Proper Alignment and Sealing Techniques

Achieving Perfect Panel Alignment

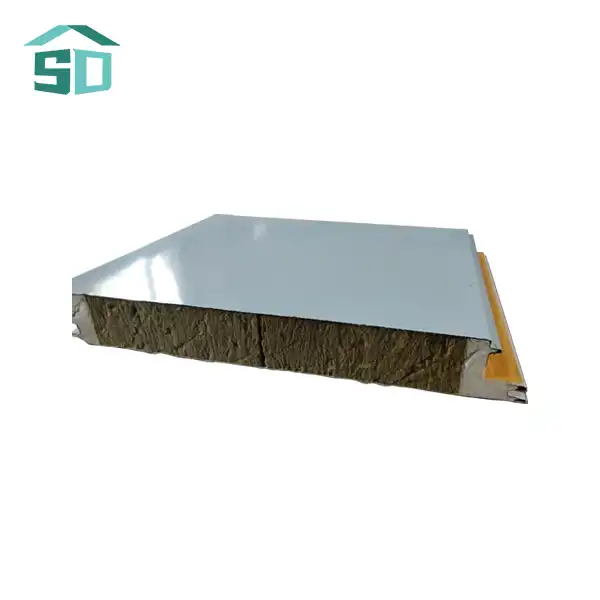

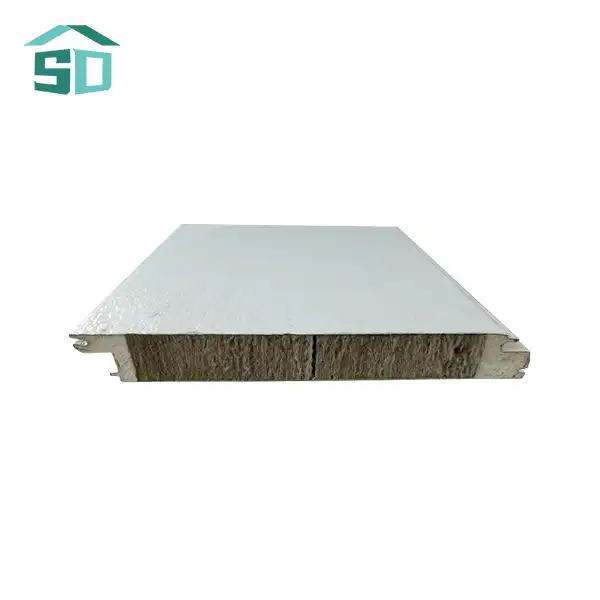

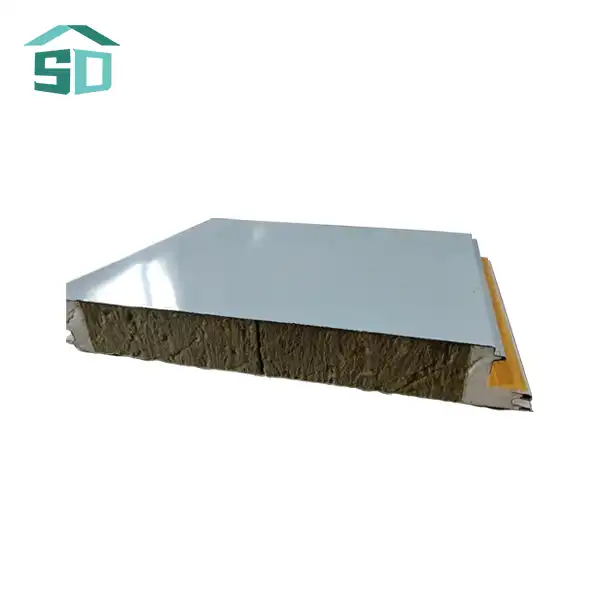

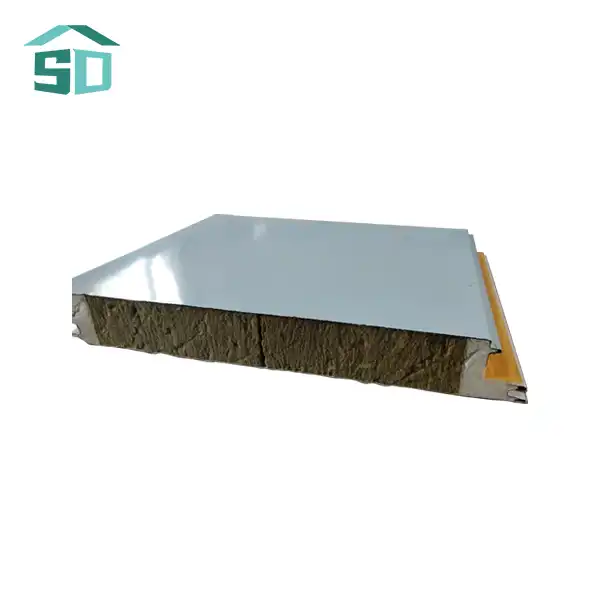

One of the primary challenges in installing insulated wall panels is achieving proper alignment. Misaligned panels not only compromise the aesthetic appeal of the building but can also lead to gaps that reduce energy efficiency. To overcome this challenge, installers must use precise measuring tools and employ a systematic approach. It's crucial to start with a level base and work methodically, constantly checking alignment both vertically and horizontally. Some advanced insulated wall panels come with interlocking systems that can aid in alignment, but even these require careful handling to ensure a seamless fit.

Effective Sealing Methods for Insulated Wall Panels

Proper sealing is paramount in insulated wall panel installation. Inadequate sealing can lead to air and moisture infiltration, negating the energy-saving benefits of the panels. Installers must pay close attention to all joints, edges, and intersections. High-quality sealants compatible with the panel material should be used generously yet precisely. Some manufacturers provide specialized sealants designed specifically for their insulated wall panels, which can ensure optimal performance. Additionally, installers should be aware of environmental conditions during installation, as temperature and humidity can affect sealant efficacy.

Managing Thermal Bridging Issues

Identifying Potential Thermal Bridges

Thermal bridging occurs when there is a discontinuity in the insulation layer, creating a pathway for heat to escape or enter a building more easily. In insulated wall panel installations, these weak points are most commonly found at panel joints, corners, window perimeters, and door openings. If not properly addressed, they can compromise energy efficiency, increase heating and cooling costs, and lead to condensation issues. Careful detailing, sealing, and the use of thermal break materials are essential to minimize these effects. Identifying these potential weak points is crucial before and during installation. Installers should conduct thorough thermal imaging scans to detect any inconsistencies in insulation performance. This proactive approach allows for adjustments to be made before the installation is complete, ensuring optimal thermal efficiency of the insulated wall panels.

Implementing Solutions to Minimize Thermal Bridging

Once potential thermal bridges are identified, implementing effective solutions is key to maintaining the overall thermal efficiency of the building envelope. This often involves applying supplementary insulation materials at junctions, corners, and fastening points where heat loss is most likely to occur. For example, installing thermal break strips between the insulated wall panels and the building structure significantly minimizes unwanted heat transfer, ensuring improved energy performance, durability, and indoor comfort. In corners and around openings, specialized insulated corner pieces and pre-insulated frames can be used. Some advanced insulated wall panels come with built-in thermal break technologies, which can significantly simplify this aspect of installation. Installers should also pay attention to the fastening methods used, as certain types of fasteners can create thermal bridges if not properly selected or installed.

Panel Sizing and Customization Challenges

Accurate Measurement and Cutting of Insulated Wall Panels

Ensuring accurate panel sizing is a critical challenge in insulated wall panel installation. Panels often need to be cut to fit specific dimensions or to accommodate openings for windows, doors, and utilities. This requires precise measurements and skillful cutting techniques. Incorrect sizing can lead to gaps, overlaps, or the need for extensive on-site modifications, all of which can compromise the panel's performance and appearance. Installers should use high-quality measuring tools and cutting equipment designed specifically for insulated wall panels. Some manufacturers offer custom sizing services, which can greatly reduce on-site cutting and ensure a more precise fit.

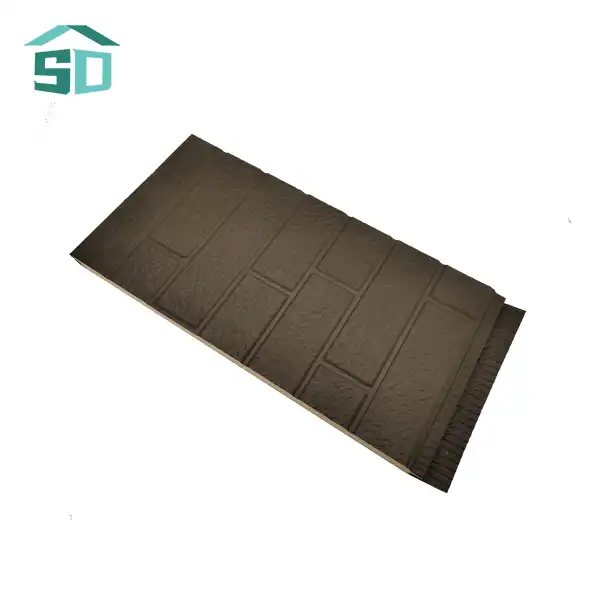

Adapting Panels for Unique Architectural Features

Modern architecture often incorporates unique features that can pose challenges for insulated wall panel installation. Curved walls, angled surfaces, and non-standard shapes require careful planning and sometimes custom fabrication. Installers may need to work closely with manufacturers to create specially designed panels that fit these unique requirements. In some cases, it may be necessary to use a combination of standard panels and custom-cut pieces to achieve the desired result. This process demands a high level of skill and often requires specialized tools and techniques to ensure that the customized panels maintain their insulative properties and structural integrity.

Conclusion

Installing insulated wall panels presents various challenges, from alignment and sealing to managing thermal bridging and customization. Partnering with a reliable insulated wall panels manufacturer can help ensure precision engineering, consistent quality, and tailored solutions that address these installation concerns effectively. However, with proper planning, skilled craftsmanship, and attention to detail, these challenges can be effectively overcome. The key lies in understanding the specific requirements of each project and choosing the right products and installation methods. As the demand for energy-efficient building solutions continues to grow, insulated wall panel manufacturers are constantly innovating to address these installation challenges, making the process more streamlined and efficient.

For those seeking high-quality, easy-to-install insulated wall panels, Weifang Sandong Building Materials Co., Ltd. offers a range of solutions designed to meet diverse architectural needs while simplifying the installation process. Our panels combine aesthetic appeal with advanced insulation properties, fire safety features, and corrosion resistance. To learn more about our products or to discuss your specific project requirements, please contact us at info@sdqsc.com.

FAQ

How long does it typically take to install insulated wall panels?

Installation time varies depending on the project size and complexity, but generally, insulated wall panels can be installed more quickly than traditional construction methods. A skilled team can often complete the exterior of a small to medium-sized building in a matter of days.

Can insulated wall panels be installed in any climate?

Yes, insulated wall panels are designed to perform well in various climates. However, the specific type of panel and installation method may need to be adjusted based on local weather conditions and building codes.

Are special tools required for installing insulated wall panels?

While some standard construction tools are used, specialized cutting tools and lifting equipment may be necessary for efficient and precise installation of insulated wall panels.

References

1.Building Science Corporation. (2021). "Thermal Bridging Solutions in Exterior Wall Construction."

2.National Institute of Building Sciences. (2020). "Whole Building Design Guide: Building Envelope Design Guide."

3.American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2019). "ASHRAE Handbook - Fundamentals." Atlanta, GA: ASHRAE.

4.International Code Council. (2021). "International Energy Conservation Code."