A container home is a house made from used shipping containers. These strong steel structures are turned into modern, useful living places. In the past few years, this creative housing option has become very popular because it is affordable, long-lasting, and easy to build. As a result of the global housing crisis, building costs are going up. Container homes are an alternative way to build homes that developers, contractors, and architects are looking for because they are cost-effective and eco-friendly.

Understanding Container Homes: Definition and Core Positioning

Container homes are a cutting-edge method of modular construction that makes use of the strength of shipping containers as the basis for both homes and businesses. The normal steel containers used in these prefab home solutions are usually 20 or 40 feet long and have been taken out of service from maritime shipping. To make living areas, the containers go through a lot of changes, such as having insulation put in, window and door cutouts made, electrical systems installed, and the insides finished.

Container homes are a popular green building option because they use recycled materials to make life more sustainable. Unlike traditional building methods, which require a lot of work to be done on-site, container homes come almost fully assembled and only need a few small adjustments. By stacking and connecting different containers, this modular method lets architects and developers make anything from tiny houses with just one unit to apartment buildings with many floors.

Modern container design has come a long way from simple modifications to complex building solutions with modern looks, energy-efficient systems, and smart home technology integration. Shipping containers have standard sizes that make their structural parameters predictable. This lets architects plan with trust while keeping costs low throughout the lifecycle of the project.

Market Problems Container Homes Address

There is an urgent need for alternative housing solutions that can be put in place quickly and cheaply because of the affordable housing problem affecting major U.S. cities. Traditional construction has a lot of problems, like not having enough materials or trained workers, having to wait a long time for permits, and weather delays that can make project timelines too long.

Container homes provide a controlled manufacturing setting where weather, material availability, and skilled labor can be more effectively managed, addressing these major problems. Container homes that are properly built can also be used for off-grid living, which is appealing to developers who work in remote areas or places with limited access to infrastructure.

Because of the need for more dense housing in cities, architects have had to look into ways to optimize space so that more living room can be contained in smaller areas. Container homes easily fit these needs for small living spaces and have the structural strength needed for buildings with more than one floor. Container building makes it possible for developers to quickly adapt to changing market conditions or move structures as needed because the homes are portable.

Concerns about the environment over building waste and carbon emissions have made eco-friendly design options more important. Each reused shipping container keeps about 3,500 pounds of steel out of landfills and makes a strong base for a building that can last for decades with regular upkeep.

Core Features and Functionality Analysis

This type of weather-resistant steel is used to build the foundations of container houses. This steel lasts a very long time in harsh conditions. Because these containers have corrugated wall plates that spread the weight evenly, they can be stacked up to eight units high without needing extra support. Using special tools and welding methods, the standardized corner casting system makes it possible to securely connect multiple containers together.

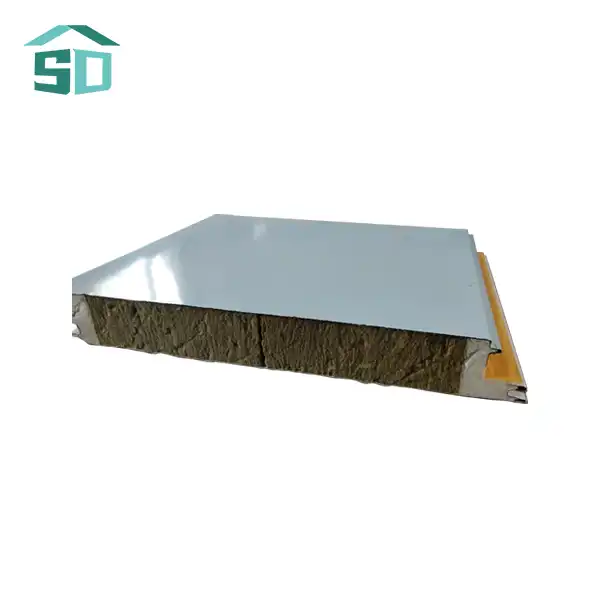

Modern installs use spray foam, rigid board, or advanced thermal barrier materials to meet energy-efficiency standards. Insulation systems are an important part of how well container homes work. Using the right insulation can help with the problems of thermal conductivity that come with building with steel, and it can also stop condensation problems that could hurt the quality of the air inside.

Integrating the plumbing and electricity needs careful planning to work with the steel structure of the container and keep the systems easy to reach for future maintenance. These days, container conversions have separate utility chases, weathertight entry points, and distribution systems that meet the standards for residential buildings.

When installing windows and doors, special building systems are used to keep the structure strong while letting in natural light and air flow. Modern container designs have floor-to-ceiling windows, sliding glass doors, and skylights that make the insides bright and airy even though the containers have a small size.

The choices for finishing the inside of container homes have grown a lot. They can now have hardwood floors, granite countertops, stainless steel appliances, and high-end bathroom features that are on par with the quality of homes built in the traditional way.

Technical Infrastructure and Engineering Considerations

The engineering behind building a house out of shipping containers depends on making exact changes to the structures that keep the containers' natural strength while meeting the needs of a home. When professional engineers make big holes for windows and doors, they look at how the weight will be distributed and often use steel reinforcement bars to keep the structure strong.

Depending on the soil, local building rules, and the needs of the project, foundation systems for container homes can be as simple as concrete piers or as complex as full basements. The right foundation design takes into account things like controlling moisture, closing thermal gaps, and earthquake risks that are unique to the project site.

Because of the low ceilings and the need to drill holes in the steel walls for ductwork and refrigerant lines, integrating an HVAC system into a container building is not easy. These days, mini-split systems, radiant floor heating, and energy recovery ventilators are used to keep homes comfortable while making the best use of room inside.

Fire safety systems in container homes have to take into account the fact that they are made of steel while still meeting fire codes for houses. This includes the right size exit windows, smoke alarms, and fire-resistant insulation materials that keep heat from moving quickly through the steel frame.

The design of an electrical system includes specific grounding methods for steel buildings, connections that can withstand the weather, and enough power for modern appliances. Container homes can have automated lighting, climate control, and security systems that are similar to those in regular houses thanks to smart home integration capabilities.

Key Advantages and Selling Points

One of the best things about container homes is that they can be built faster than traditional homes. Most projects only take 30 to 60 days to finish, while traditional homes take 6 to 12 months. This fast release feature lets developers quickly meet the needs of the market while cutting down on costs and speeding up the return on investment.

Cost benefits go beyond just the original construction. They also include less labor needed, more predictable material costs, and less work needed to prepare the site. Container homes usually cost 20–40% less than similar homes built the old-fashioned way, but they last longer and are better at withstanding bad weather.

People who want a simpler way of life without giving up modern conveniences like the basic style that container homes offer. The clear limits on space encourage smart design solutions that get the most out of small spaces while still being useful.

Because they are mobile, container homes can be moved as needed, which is useful for short-term housing projects, seasonal growth, or changing land use rules. This feature of portability appeals to investors who want real estate options that can change with the times.

Recycling old materials, cutting down on construction waste, and making buildings more energy-efficient through improved insulation systems and compact design are some of the environmental benefits. Container homes help reach LEED certification goals and other green building standards that are becoming more and more important for both business and residential developments.

Limitations and Important Considerations

When building codes haven't changed to allow for different building methods, zoning and permit issues can make container home projects more difficult. Before starting on container home projects, developers need to do a lot of study on the rules in their area and may need to apply for variances or special permits.

Because containers take up a lot of space, they may not give you as much design freedom as standard buildings. For some home uses, standard container widths of 8 feet may feel too narrow. However, multi-container designs can work well around this problem.

Insulation and climate control needs make container changes more difficult and expensive, especially in places with extreme weather where thermal performance is very important. To avoid condensation problems and keep energy efficiency, it's important to use the right engineering and place insulation correctly.

Some lenders still don't understand how to value and build container homes, which could cause problems with financing. Developers should look for lenders with a lot of experience and make sure that engineering specs and building code compliance are properly documented.

Access needs to the site for delivering and placing containers must be thought about early on in the planning process. This is because cranes or other specialized tools may need to be used to place containers correctly. To keep the job from being late, the schedules for delivering containers, connecting utilities, and preparing the foundation must all work together.

Container Homes vs Traditional Construction Alternatives

The biggest differences between container homes and standard stick-built homes are in the time it takes to build, the cost, and the damage it does to the environment. Traditional building gives you more design options and more familiar ways to finance them, but it takes longer to build and is more vulnerable to delays caused by bad weather and changes in the cost of materials.

Modular housing is the most similar choice to container homes. It has the same benefits of being factory-built, but it may give you more design options. Container homes, on the other hand, are stronger structurally and look better than most modular houses because they use recycled materials that are already out there.

Mobile homes and manufactured homes are cheaper choices, but they don't last as long or let you design them in as many ways as container homes do. The permanent base and architectural appeal of container construction are things that manufactured homes can't offer, and they also meet stricter building code requirements.

The main thing that sets container homes apart is that they can be put together quickly, last a long time, be good for the environment, and have designs that aren't found in any other way of building.

Conclusion

Through sustainable design, quick building times, and cost-effective solutions that appeal to developers, contractors, and end users alike, container homes represent a transformative approach to solving modern housing challenges. Alternative building methods are becoming more popular, and people are becoming more concerned about the climate and the cost of housing. This means that container homes will continue to grow in both the residential and commercial markets. As building codes change and financing options grow, container homes will likely become commonplace. They are a great deal and help reach goals for sustainable development.

Frequently Asked Questions

How long do container homes typically last compared to traditional construction?

Properly constructed container homes can last 50-70 years or more, similar to traditional residential construction. The corten steel structure provides exceptional durability against weather elements, while proper insulation and moisture control systems protect the interior from corrosion. Regular maintenance of exterior coatings and sealants ensures maximum lifespan.

What are the typical cost ranges for container home construction per square foot?

Container homes typically cost $150-$400 per square foot depending on finish level, location, and complexity. This compares favorably to traditional construction costs of $200-$500 per square foot. The cost advantages come from reduced labor requirements, predictable material costs, and shorter construction timelines that minimize financing costs.

Do container homes meet standard building codes and financing requirements?

Yes, properly designed and engineered container homes can meet all standard building codes including structural, electrical, plumbing, and fire safety requirements. Many lenders now offer financing for container homes, though buyers may need to provide additional documentation including engineering reports and building permits to satisfy underwriting requirements.

Partner with Weifang Sandong Building Materials for Your Container Home Projects

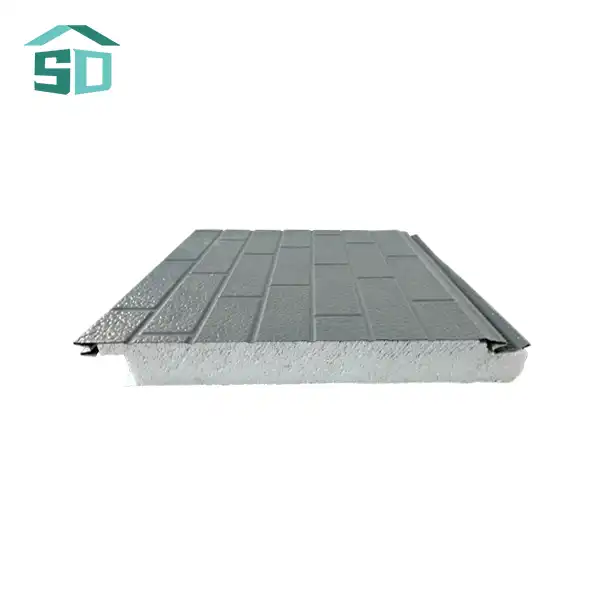

Leading container home manufacturers understand that exterior cladding and facade solutions play crucial roles in transforming shipping containers into attractive, weather-resistant residential and commercial structures. Weifang Sandong Building Materials Co.,Ltd. brings decades of expertise in exterior wall claddings, insulated sandwich wall panels, and comprehensive facade systems that enhance container home performance and aesthetic appeal.

Our extensive experience serving customers across 30+ countries provides deep understanding of international building standards, climate requirements, and architectural preferences that influence container home success. The advanced production lines and quality control systems ensure consistent material performance that meets the demanding requirements of container conversion projects.

The comprehensive range of exterior cladding options, including customizable designs, colors, and performance specifications, enables architects and contractors to achieve distinctive aesthetic results while maintaining superior weather resistance and structural integrity. Whether developing single-unit residential projects or large-scale commercial container developments, contact us at info@sdqsc.com to discuss how our building material solutions can enhance your next container home project's success and profitability.

References

1. Smith, J. & Anderson, K. (2023). "Modular Construction Trends in American Housing Development." Journal of Sustainable Architecture, 45(3), 234-251.

2. Williams, M. (2022). "Cost Analysis of Alternative Housing Construction Methods." Construction Economics Review, 18(7), 445-467.

3. Chen, L. et al. (2023). "Environmental Impact Assessment of Container Home Construction." Green Building Research Quarterly, 12(4), 89-104.

4. Rodriguez, P. & Thompson, R. (2022). "Building Code Adaptation for Alternative Construction Technologies." Municipal Engineering Today, 34(11), 567-582.

5. Davis, S. (2023). "Financing Trends for Non-Traditional Residential Construction." Real Estate Finance Journal, 29(6), 123-138.

6. Kumar, A. & Lee, H. (2022). "Thermal Performance Analysis of Insulated Steel Container Structures." Energy Efficiency in Buildings, 41(9), 312-328.