The Composition and Manufacturing of Fiberglass Sandwich Panels

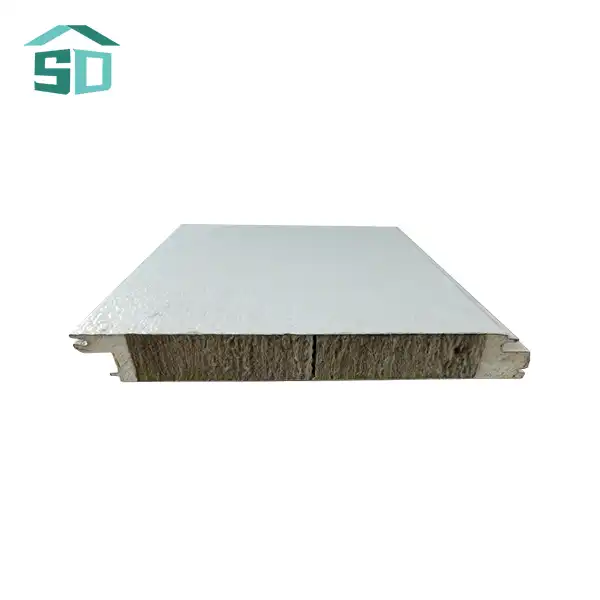

Core Materials: The Heart of Insulation

The core of a fiberglass sandwich panel plays a crucial role in its insulation properties. Manufacturers offer various core materials to suit different needs:

- Polyurethane (PU): Known for its excellent thermal insulation and moisture resistance.

- Polystyrene (EPS): Lightweight and cost-effective, offering good insulation properties.

- Rock Wool: Provides superior fire resistance and sound insulation.

- Glass Wool: Offers a balance of thermal and acoustic insulation.

The choice of core material significantly impacts the panel's thermal conductivity, which ranges from 0.022 to 0.045 W/m·K. This low thermal conductivity ensures that fiberglass sandwich panels are highly effective in maintaining indoor temperatures and reducing energy costs.

Fiberglass Sheets: The Protective Exterior

The outer layers of fiberglass sandwich panels are composed of high-quality fiberglass sheets. These sheets are typically reinforced with resins to enhance their strength and durability. The surface finish can be customized to suit various aesthetic preferences:

- Gelcoat: Provides a smooth, glossy finish that is easy to clean and maintain.

- Smooth: Offers a sleek, modern appearance suitable for contemporary designs.

- Textured: Adds depth and visual interest to the panel's surface.

Manufacturers like Weifang Sandong Building Materials Co., Ltd. offer custom RAL color options for fibreglass sandwich panels, allowing architects and designers to create unique and visually striking facades.

Manufacturing Process: Precision and Quality Control

The production of fiberglass sandwich panels involves a meticulous process that ensures consistent quality and performance. Advanced production lines and rigorous quality control systems are employed to monitor every aspect of the manufacturing process. This includes comprehensive inspections of:

- Raw materials: Steel coils, aluminum foil, and polyurethane components

- Panel thickness: Ensuring uniformity across the entire panel

- Paint film thickness: Guaranteeing proper coating for durability

- Mechanical strength: Testing for load-bearing capacity and structural integrity

- Flame retardancy: Verifying fire resistance properties

- Product appearance: Assessing visual quality and consistency

Key Features and Benefits of Fiberglass Sandwich Panels

Unparalleled Durability and Longevity

Fiberglass sandwich panels are engineered to withstand the test of time. Their robust construction and corrosion-resistant properties make them ideal for use in harsh environments. Unlike traditional building materials, these panels do not rot, warp, or deteriorate when exposed to moisture or extreme weather conditions. This exceptional durability translates to reduced maintenance costs and a longer lifespan for the structure.

Superior Thermal Insulation

One of the most significant advantages of fiberglass sandwich panels is their outstanding thermal insulation capabilities. The combination of the insulating core and the low thermal conductivity of fiberglass creates an effective barrier against heat transfer. This results in:

- Improved energy efficiency in buildings

- Reduced heating and cooling costs

- Enhanced indoor comfort throughout the year

Fire Retardant Properties

Safety is paramount in building design, and fibreglass sandwich panels excel in this aspect. These fibreglass sandwich panels are available in Class A or B fire resistance ratings, depending on the specific requirements of the project. The inherent flame-resistant properties of fiberglass, combined with fire-retardant additives in the core material, help to slow the spread of fire and protect the structural integrity of the building.

Versatility in Design and Application

Fiberglass sandwich panels offer remarkable flexibility in terms of design and application. Their customizable nature allows architects and builders to create unique and visually appealing structures. Key aspects of their versatility include:

- Customizable dimensions: Panels can be manufactured in thicknesses of 50mm, 75mm, 100mm, or custom sizes to suit specific project requirements.

- Long spans: Panels can be produced in lengths of up to 12 meters, reducing the number of joints and simplifying installation.

- Variable widths: Available in widths ranging from 1,200mm to 1,500mm to accommodate different building designs.

- Aesthetic options: Custom RAL colors and various surface finishes allow for seamless integration with any architectural style.

Applications and Industry Impact of Fiberglass Sandwich Panels

Wide-ranging Applications in Construction

The versatility and performance of fiberglass sandwich panels make them suitable for a diverse range of construction projects:

- Residential complexes: Providing energy-efficient and aesthetically pleasing exteriors

- Office buildings: Creating modern, low-maintenance facades

- Villas and luxury homes: Offering customizable designs and superior insulation

- Gardens and outdoor structures: Withstanding the elements while enhancing outdoor spaces

- Historic building renovations: Blending modern performance with traditional aesthetics

- Municipal buildings: Ensuring durability and energy efficiency in public structures

- Security kiosks: Providing robust and insulated structures for various security applications

Environmental Impact and Sustainability

As the construction industry increasingly focuses on sustainability, fibreglass sandwich panels emerge as an eco-conscious choice. Their contributions to green building practices include:

- Energy efficiency: Superior insulation properties reduce the carbon footprint of buildings

- Longevity: Durable construction minimizes the need for replacements and repairs

- Recyclability: Many components of fiberglass sandwich panels can be recycled at the end of their life cycle

- Lightweight design: Reduces transportation costs and energy consumption during installation

Cost-Effectiveness and Long-Term Value

While the initial cost of fiberglass sandwich panels may be higher than some traditional building materials, their long-term value proposition is compelling. Factors contributing to their cost-effectiveness include:

- Reduced energy costs due to superior insulation

- Minimal maintenance requirements

- Extended lifespan of the building envelope

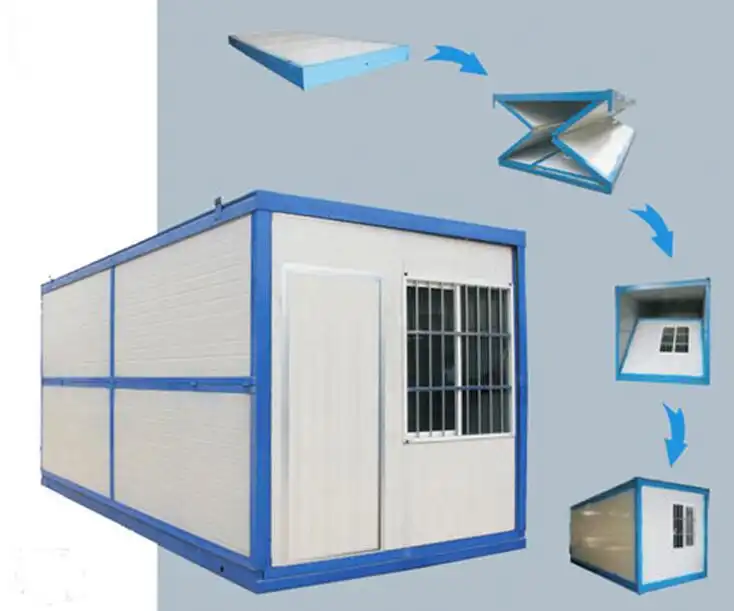

- Faster installation times, reducing labor costs

- Potential for prefabrication, streamlining the construction process

Conclusion

Fibreglass sandwich panels represent a significant advancement in building technology, offering a unique combination of strength, insulation, and versatility. Their wide-ranging applications and numerous benefits make fibreglass sandwich panels an increasingly popular choice for modern construction projects.

As the industry continues to evolve, these innovative fibreglass sandwich panels are poised to play a crucial role in shaping the future of sustainable and efficient building design. For more information about fiberglass sandwich panels and other exterior cladding and facade solutions, please contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com.