The Science Behind Aluminum Foam Sandwich Panels

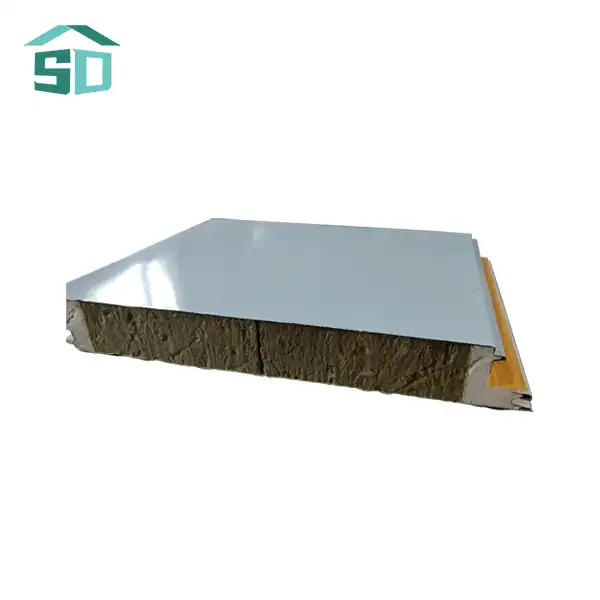

Aluminum foam sandwich panels are a marvel of modern engineering, combining the strength of aluminum with the acoustic properties of foam. These panels consist of two thin, dense aluminum face sheets bonded to a lightweight aluminum foam core. The foam core is created through a specialized manufacturing process that introduces gas bubbles into molten aluminum, resulting in a porous structure.

This unique composition gives aluminum foam sandwich panels several advantageous properties:

Acoustic Performance

The porous nature of the aluminum foam core acts as an excellent sound absorber. When sound waves encounter the foam, they are partially converted into heat energy through friction within the foam's cellular structure. This process effectively reduces the intensity of sound transmission through the panel.

Structural Integrity

Despite their lightweight nature, aluminum foam sandwich panels exhibit remarkable strength-to-weight ratios. The aluminum face sheets provide rigidity and durability, while the foam core contributes to overall structural stability. This combination results in panels that are both sturdy and easy to handle during installation.

Thermal Insulation

In addition to their soundproofing capabilities, these panels offer excellent thermal insulation properties. The air pockets within the foam core act as barriers to heat transfer, helping to maintain consistent temperatures within the soundproofed space.

Installation and Application of Aluminum Foam Panels

Installing aluminum foam sandwich panels for soundproofing purposes is a relatively straightforward process, making them an attractive option for both professional contractors and DIY enthusiasts. The lightweight nature of these panels facilitates easy handling and positioning, reducing installation time and labor costs.

Preparation and Mounting

Before installation, it's crucial to ensure that the existing walls or surfaces are clean, dry, and free from any structural defects. The panels can be mounted using various methods, including adhesive bonding, mechanical fasteners, or a combination of both. For optimal soundproofing results, it's recommended to create an air gap between the existing wall and the aluminum foam panel.

Customization Options

One of the key advantages of aluminum foam sandwich panels is their versatility in design. These panels can be easily cut and shaped to fit specific room dimensions or to accommodate fixtures such as windows and doors. Additionally, the aluminum face sheets can be finished in a variety of colors and textures, allowing for seamless integration with existing décor.

Maintenance and Longevity

Aluminum foam sandwich panels are known for their durability and low maintenance requirements. The aluminum face sheets are resistant to corrosion and can be easily cleaned with standard household products. With proper installation and care, these panels can provide effective soundproofing for many years, making them a cost-effective long-term solution.

Benefits and Considerations for Soundproof Room Design

When incorporating aluminum foam sandwich panels into soundproof room design, several benefits and considerations come into play:

Enhanced Acoustic Environment

The primary benefit of using these panels is the significant improvement in acoustic quality. By effectively absorbing and dampening sound waves, aluminum foam panels create an environment with reduced echo and reverberation. This is particularly valuable in spaces where clear audio is crucial, such as recording studios or lecture halls.

Energy Efficiency

The thermal insulation properties of aluminum foam sandwich panels contribute to improved energy efficiency. By helping to maintain consistent indoor temperatures, these panels can reduce the load on heating and cooling systems, potentially leading to lower energy costs.

Fire Safety

Many aluminum foam sandwich panels are designed with fire safety in mind. The inherent properties of aluminum, combined with specialized treatments, can result in panels that meet stringent fire resistance standards. This is an important consideration for both residential and commercial applications.

Cost Considerations

While the initial cost of aluminum foam sandwich panels may be higher compared to some traditional soundproofing materials, their long-term benefits often justify the investment. Factors such as durability, energy efficiency, and reduced maintenance needs contribute to their cost-effectiveness over time.

Environmental Impact

Aluminum is a highly recyclable material, and many manufacturers are focusing on sustainable production methods for aluminum foam sandwich panels. When considering these panels for a project, it's worth exploring options that align with environmental sustainability goals.

Conclusion

Aluminum foam sandwich panels represent a cutting-edge solution for creating soundproof rooms. Their unique combination of acoustic performance, structural integrity, and versatility makes them an excellent choice for a wide range of applications. From enhancing the audio quality in professional studios to creating peaceful living spaces in urban environments, these panels offer a balance of functionality and efficiency. As technology continues to advance, we can expect further innovations in aluminum foam panel design, potentially expanding their capabilities and applications in soundproofing and beyond.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of quality and innovation in exterior cladding and facade solutions. Our aluminum foam sandwich panels are designed to meet the highest standards of performance and aesthetics. Whether you're working on a new construction project or renovating an existing space, our expert team is ready to assist you in finding the perfect soundproofing solution. For more information on our products and how they can benefit your project, please contact us at info@sdqsc.com.

FAQ

How effective are aluminum foam sandwich panels in soundproofing compared to traditional materials?

Aluminum foam sandwich panels are highly effective, often outperforming traditional materials due to their unique cellular structure that absorbs sound waves efficiently.

Can aluminum foam panels be used in both residential and commercial settings?

Yes, these panels are versatile and suitable for various applications, including homes, offices, studios, and industrial spaces.

Are aluminum foam sandwich panels environmentally friendly?

Many manufacturers focus on sustainable production, and aluminum is highly recyclable, making these panels a more eco-friendly option compared to some alternatives.

References

1.Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science, 46(6), 559-632.

2.Ashby, M. F., Evans, A., Fleck, N. A., Gibson, L. J., Hutchinson, J. W., & Wadley, H. N. (2000). Metal foams: a design guide. Elsevier.

3.García-Moreno, F. (2016). Commercial applications of metal foams: Their properties and production. Materials, 9(2), 85.

4.Acoustic Society of America. (2022). Sound Absorption and Sound Absorbing Materials.

5.U.S. Department of Energy. (2021). Insulation Materials. Energy Saver.