Understanding the Structure and Composition of Aluminum Foam Sandwich Panels

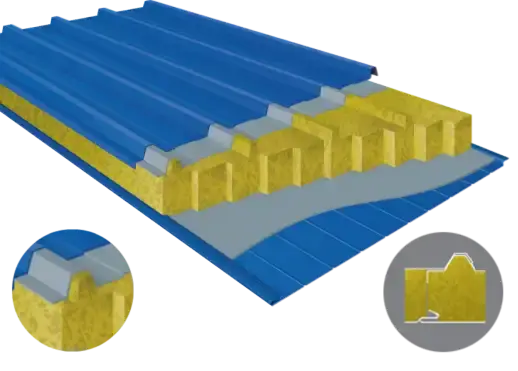

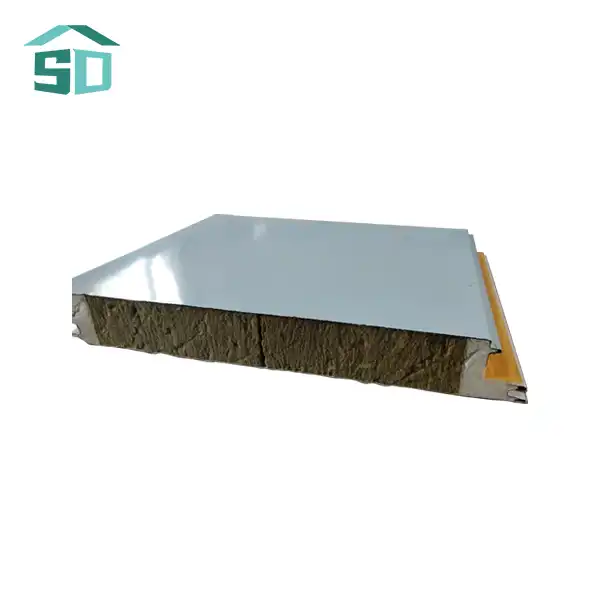

The Layered Design of Aluminum Foam Sandwich Panels

Aluminum foam sandwich panels are engineered with a sophisticated layered structure that contributes to their remarkable properties. These panels typically consist of three main components: two thin, rigid face sheets made of aluminum, and a lightweight core material, often aluminum foam. The face sheets provide strength and durability, while the core material offers insulation and weight reduction. This unique composition allows aluminum foam sandwich panels to combine the best attributes of different materials, resulting in a product that excels in multiple areas of performance.

The Role of Aluminum Foam in Sandwich Panel Construction

The core of aluminum foam sandwich panels plays a crucial role in their overall performance. Aluminum foam, a cellular structure of aluminum with a high porosity, offers several advantages. Its low density contributes to the panel's lightweight nature, making it easier to handle and install. The foam structure also provides excellent thermal insulation properties, helping to regulate temperature within buildings. Additionally, the cellular nature of aluminum foam enhances the panel's ability to absorb energy, making it ideal for applications requiring impact resistance or sound dampening.

Manufacturing Process of Aluminum Foam Sandwich Panels

The production of aluminum foam sandwich panels involves a complex manufacturing process that ensures consistent quality and performance. Aluminum foam sandwich panels suppliers utilize advanced techniques to create the foam core, such as gas injection or powder metallurgy methods. The face sheets are then bonded to the core using adhesives or through a direct foaming process. This manufacturing approach allows for precise control over the panel's thickness, density, and overall properties. The result is a high-quality product that meets the stringent requirements of modern construction projects.

Key Advantages of Using Aluminum Foam Sandwich Panels in Construction

Lightweight Nature and Structural Strength

One of the primary advantages of aluminum foam sandwich panels is their exceptional strength-to-weight ratio. Despite their lightweight nature, these panels offer remarkable structural integrity. This characteristic makes them particularly valuable in construction projects where weight reduction is crucial, such as in high-rise buildings or renovations of existing structures. The use of aluminum foam sandwich panels can significantly reduce the overall load on a building's foundation and supporting elements, potentially leading to cost savings in other aspects of construction.

Thermal Insulation and Energy Efficiency

Aluminum foam sandwich panels excel in providing superior thermal insulation. The foam core acts as an effective barrier against heat transfer, helping to maintain comfortable indoor temperatures with less reliance on heating and cooling systems. This thermal efficiency translates to reduced energy consumption and lower operational costs for buildings. Furthermore, the insulation properties of aluminum foam sandwich panels contribute to a building's overall energy performance, potentially helping it meet or exceed energy efficiency standards and regulations.

Fire Resistance and Safety Features

Safety is a paramount concern in construction, and aluminum foam sandwich panels address this need effectively. These panels often incorporate fire-resistant properties, either through the inherent characteristics of the materials used or through additional treatments. The aluminum face sheets can act as a barrier to flame spread, while the foam core can provide a degree of fire resistance. This combination enhances the overall fire safety of a building, potentially increasing evacuation time in the event of a fire and limiting property damage.

Acoustic Performance and Noise Reduction

In addition to their thermal properties, aluminum foam sandwich panels offer excellent acoustic performance. The foam core's structure is effective at absorbing sound waves, reducing noise transmission between spaces. This characteristic makes aluminum foam sandwich panels particularly valuable in applications such as office buildings, hotels, or residential complexes where sound insulation is crucial for occupant comfort. The improved acoustic environment can contribute to increased productivity in workspaces and enhanced quality of life in living areas.

Applications and Installation of Aluminum Foam Sandwich Panels

Versatility in Architectural Design

Aluminum foam sandwich panels offer architects and designers a high degree of flexibility in creating innovative building facades. These panels can be fabricated in various sizes, shapes, and finishes, allowing for diverse aesthetic expressions. The lightweight nature of aluminum foam sandwich panels enables the creation of bold, cantilevered structures or intricate geometric patterns that might be challenging with traditional materials. This versatility in design opens up new possibilities for architects to push the boundaries of building aesthetics while maintaining structural integrity and performance.

Ease of Installation and Reduced Construction Time

One of the significant advantages of using aluminum foam sandwich panels in construction is the ease and speed of installation. These panels are typically designed as prefabricated units that can be quickly assembled on-site. The lightweight nature of aluminum foam sandwich panels makes them easier to handle and maneuver during installation, reducing the need for heavy lifting equipment. This efficiency in installation can lead to shorter construction timelines, reduced labor costs, and minimized disruption to surrounding areas during the building process.

Long-term Durability and Maintenance Benefits

Aluminum foam sandwich panels are engineered for long-term performance and durability. The aluminum face sheets provide excellent resistance to corrosion and weathering, ensuring that the panels maintain their appearance and structural integrity over time. The foam core is protected from environmental factors, further enhancing the panel's lifespan. This durability translates to reduced maintenance requirements and lower lifecycle costs for buildings. Additionally, the smooth surface of aluminum foam sandwich panels makes them easy to clean and maintain, contributing to the overall aesthetic longevity of the building facade.

Sustainable Construction and Environmental Considerations

As the construction industry increasingly focuses on sustainability, aluminum foam sandwich panels offer several environmental benefits. The lightweight nature of these panels can contribute to reduced transportation emissions during delivery to construction sites. The energy efficiency provided by their insulation properties can lead to lower carbon emissions over the building's lifetime. Furthermore, aluminum is a highly recyclable material, allowing for potential end-of-life recycling of the panels. Some aluminum foam sandwich panels suppliers are also exploring the use of recycled materials in panel production, further enhancing their environmental credentials.

Conclusion

Aluminum foam sandwich panels represent a significant advancement in construction materials, offering a unique combination of lightweight properties, structural strength, and thermal efficiency. Their versatility in design, ease of installation, and long-term durability make them an attractive option for a wide range of building projects. As the construction industry continues to evolve towards more sustainable and efficient practices, aluminum foam sandwich panels are poised to play an increasingly important role in shaping the buildings of the future. By leveraging the advantages of these innovative materials, architects and builders can create structures that are not only aesthetically pleasing but also highly functional and environmentally responsible.

For those interested in exploring the potential of aluminum foam sandwich panels for their construction projects, Weifang Sandong Building Materials Co., Ltd. offers a comprehensive range of high-quality cladding solutions. Our expertise in exterior cladding and facade systems can help you maximize the benefits of aluminum foam sandwich panels in your next building venture. To learn more about our products and services, please contact us at info@sdqsc.com.

FAQ

What are the main benefits of using aluminum foam sandwich panels in construction?

Aluminum foam sandwich panels offer lightweight strength, excellent thermal insulation, fire resistance, and acoustic performance. They are versatile in design, easy to install, and contribute to energy efficiency in buildings.

How do aluminum foam sandwich panels compare to traditional building materials?

Compared to traditional materials, aluminum foam sandwich panels are typically lighter, offer better insulation, and can be installed more quickly. They also provide greater design flexibility and potentially lower long-term maintenance costs.

Are aluminum foam sandwich panels environmentally friendly?

Yes, these panels can contribute to sustainable construction through their energy efficiency, potential for recycling, and the possibility of using recycled materials in their production. Their lightweight nature also reduces transportation emissions.

References

1. Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in materials science, 46(6), 559-632.

2. Ashby, M. F., Evans, T., Fleck, N. A., Hutchinson, J. W., Wadley, H. N. G., & Gibson, L. J. (2000). Metal foams: a design guide. Elsevier.

3. Vinson, J. R. (2018). The behavior of sandwich structures of isotropic and composite materials. Routledge.

4. Zhu, F., Wang, Z., Lu, G., & Zhao, L. (2010). Analytical investigation and optimal design of sandwich panels subjected to shock loading. Materials & Design, 31(4), 2004-2011.

5. Davies, J. M. (Ed.). (2001). Lightweight sandwich construction. John Wiley & Sons.