- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the common materials used in insulated wall panels?

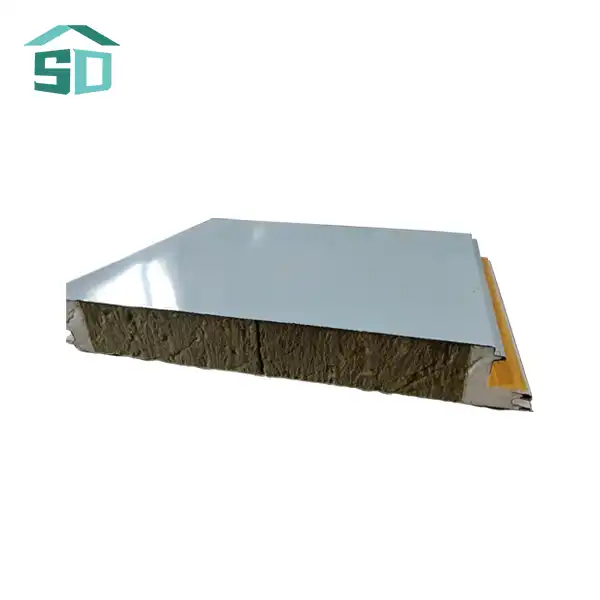

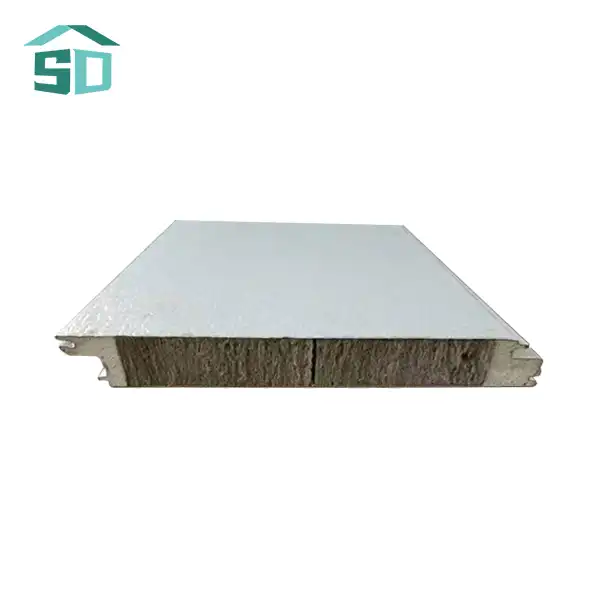

Insulated wall panels are innovative building components that combine superior insulation with structural integrity. These versatile panels typically consist of two outer layers sandwiching an insulating core. The most common materials used in insulated wall panels include metal facings like steel or aluminum, with insulation cores made of polyurethane foam, expanded polystyrene, extruded polystyrene, or mineral wool. Each material offers unique benefits in terms of thermal performance, fire resistance, and durability. Insulated wall panel manufacturers carefully select these materials to create products that meet diverse architectural and functional requirements across residential, commercial, and industrial applications.

Metal Facings: The Protective Outer Layers

Steel: Strength and Durability in Insulated Wall Panels

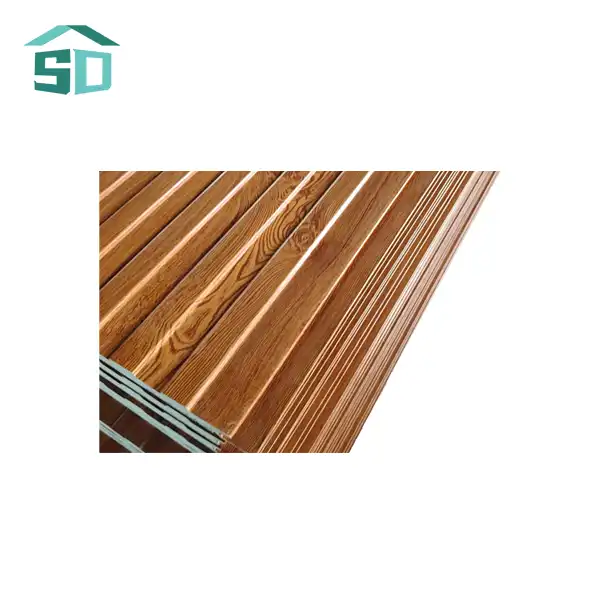

Steel is a popular choice for the outer layers of insulated wall panels due to its exceptional strength and durability. Insulated wall panel manufacturers often use galvanized or pre-painted steel to enhance corrosion resistance. The steel facings provide excellent structural support, allowing the panels to span greater distances without additional framing. This material also offers superior fire resistance, making it ideal for applications where safety is paramount. Steel-faced insulated wall panels are commonly used in industrial buildings, warehouses, and large commercial structures where robustness is essential.

Aluminum: Lightweight Elegance for Insulated Wall Systems

Aluminum facings offer a lightweight alternative for insulated wall panels without compromising on durability. The natural corrosion resistance of aluminum makes it an excellent choice for coastal or high-humidity environments. Aluminum-faced panels are often preferred in architectural applications due to their sleek appearance and wide range of finish options. These panels can be easily fabricated and installed, reducing construction time and labor costs. Insulated wall panel manufacturers frequently use aluminum for projects where weight is a concern, such as in high-rise buildings or retrofitting older structures.

Insulation Core Materials: The Heart of Thermal Performance

Polyurethane Foam: High-Performance Insulation for Wall Panels

Polyurethane foam is widely regarded as one of the most effective insulation materials for insulated wall panels. Its closed-cell structure provides exceptional thermal resistance, with R-values typically ranging from R-6 to R-7 per inch. This high insulation efficiency allows for thinner panel profiles without sacrificing performance. Polyurethane foam also offers excellent moisture resistance and structural stability. Insulated wall panel manufacturers often choose this material for cold storage facilities, food processing plants, and energy-efficient commercial buildings where maintaining consistent temperatures is crucial.

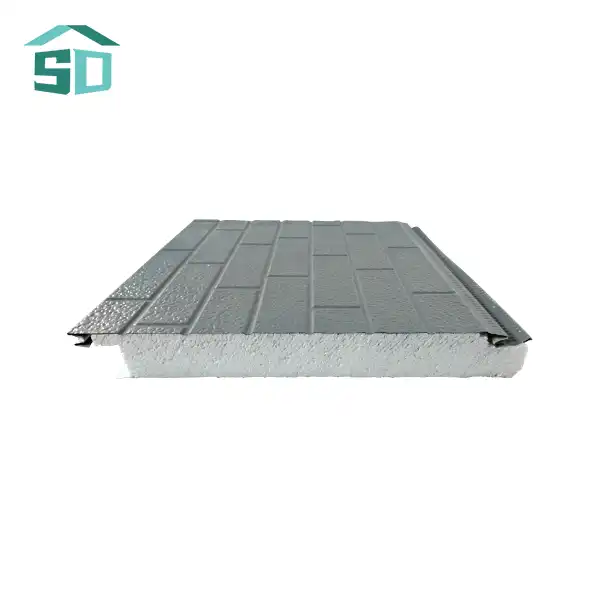

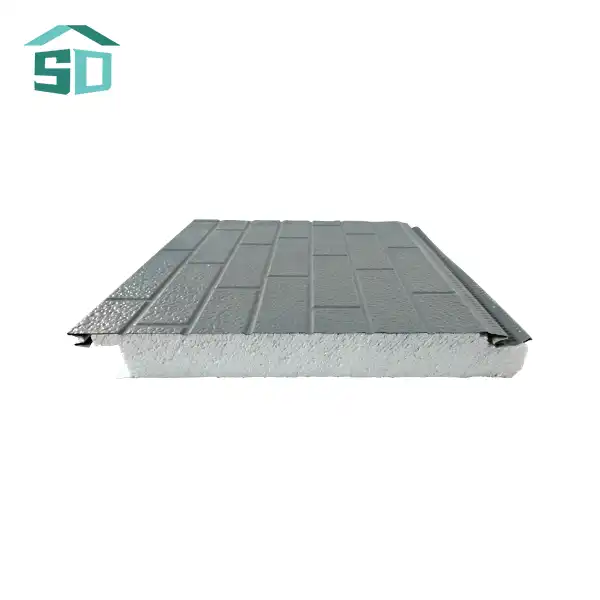

Expanded Polystyrene (EPS): Cost-Effective Insulation Solution

Expanded polystyrene, or EPS, is a lightweight and cost-effective insulation material commonly used in insulated wall panels. While its R-value (typically R-4 per inch) is lower than polyurethane foam, EPS offers good thermal performance at a more affordable price point. This material is also known for its moisture resistance and dimensional stability. Insulated wall panel manufacturers often utilize EPS in residential construction, small commercial buildings, and architectural panels where a balance between performance and cost is desired. EPS-cored panels are also relatively easy to cut and shape on-site, offering flexibility during installation.

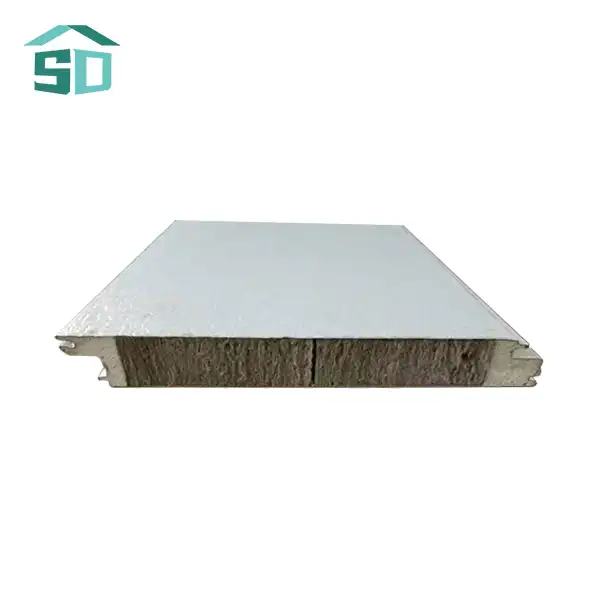

Mineral Wool: Fire-Resistant Insulation for Enhanced Safety

Mineral wool, also known as rock wool or stone wool, is prized for its excellent fire-resistant properties in insulated wall panels. This material is non-combustible and can withstand extremely high temperatures, making it an ideal choice for buildings with stringent fire safety requirements. Mineral wool also provides good sound insulation, enhancing the acoustic performance of wall systems. Insulated wall panel manufacturers often specify mineral wool cores for multi-story buildings, schools, hospitals, and other structures where fire resistance and occupant safety are top priorities. While its R-value (typically R-4 per inch) is comparable to EPS, the added fire protection makes it a preferred choice in many commercial and institutional applications.

Innovations in Insulated Wall Panel Materials

Vacuum Insulated Panels (VIPs): Ultra-Thin, High-Performance Solutions

Vacuum Insulated Panels (VIPs) represent a cutting-edge development in insulated wall panel technology. These panels consist of a micro-porous core material encased in a gas-tight envelope, from which the air has been evacuated. This creates an extremely efficient insulation barrier with R-values that can exceed R-40 per inch, far surpassing traditional insulation materials. While still relatively new to the construction industry, VIPs are gaining traction among insulated wall panel manufacturers for applications where space is at a premium, such as in retrofitting historic buildings or creating ultra-energy-efficient structures. The main challenges with VIPs are their higher cost and the need for careful handling during installation to maintain their vacuum seal.

Phase Change Materials (PCMs): Dynamic Thermal Management

Phase Change Materials (PCMs) are an innovative addition to insulated wall panels, offering dynamic thermal management capabilities. These materials can absorb, store, and release large amounts of latent heat as they change phase from solid to liquid and back. When incorporated into the core of insulated wall panels, PCMs can help regulate indoor temperatures by absorbing excess heat during the day and releasing it at night, reducing the load on HVAC systems. Insulated wall panel manufacturers are exploring PCM-enhanced panels for use in climates with significant daily temperature fluctuations or in buildings with high solar gain. While still in the early stages of adoption, PCMs show promise for further improving the energy efficiency of insulated wall systems.

Conclusion

The diverse range of materials used in insulated wall panels reflects the versatility and adaptability of these building components. From robust steel and lightweight aluminum facings to high-performance insulation cores like polyurethane foam and mineral wool, each material contributes unique properties to the overall panel performance. As technology advances, innovative materials like Vacuum Insulated Panels and Phase Change Materials are pushing the boundaries of what's possible in thermal efficiency and energy management. By carefully selecting and combining these materials, insulated wall panel manufacturers can create tailored solutions to meet the specific needs of any construction project, whether it's prioritizing fire safety, energy efficiency, or architectural aesthetics.

Are you looking for the perfect insulated wall panels for your next construction project? At Weifang Sandong Building Materials Co., Ltd., we offer a wide range of high-quality, customizable insulated wall panels to suit your specific needs. Our expert team can help you choose the ideal combination of materials for optimal performance and aesthetics. Contact us today at info@sdqsc.com to learn more about our products and how we can enhance your building's efficiency and appearance with our state-of-the-art insulated wall panels.

FAQ

What are the advantages of using insulated wall panels?

Insulated wall panels offer numerous benefits, including improved energy efficiency, faster installation times, and enhanced structural integrity. They provide excellent thermal insulation, reducing heating and cooling costs, while also offering sound dampening properties. Their prefabricated nature allows for quicker construction and reduced on-site labor.

How long do insulated wall panels typically last?

The lifespan of insulated wall panels can vary depending on the materials used and environmental conditions, but they generally last 30-50 years with proper maintenance. High-quality panels from reputable manufacturers often come with warranties ranging from 10 to 30 years.

Can insulated wall panels be used in both residential and commercial construction?

Yes, insulated wall panels are versatile and can be used in both residential and commercial construction projects. They are particularly popular in commercial and industrial buildings due to their energy efficiency and quick installation, but are increasingly being used in modern residential designs as well.

References

1. Cabeza, L. F., et al. (2011). Materials used as PCM in thermal energy storage in buildings: A review. Renewable and Sustainable Energy Reviews, 15(3), 1675-1695.

2. Jelle, B. P. (2011). Traditional, state-of-the-art and future thermal building insulation materials and solutions – Properties, requirements and possibilities. Energy and Buildings, 43(10), 2549-2563.

3. Kingspan Group. (2021). Insulated Panel Systems: Technical Manual.

4. Metecno. (2020). Insulated Panels Technical Manual.

5. Payette, T., & Paya-Marin, M. A. (2018). Vacuum insulated panels (VIPs) in building applications. In Materials for Energy Efficiency and Thermal Comfort in Buildings (pp. 693-728). Woodhead Publishing.