The Fusion of Form and Function: Aluminum Foam Sandwich Panels in Modern Architecture

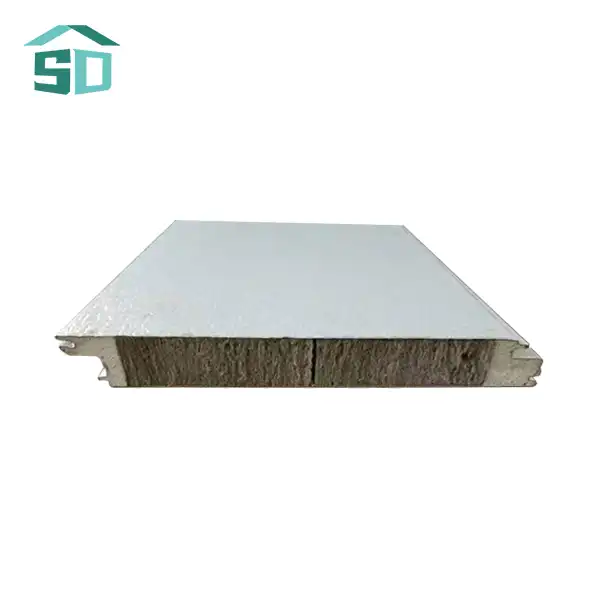

Aluminum foam sandwich panels represent a groundbreaking advancement in building materials, seamlessly blending aesthetic appeal with practical benefits. These panels consist of a lightweight aluminum foam core sandwiched between two thin aluminum sheets, creating a structure that's both robust and remarkably light.

The unique composition of these panels offers a myriad of advantages for architectural applications. Their core durability is unmatched, providing exceptional strength despite their lightweight nature. This allows architects to design bold, expansive structures without compromising on stability or safety.

Thermal Efficiency: A Game-Changer in Building Design

One of the standout features of aluminum foam sandwich panels is their superior thermal efficiency. With a thermal conductivity of just 0.018W/m.k and a thermal resistance of 2.09m2k/w, these panels offer exceptional insulation properties. This translates to significant energy savings for buildings, reducing heating and cooling costs while maintaining comfortable interior temperatures year-round.

The impressive insulation capabilities of these panels make them an ideal choice for both residential and commercial buildings. They help create energy-efficient spaces that not only reduce operational costs but also contribute to a more sustainable built environment.

Fire-Resistant Design: Prioritizing Safety in Architecture

Safety is paramount in architectural design, and aluminum foam sandwich panels excel in this aspect. With a fire-protection rating of B1/B2, these panels offer robust fire resistance, enhancing the overall safety of buildings. This feature is particularly crucial for high-rise structures and public buildings where fire safety is a top priority.

The non-flammable nature of these panels provides an added layer of protection, potentially slowing the spread of fire and allowing more time for evacuation in emergency situations. This combination of safety and performance makes aluminum foam sandwich panels a preferred choice for architects and builders who prioritize both aesthetics and occupant safety.

Versatility in Design: Unleashing Creativity with Aluminum Foam Panels

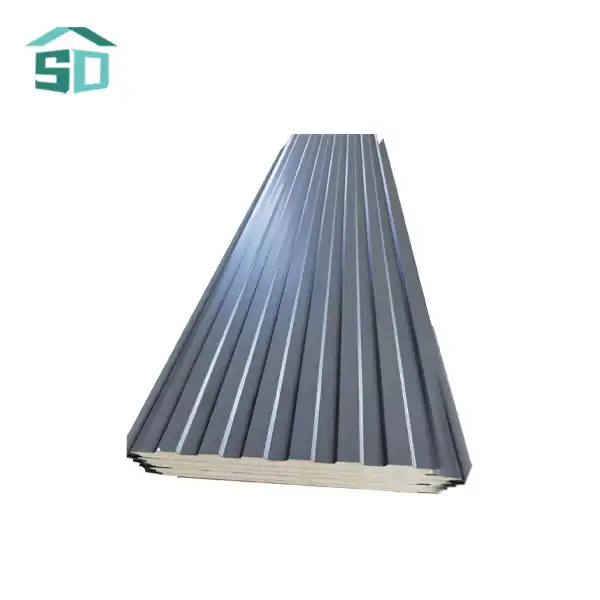

The adaptability of aluminum foam sandwich panels opens up a world of design possibilities for architects. These panels can be easily customized in terms of colors, patterns, and finishes, allowing for unparalleled creative expression in building facades and interiors.

Whether it's a sleek, monochromatic look for a modern office building or a vibrant, patterned exterior for a cultural center, these panels can be tailored to suit any architectural vision. Their versatility extends to both interior and exterior applications, making them a versatile solution for various design challenges.

Weatherproof Wonder: Corrosion-Free Performance

Aluminum foam sandwich panels boast impressive corrosion resistance, ensuring long-lasting beauty even in harsh environmental conditions. With a waterproof rate of 0.0008 and wind resistance of 8.0 Kpa, these panels are built to withstand the elements.

This durability makes them an excellent choice for coastal buildings, industrial structures, and other applications where exposure to moisture and salt air is a concern. The panels maintain their appearance and structural integrity over time, reducing maintenance costs and preserving the building's aesthetic appeal for years to come.

Eco-Friendly Architecture: Sustainable Building Solutions

In an era where sustainability is increasingly important, aluminum foam sandwich panels offer a greener alternative to traditional building materials. The aluminum used in these panels is often recyclable, and their energy-efficient properties contribute to reduced carbon footprints for buildings.

Moreover, the lightweight nature of these panels can lead to reduced transportation costs and easier installation, further minimizing their environmental impact. For architects and builders committed to sustainable design practices, aluminum foam sandwich panels represent a step towards more eco-conscious construction.

Practical Applications: Where Aluminum Foam Panels Shine?

The versatility of aluminum foam sandwich panels makes them suitable for a wide range of architectural applications. Their unique combination of strength, insulation, and design flexibility has led to their adoption in various building types.

In commercial architecture, these panels are transforming office buildings, shopping centers, and hotels. Their sleek appearance and energy-efficient properties make them an attractive option for modern, sustainable commercial spaces. The panels' customizable nature allows for brand integration and unique facade designs that help businesses stand out.

Residential Innovations: Elevating Home Design

In the residential sector, aluminum foam sandwich panels are redefining what's possible at home design. From contemporary urban apartments to luxurious villas, these panels offer homeowners a combination of style and performance.

The panels' excellent insulation properties contribute to more comfortable living spaces and reduced energy bills. Their durability and low maintenance requirements make them an attractive option for homeowners looking for long-term value. Whether used for exterior cladding or interior wall decorations, these panels add a touch of sophistication to any home.

Institutional Excellence: Schools, Hospitals, and Beyond

Aluminum foam sandwich panels are also making waves in institutional architecture. Schools, hospitals, and government buildings benefit from the panels' durability, fire resistance, and energy efficiency. In educational settings, the panels contribute to creating safe, comfortable learning environments. For healthcare facilities, the panels' hygienic properties and ease of maintenance make them an excellent choice.

The adaptability of these panels allows architects to design institutional buildings that are both functional and aesthetically pleasing. From sleek, modern school buildings to state-of-the-art medical facilities, aluminum foam sandwich panels are helping to shape the future of institutional architecture.

Conclusion

Aluminum foam sandwich panels are more than just a building material; they're a catalyst for architectural innovation. Their unique combination of strength, insulation, design flexibility, and sustainability are enabling architects to push the boundaries of what's possible in building design.

As we look to the future of architecture, it's clear that materials like aluminum foam sandwich panels will play a crucial role in creating buildings that are not only visually stunning but also energy-efficient, safe, and sustainable. For those seeking to elevate their architectural projects with cutting-edge materials, aluminum foam sandwich panels offer a world of possibilities.

To learn more about how aluminum foam sandwich panels can transform your next architectural project, contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com. Our team of experts is ready to help you explore the potential of this innovative building material and bring your architectural vision to life.