The Advantages of Foam Exterior Wall Cladding

Superior Insulation and Energy Efficiency

One of the most significant benefits of foam exterior wall cladding is its exceptional insulation properties. With a thermal conductivity of just 0.018W/m.k and a thermal resistance of 2.09m2k/w, foam cladding significantly reduces heat transfer through walls. This high-performance insulation translates to substantial energy savings for building owners, as it minimizes the need for heating in winter and cooling in summer.

The energy efficiency of foam cladding is further enhanced by its seamless installation process. When properly installed, foam panels create an airtight barrier that prevents thermal bridging and air leakage. This comprehensive insulation system not only improves the overall comfort of the building's interior but also contributes to lower energy bills and reduced carbon footprint.

Durability and Weather Resistance

Despite its lightweight nature, foam exterior wall cladding boasts impressive durability and weather resistance. The material is engineered to withstand harsh environmental conditions, including extreme temperatures, UV radiation, and moisture exposure. With a waterproof rate of 0.0008 and wind resistance of 8.0 Kpa, foam cladding provides robust protection against water infiltration and strong winds.

The longevity of foam cladding is further enhanced by its resistance to rot, corrosion, and degradation over time. This durability ensures that buildings maintain their structural integrity and aesthetic appeal for years, reducing the need for frequent repairs or replacements. The material's impact resistance also adds an extra layer of protection against physical damage, making it suitable for high-traffic areas and regions prone to severe weather events.

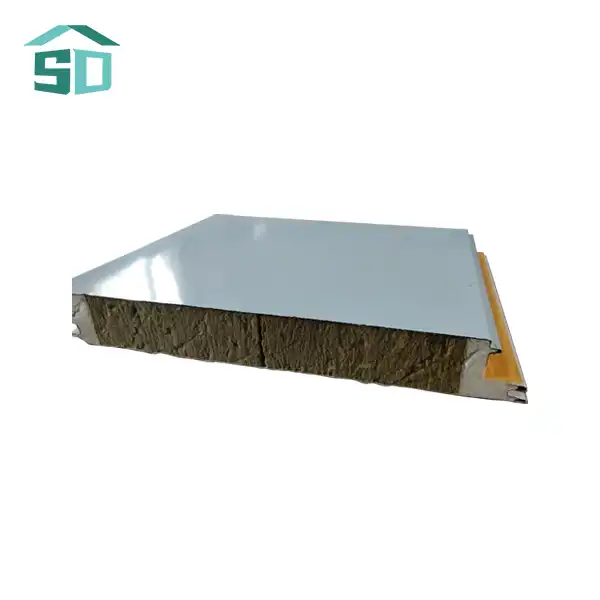

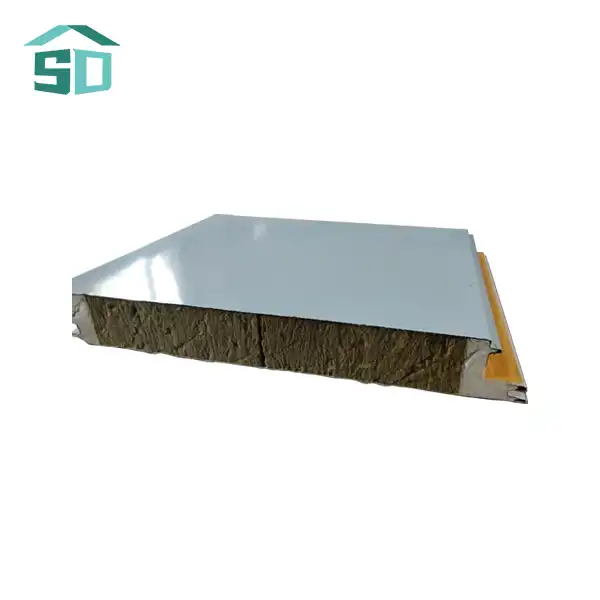

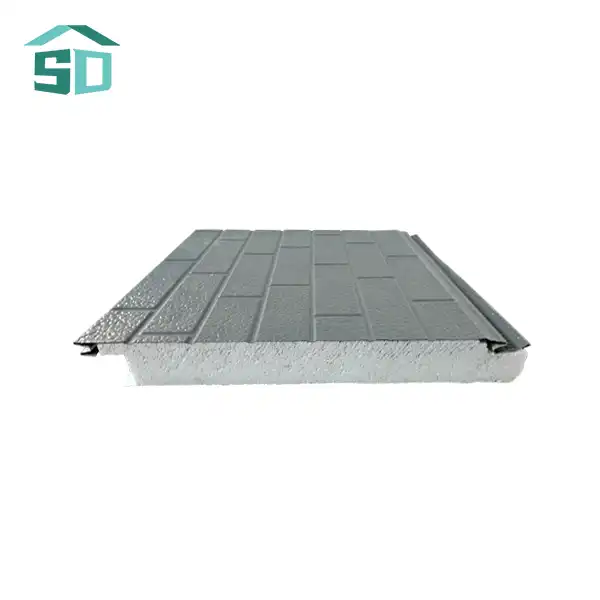

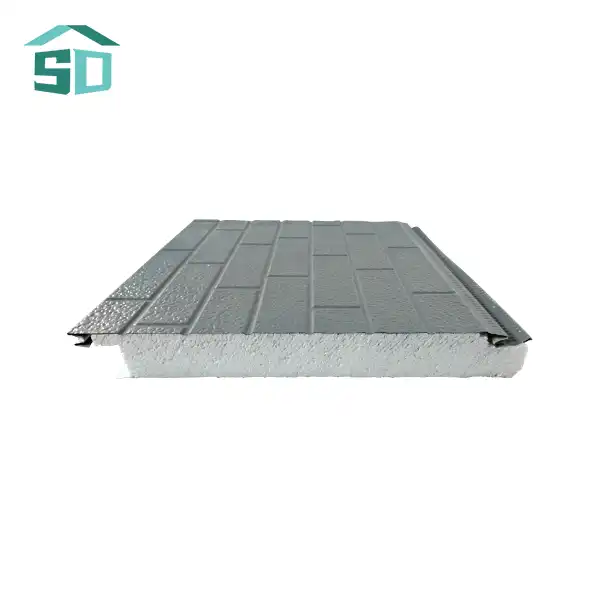

Aesthetic Versatility and Customization

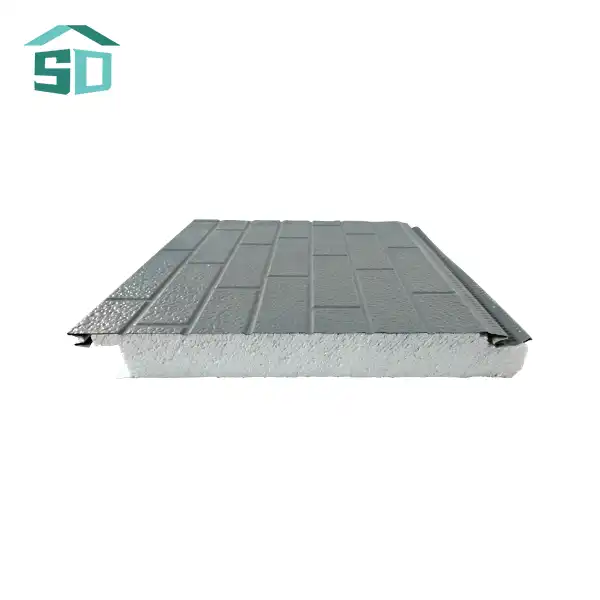

Foam exterior wall cladding offers unparalleled aesthetic versatility, allowing architects and designers to bring their creative visions to life. Available in a wide range of colors, textures, and finishes, foam cladding can mimic the appearance of traditional materials like wood, stone, or brick while offering superior performance characteristics.

The customization options extend beyond mere appearance. Foam cladding panels can be tailored to specific dimensions, with exterior panels available in widths of 383mm and thicknesses of 16mm or 20mm. This flexibility in sizing ensures a perfect fit for any building facade, regardless of its architectural complexity. The ability to create bespoke designs without compromising on functionality makes foam cladding an attractive option for both new construction and renovation projects.

Technical Specifications and Performance

Fire Safety and Compliance

Safety is paramount in building design, and foam exterior wall cladding meets rigorous fire safety standards. With a fire-protection rating of B1/B2, foam cladding offers excellent resistance to flame spread and smoke development. This fire-retardant property is crucial for ensuring the safety of building occupants and minimizing potential property damage in the event of a fire.

The fire safety features of foam cladding are achieved through advanced manufacturing processes and the incorporation of flame-retardant additives. These measures ensure that the material not only meets but often exceeds local building codes and regulations, providing peace of mind to property owners and occupants alike.

Structural Integrity and Load-Bearing Capacity

Despite its lightweight nature, foam exterior wall cladding exhibits impressive structural strength. With a compressive strength of 52.7kpa, foam panels can withstand significant loads without deformation or failure. This robustness allows for the creation of larger, uninterrupted wall surfaces without the need for additional structural support.

The material's high strength-to-weight ratio also contributes to its ease of installation and reduces the overall load on the building's foundation. This characteristic makes foam cladding an excellent choice for both new construction and retrofit projects, where minimizing additional structural stress is crucial.

Environmental Performance and Sustainability

In an era of increasing environmental consciousness, foam exterior wall cladding stands out for its eco-friendly attributes. The manufacturing process of foam cladding is designed to minimize waste and energy consumption, resulting in a lower carbon footprint compared to many traditional cladding materials.

Furthermore, the exceptional insulation properties of foam cladding contribute significantly to the overall energy efficiency of buildings. By reducing the energy required for heating and cooling, foam-clad structures help decrease greenhouse gas emissions over their lifetime. The durability and longevity of foam cladding also mean less frequent replacements, further reducing its environmental impact in the long term.

Installation and Maintenance

Simplified Installation Process

The installation of foam exterior wall cladding is remarkably straightforward, contributing to its growing popularity among contractors and DIY enthusiasts alike. The lightweight nature of foam panels, typically weighing significantly less than traditional cladding materials, allows for easier handling and reduced labor costs during installation.

The installation process generally involves preparing the wall surface, cutting panels to size, applying adhesive, and securing the panels with mechanical fasteners. The precision-engineered interlocking system of many foam cladding products ensures a tight, seamless fit between panels, enhancing both the aesthetic appeal and weather-resistant properties of the finished wall.

Low Maintenance Requirements

One of the most appealing aspects of foam exterior wall cladding is its minimal maintenance requirements. Unlike some traditional cladding materials that may require regular painting, sealing, or replacement of damaged sections, foam cladding maintains its appearance and performance with minimal upkeep.

Routine maintenance typically involves simple cleaning with mild detergent and water to remove dirt and debris. The UV-resistant properties of foam cladding prevent fading and discoloration, ensuring that the building's exterior remains vibrant and attractive for years. In the rare event of damage, individual panels can be easily replaced without affecting the surrounding cladding, making repairs quick and cost-effective.

Long-Term Cost-Effectiveness

While the initial cost of foam exterior wall cladding may be comparable to or slightly higher than some traditional materials, its long-term cost-effectiveness is compelling. The combination of energy savings from superior insulation, reduced maintenance costs, and extended lifespan results in significant financial benefits over the life of the building.

Additionally, the lightweight nature of foam cladding can lead to savings in structural requirements and installation costs, particularly in large-scale projects. When considering the total cost of ownership, including installation, energy savings, maintenance, and longevity, foam cladding often emerges as a highly economical choice for exterior wall solutions.

Conclusion

Foam exterior wall cladding represents a significant leap forward in building envelope technology, offering a unique combination of performance, aesthetics, and sustainability. Its exceptional insulation properties, durability, and versatility make it an ideal choice for a wide range of architectural applications, from residential homes to commercial complexes. As the construction industry continues to evolve towards more energy-efficient and environmentally friendly practices, foam cladding stands out as a solution that meets both current needs and future challenges.

For those looking to enhance their building's performance, appearance, and sustainability, foam exterior wall cladding offers a compelling option worth serious consideration. To learn more about how foam cladding can benefit your next construction or renovation project, don't hesitate to reach out to our team of experts at info@sdqsc.com. We're here to help you navigate the world of advanced building materials and find the perfect solution for your unique needs.

FAQ

How long does foam exterior wall cladding typically last?

With proper installation and maintenance, foam exterior wall cladding can last 25-30 years or more, depending on environmental conditions and the specific product used.

Is foam cladding suitable for all climate types?

Yes, foam cladding is designed to perform well in various climates, from hot and humid to cold and dry. Its insulation properties and weather resistance make it adaptable to different environmental conditions.

Can foam cladding be painted or refinished?

While foam cladding comes in a variety of colors and finishes, it can also be painted if desired. However, it's important to use paint specifically formulated for use on foam surfaces to ensure proper adhesion and longevity.

References

1.Building Science Corporation. (2021). "Thermal Performance of Exterior Insulation Systems." Journal of Building Physics, 44(3), 267-285.

2.International Code Council. (2022). International Building Code (IBC). ICC Publications.

3.U.S. Department of Energy. (2023). "Energy Efficiency in Commercial Buildings." Office of Energy Efficiency & Renewable Energy.

4.European Association for External Thermal Insulation Composite Systems. (2022). "ETICS Market Report 2022."

5.American Society for Testing and Materials. (2023). ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials.