturing process involves injecting liquid polyurethane between the metal sheets, which then expands and hardens to form a rigid foam core. This process creates a strong bond between the core and facings, resulting in a lightweight yet sturdy panel.

Fibreglass sandwich panels, in contrast, feature a core material (often foam or honeycomb) encased between layers of fibreglass-reinforced polymer (FRP) skins. The production process involves laying up alternating layers of fibreglass mat and resin, which are then cured under pressure and heat. This method creates a strong, durable panel with excellent strength-to-weight characteristics.

Key Properties and Characteristics

PU insulated sandwich panels are renowned for their exceptional thermal insulation properties. The closed-cell structure of polyurethane foam provides superior R-value per inch compared to many other insulation materials. These panels also offer good fire resistance when treated with flame retardants and can be easily customized in terms of thickness and facing materials.

Fibreglass sandwich panels, while also providing insulation, stand out for their remarkable strength and durability. The fibreglass skins offer excellent resistance to corrosion, UV radiation, and chemical exposure. These panels maintain their structural integrity even in harsh environments, making them a go-to choice for demanding applications.

Comparative Analysis: PU vs. Fibreglass Sandwich Panels

Thermal Performance

In terms of thermal insulation, PU sandwich panels have a clear advantage. The closed-cell structure of polyurethane foam provides superior thermal resistance, typically offering R-values of 6-7 per inch of thickness. This exceptional insulation capacity makes PU panels an excellent choice for applications where temperature control is crucial, such as cold storage facilities or energy-efficient buildings.

Fibreglass sandwich panels, while still providing insulation, generally have lower R-values compared to PU panels of the same thickness. However, the thermal performance of fibreglass panels can be enhanced by using specialized core materials or increasing panel thickness.

Structural Strength and Durability

When it comes to strength-to-weight ratio, fibreglass sandwich panels often outperform their PU counterparts. The fibreglass skins provide excellent tensile and flexural strength, allowing these panels to withstand significant loads without deformation. This characteristic makes them ideal for applications in the marine and aerospace industries, where weight savings and structural integrity are paramount.

PU sandwich panels, while not as strong as fibreglass, still offer good structural performance for many applications. The bond between the foam core and metal facings provides rigidity and load-bearing capacity suitable for most building envelope applications.

Environmental Resistance

Fibreglass sandwich panels exhibit superior resistance to environmental factors such as UV radiation, moisture, and chemical exposure. The inert nature of fibreglass makes these panels highly resistant to corrosion, even in marine environments. This durability translates to longer service life and reduced maintenance requirements.

PU insulated sandwich panels, particularly those with metal facings, can be susceptible to corrosion in harsh environments. However, proper selection of facing materials (such as aluminum or stainless steel) and protective coatings can significantly enhance their environmental resistance.

Cost Considerations

Generally, PU sandwich panels tend to be more cost-effective than fibreglass panels, especially for large-scale applications like building envelopes. The manufacturing process for PU panels is often more streamlined, allowing for faster production and lower material costs.

Fibreglass sandwich panels, due to their more complex manufacturing process and specialized materials, typically come at a higher price point. However, their superior durability and performance in specific applications can justify the additional cost over the long term.

Best Uses and Applications

PU Sandwich Panels: Ideal Scenarios

PU sandwich panels excel in applications where thermal insulation is a primary concern. Some of the best uses for these panels include:

- Cold storage facilities and refrigerated warehouses

- Building envelopes for energy-efficient structures

- Roofing systems for commercial and industrial buildings

- Partition walls in temperature-controlled environments

- Prefabricated modular buildings

The lightweight nature of PU insulated sandwich panels also makes them suitable for renovation projects where minimizing additional structural load is crucial.

Fibreglass Sandwich Panels: Optimal Applications

The unique properties of fibreglass sandwich panels make them ideal for specialized applications, including:

- Marine vessel construction (hulls, decks, and superstructures)

- Aerospace components (aircraft interiors, radomes)

- Transportation industry (truck bodies, train interiors)

- Corrosive industrial environments

- Architectural facades requiring high durability and aesthetic appeal

The excellent strength-to-weight ratio of fibreglass panels makes them particularly valuable in applications where weight savings translate to improved performance or energy efficiency.

Hybrid Solutions and Emerging Trends

As technology advances, we're seeing the emergence of hybrid sandwich panels that combine the benefits of both PU and fibreglass. These innovative solutions aim to offer the thermal efficiency of PU cores with the strength and durability of fibreglass skins. Such hybrid panels are finding applications in high-performance building envelopes and specialized industrial settings.

Another trend is the development of bio-based and recycled materials for sandwich panel cores and facings. These sustainable alternatives aim to reduce the environmental impact of construction materials while maintaining performance standards.

Conclusion

The choice between PU and fibreglass sandwich panels ultimately depends on the specific requirements of each project. PU insulated sandwich panels offer superior thermal insulation and cost-effectiveness, making them ideal for building envelopes and temperature-controlled environments. Fibreglass panels, with their exceptional strength and durability, excel in demanding applications such as marine and aerospace industries. By carefully considering factors like thermal performance, structural requirements, environmental exposure, and budget constraints, architects and builders can select the most appropriate sandwich panel solution for their needs.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of choosing the right materials for your construction projects. Our extensive range of high-quality sandwich panels, including both PU and fibreglass options, caters to diverse applications across various industries. We're committed to providing innovative and efficient insulation solutions that meet the highest standards of performance and sustainability. For expert advice on selecting the perfect sandwich panels for your next project, don't hesitate to reach out to our team at info@sdqsc.com.

FAQ

What are the main differences between PU and fibreglass sandwich panels?

PU panels excel in thermal insulation and are more cost-effective, while fibreglass panels offer superior strength-to-weight ratios and better environmental resistance.

Which type of panel is best for cold storage facilities?

PU sandwich panels are typically the preferred choice for cold storage due to their excellent thermal insulation properties.

Are fibreglass sandwich panels suitable for marine applications?

Yes, fibreglass panels are ideal for marine use due to their corrosion resistance and high strength-to-weight ratio.

References

1.Davies, J. M. (2001). Lightweight sandwich construction. John Wiley & Sons.

2.Ashby, M. F., & Bréchet, Y. J. M. (2003). Designing hybrid materials. Acta materialia, 51(19), 5801-5821.

3.Correia, J. R., Garrido, M., Gonilha, J. A., Branco, F. A., & Reis, L. G. (2012). GFRP sandwich panels with PU foam and PP honeycomb cores for civil engineering structural applications. International Journal of Structural Integrity.

4.Alam, P., & Rastogi, D. (2019). Sandwich Panels: Materials, Construction and Applications. Springer.