The Innovative Structure and Composition of Aluminum Foam Sandwich Panels

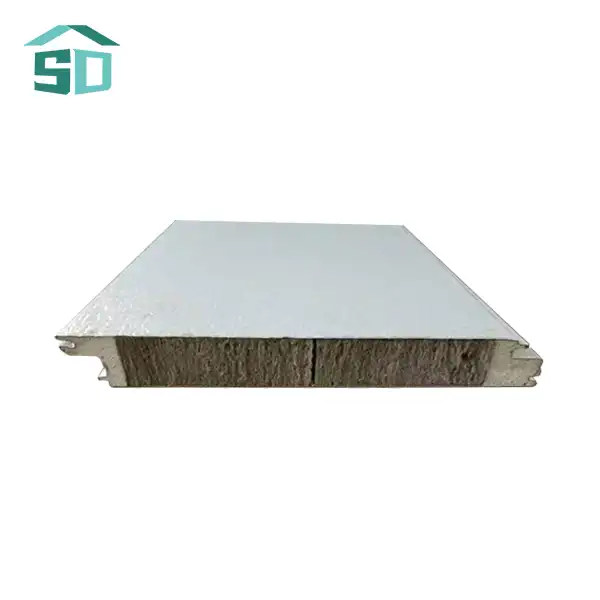

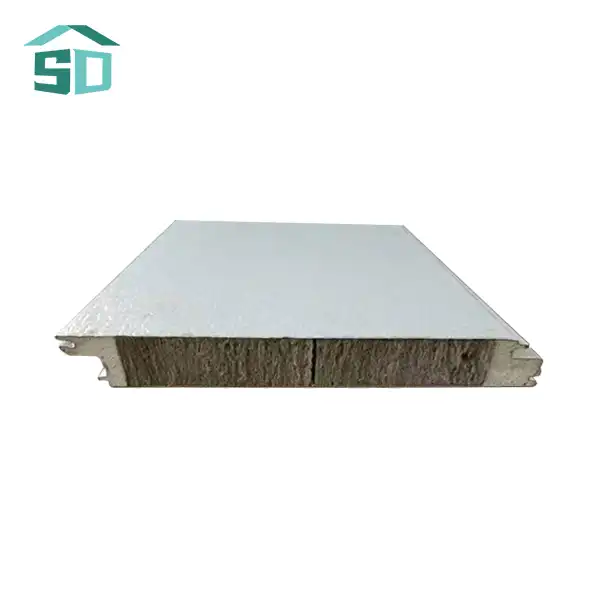

Core Technology: Lightweight Aluminum Foam

At the heart of aluminum foam sandwich panels lies a groundbreaking core technology - lightweight aluminum foam. This ingenious material is created through a specialized process that introduces gas bubbles into molten aluminum, resulting in a cellular structure that resembles a sponge. The outcome is a core that boasts remarkable strength-to-weight ratio, providing exceptional structural integrity without adding unnecessary bulk to the panel.

The aluminum foam core is the key to the panel's impressive performance characteristics. Its unique structure allows for superior load distribution, enhancing the overall compressive strength of the panel. With a compressive strength of 52.7 kPa, these panels can withstand significant pressure without compromising their integrity. This makes them ideal for applications where structural stability is paramount, such as in high-rise buildings or areas prone to extreme weather conditions.

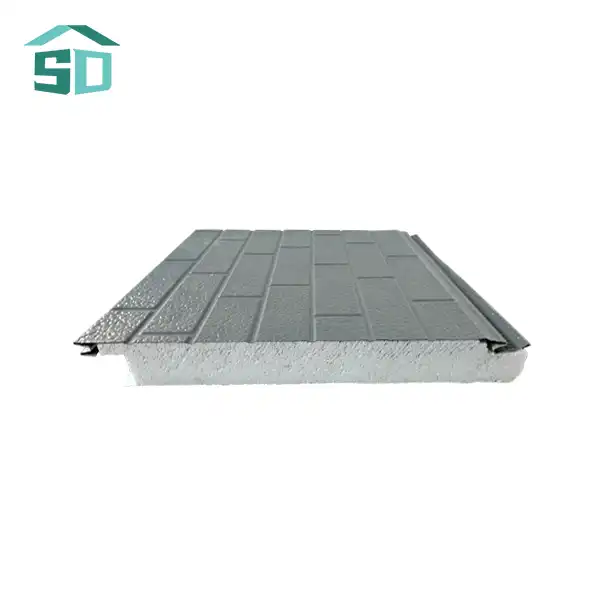

Surface Layers: Thin Yet Robust Aluminum Sheets

Complementing the foam core are the surface layers of the aluminum foam sandwich panel. These thin yet robust aluminum sheets serve as protective skins, encasing the core and providing additional strength and durability to the overall structure. The thickness of these surface materials typically ranges from 0.23mm to 0.27mm, striking an optimal balance between weight and performance.

These surface layers play a crucial role in the panel's weatherproofing capabilities. With a remarkably low waterproof rate of 0.0008, the panels offer excellent protection against moisture ingress, ensuring long-lasting performance even in challenging environmental conditions. Moreover, the aluminum surface layers contribute to the panel's corrosion resistance, maintaining its aesthetic appeal and structural integrity over time.

Customizable Dimensions for Versatile Applications

One of the most advantageous features of aluminum foam sandwich panels is their customizable dimensions. These panels can be tailored to suit various applications, with different thicknesses available for interior and exterior use. Interior panels typically measure 10mm in thickness, while exterior panels come in 16mm or 20mm options to provide enhanced insulation and durability for outdoor environments.

The width of these panels also varies depending on their intended use. Exterior panels generally have a width of 383mm, while interior panels offer a wider option at 450mm. This flexibility in sizing allows architects and builders to optimize panel usage for different wall configurations, minimizing waste and streamlining the installation process.

Performance Characteristics That Set Aluminum Foam Sandwich Panels Apart

Thermal Efficiency: A New Standard in Insulation

One of the standout features of aluminum foam sandwich panels is their exceptional thermal efficiency. With a thermal conductivity of just 0.018 W/m.k and a thermal resistance of 2.09 m²K/W, these panels set a new standard in insulation performance. This remarkable insulating capability translates to significant energy savings for buildings, reducing the load on heating and cooling systems and contributing to lower operational costs.

The superior thermal performance of these panels is attributed to the unique structure of the aluminum foam core. The numerous air pockets within the foam act as barriers to heat transfer, effectively minimizing thermal bridging and maintaining a comfortable indoor environment regardless of external temperature fluctuations.

Fire Resistance: Enhancing Building Safety

Safety is a paramount concern in modern construction, and aluminum foam sandwich panels address this with their impressive fire-resistant properties. These panels boast a fire-protection rating of B1/B2, indicating their ability to withstand fire and limit its spread. This characteristic is crucial in enhancing overall building safety, providing valuable time for evacuation in the event of a fire emergency.

The fire-resistant nature of these panels is not just limited to their core material. The aluminum surface layers also contribute to their fire safety profile, as aluminum does not readily support combustion. This comprehensive approach to fire resistance makes aluminum foam sandwich panels an excellent choice for both residential and commercial buildings where safety is a top priority.

Wind Resistance: Standing Strong Against the Elements

In regions prone to high winds or severe weather conditions, the structural integrity of building materials is of utmost importance. Aluminum foam sandwich panels excel in this aspect, offering impressive wind resistance capabilities. With a wind resistance rating of 8.0 kPa, these panels can withstand significant wind loads without compromising their performance or stability.

This high wind resistance is achieved through the combination of the strong aluminum surface layers and the unique structure of the foam core. The foam's cellular structure allows for efficient load distribution, while the rigid surface layers provide additional strength. This makes aluminum foam sandwich panels an ideal choice for exterior cladding in coastal areas or high-rise buildings where wind forces can be substantial.

Versatility and Aesthetic Appeal: The Finishing Touch

Customizable Design Options

Beyond their impressive technical specifications, aluminum foam sandwich panels offer extensive customization options to suit various architectural visions. The panels can be tailored in terms of color, pattern, and texture, allowing designers to create unique and visually striking facades. This versatility makes them suitable for a wide range of applications, from sleek modern office buildings to warm and inviting residential complexes.

The customization possibilities extend to the finish of the aluminum surface layers. Options may include brushed metal looks, wood grain patterns, or even digitally printed designs. This flexibility enables architects and designers to achieve their desired aesthetic without compromising on the panel's performance characteristics.

Applications Across Various Building Types

The versatility of aluminum foam sandwich panels is further exemplified by their suitability for a wide array of building types. These panels find application in residential complexes, office buildings, villas, and even in the renovation of historic structures. Their lightweight nature makes them ideal for both new construction and retrofit projects, where minimizing additional structural load is crucial.

In municipal buildings and security kiosks, the panels' durability and fire-resistant properties make them a practical choice. For garden structures or outdoor living spaces, their weather-resistant qualities ensure long-lasting performance and aesthetic appeal. This adaptability across various building types underscores the panels' position as a truly versatile building material.

Eco-Friendly Credentials

In an era where sustainability is increasingly important in construction, aluminum foam sandwich panels offer significant eco-friendly benefits. The use of aluminum, a highly recyclable material, in both the core and surface layers contributes to the panels' green credentials. Additionally, their excellent insulation properties lead to reduced energy consumption in buildings, lowering the overall carbon footprint.

The longevity and durability of these panels also play a role in their sustainability profile. By resisting corrosion and maintaining their performance over time, they reduce the need for frequent replacements or repairs, minimizing waste and resource consumption in the long term.

Conclusion

Aluminum foam sandwich panels represent a significant advancement in building material technology, offering a unique combination of strength, insulation, fire resistance, and design flexibility. Their innovative structure, comprising a lightweight aluminum foam core sandwiched between thin aluminum sheets, provides exceptional performance across various metrics, from thermal efficiency to wind resistance.

These panels not only enhance the structural and energy performance of buildings but also offer architects and designers a versatile canvas for creative expression. Their ability to be customized in terms of dimensions, colors, and patterns makes them suitable for a wide range of applications, from modern office complexes to historic building renovations.

As the construction industry continues to evolve towards more sustainable and efficient practices, aluminum foam sandwich panels stand out as a forward-thinking solution. They embody the perfect balance of performance, aesthetics, and environmental consciousness, making them an invaluable asset in modern construction projects.

For more information about our aluminum foam sandwich panels and other exterior cladding and facade solutions, please don't hesitate to contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is ready to assist you in elevating your next construction project with our innovative building materials.