Understanding Corrugated Sandwich Panels: Composition and Properties

The Anatomy of Corrugated Sandwich Panels

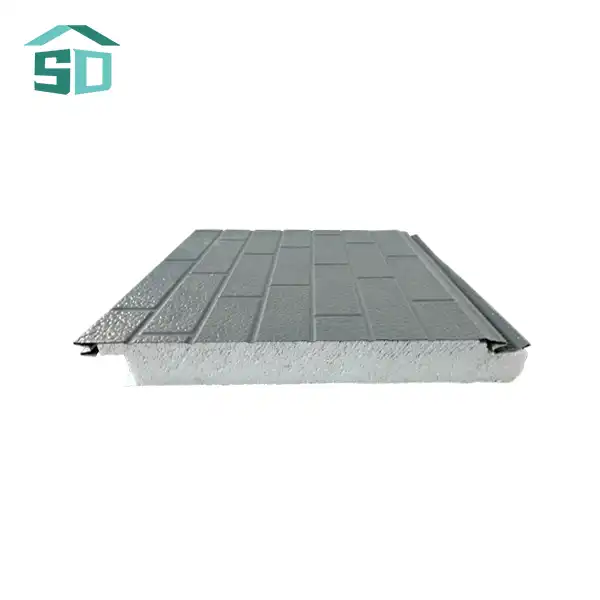

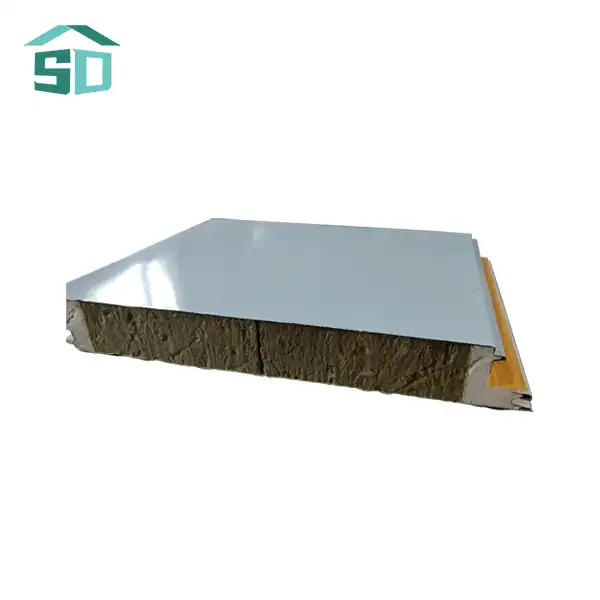

Corrugated sandwich panels are engineered building materials consisting of three main components: two outer facings and an insulating core. The outer layers are typically made of metal sheets, such as steel or aluminum, with a corrugated profile that enhances strength and rigidity. The core material, sandwiched between these facings, is usually a high-performance insulator like polyurethane foam, expanded polystyrene, or mineral wool.

The unique structure of these panels offers several advantages:

- Structural Integrity: The corrugated design of the outer facings provides exceptional strength-to-weight ratio, allowing the panels to span large distances without additional support.

- Thermal Insulation: The core material acts as an effective barrier against heat transfer, significantly improving the energy efficiency of buildings.

- Acoustic Performance: Depending on the core material used, these panels can also offer sound insulation properties, reducing noise transmission between spaces.

- Moisture Resistance: The metal facings and sealed edges protect the insulation core from moisture ingress, enhancing durability and longevity.

Manufacturing Process and Quality Control

The production of corrugated sandwich panelinvolves a sophisticated manufacturing process that ensures consistent quality and performance. At Weifang Sandong Building Materials Co., Ltd., we utilize advanced production lines and rigorous quality control systems to produce top-tier panels. Our process includes:

- Meticulous inspection of raw materials, including steel coils, aluminum foil, and polyurethane components.

- Precise control of panel thickness, paint film application, and overall dimensions.

- Comprehensive testing of mechanical strength, flame retardancy, and aesthetic appearance.

This attention to detail guarantees that each panel meets stringent industry standards and customer expectations.

Applications and Benefits of Corrugated Sandwich Panels

Versatility in Construction

Corrugated sandwich panels have found widespread use across various construction sectors due to their adaptability and performance. Some common applications include:

- Industrial Buildings: Warehouses, factories, and storage facilities benefit from the panels' thermal efficiency and rapid installation.

- Commercial Structures: Offices, retail spaces, and sports facilities utilize these panels for their aesthetic appeal and energy-saving properties.

- Residential Projects: Modern homes and apartment complexes incorporate sandwich panels for their sleek appearance and excellent insulation.

- Agricultural Buildings: Barns, greenhouses, and storage sheds leverage the durability and weather resistance of these panels.

- Cold Storage Facilities: The superior insulation properties make these panels ideal for maintaining controlled temperatures in refrigerated spaces.

Key Advantages for Builders and Property Owners

The adoption of corrugated sandwich paneloffers numerous benefits:

- Energy Efficiency: The high insulation value of these panels contributes to significant energy savings in heating and cooling costs.

- Rapid Installation: Prefabricated panels allow for quick and straightforward on-site assembly, reducing construction time and labor costs.

- Lightweight Construction: The panels' low weight compared to traditional building materials reduces the load on the building's structure, potentially lowering foundation costs.

- Durability: Resistant to corrosion, weathering, and UV radiation, these panels offer long-term performance with minimal maintenance.

- Design Flexibility: Available in various colors, finishes, and profiles, corrugated sandwich panels provide architects with ample design options.

- Fire Resistance: Many panels are engineered to meet stringent fire safety standards, enhancing building safety.

Selecting and Installing Corrugated Sandwich Panels

Factors to Consider When Choosing Panels

When selecting corrugated sandwich panels for a project, several factors should be taken into account:

- Insulation Requirements: Consider the climate and building use to determine the necessary R-value for optimal energy efficiency.

- Structural Loads: Assess the panels' ability to withstand wind, snow, and other environmental factors specific to the building's location.

- Aesthetic Preferences: Choose from a range of colors and finishes to complement the overall architectural design.

- Fire Performance: Ensure the selected panels meet local building codes and fire safety regulations.

- Environmental Considerations: Opt for panels with recyclable components or those manufactured using sustainable practices.

Best Practices for Installation

Proper installation is crucial for maximizing the performance and longevity of corrugated sandwich panel. Key considerations include:

- Panel Handling: Use appropriate lifting equipment and follow manufacturer guidelines to prevent damage during transport and installation.

- Joint Sealing: Ensure all joints and connections are properly sealed to maintain insulation integrity and prevent water infiltration.

- Fastening Systems: Use compatible fasteners and follow recommended spacing to secure panels without compromising their structural integrity.

- Thermal Bridging: Address potential thermal bridges at panel connections and building interfaces to maximize energy efficiency.

- Expansion and Contraction: Allow for thermal movement by following manufacturer guidelines for panel spacing and attachment.

Maintenance and Long-Term Care

While corrugated sandwich panels are low-maintenance, regular upkeep can extend their lifespan:

- Periodic Inspections: Check for any signs of damage, loose fasteners, or sealant degradation.

- Cleaning: Regularly remove dirt and debris using mild detergents and soft brushes to maintain appearance and prevent potential damage.

- Repainting: If necessary, repaint panels following manufacturer recommendations to refresh aesthetics and maintain protective coatings.

Conclusion

Corrugated sandwich panelrepresents a pinnacle of modern construction materials, offering an unparalleled combination of strength, insulation, and versatility. Their ability to enhance energy efficiency, expedite construction timelines, and provide aesthetic flexibility makes them an invaluable asset in today's building industry. As we've explored in this guide, the careful selection, proper installation, and ongoing maintenance of these panels can significantly contribute to the success and longevity of various construction projects.

At Weifang Sandong Building Materials Co., Ltd., we're committed to delivering high-quality corrugated sandwich panels that meet the evolving needs of the construction industry. Our focus on innovation, sustainability, and customer satisfaction drives us to continually improve our products and services. Whether you're planning a new build, renovation, or seeking to enhance your building's energy performance, our team of experts is here to assist you in choosing the ideal sandwich panel solution. For personalized advice or to learn more about our product range, please don't hesitate to contact us at info@sdqsc.com.

FAQ

What makes corrugated sandwich panels energy-efficient?

The insulating core material, combined with the sealed construction, significantly reduces heat transfer, improving overall building energy efficiency.

Are corrugated sandwich panels suitable for residential construction?

Yes, these panels are increasingly used in modern residential projects due to their excellent insulation properties and aesthetic versatility.

How long do corrugated sandwich panels typically last?

With proper installation and maintenance, these panels can last 30 years or more, depending on environmental conditions and usage.

References

1.European Association for Panels and Profiles. (2021). "Sandwich Panels in Construction: A Comprehensive Guide."

2.American Society of Civil Engineers. (2020). "Structural Design of Metal Building Systems."

3.International Journal of Engineering Research and Technology. (2019). "Advancements in Corrugated Sandwich Panel Technology for Sustainable Construction."

4.Building Science Corporation. (2018). "Thermal Performance of Building Envelope Systems: An Analysis of Modern Insulation Technologies."

5.Journal of Architectural Engineering. (2022). "Long-term Performance and Durability of Corrugated Sandwich Panels in Various Climate Conditions."