Understanding Fibreglass Sandwich Panels

What are Fibreglass Sandwich Panels?

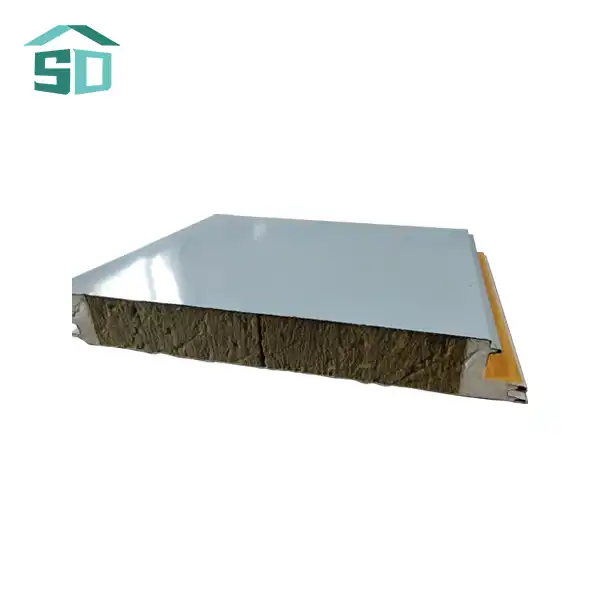

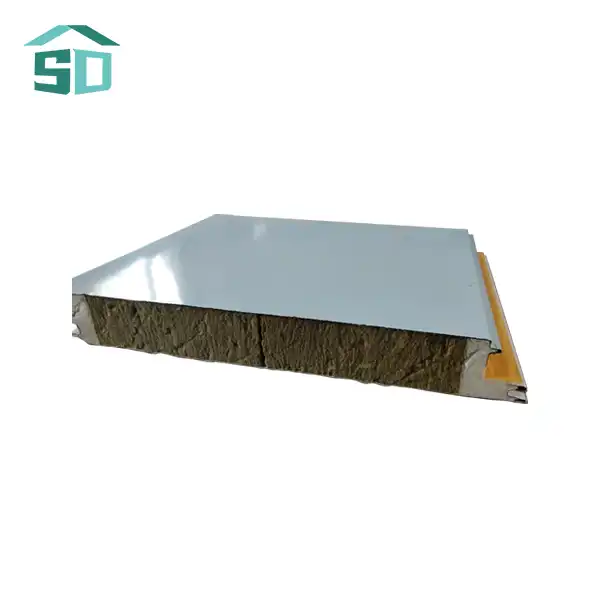

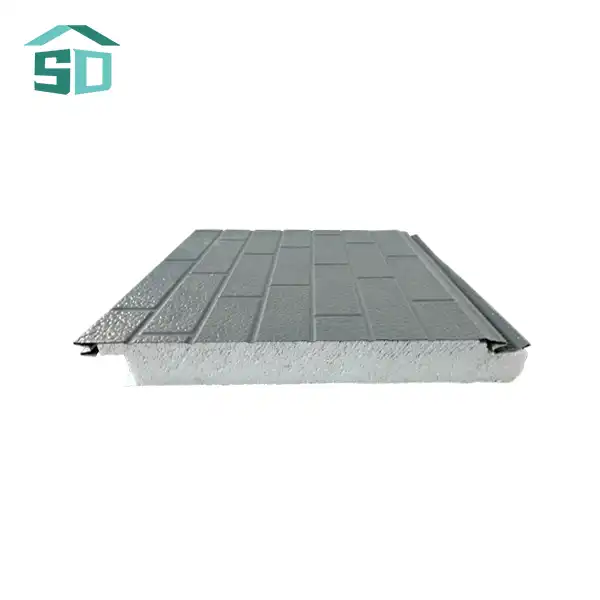

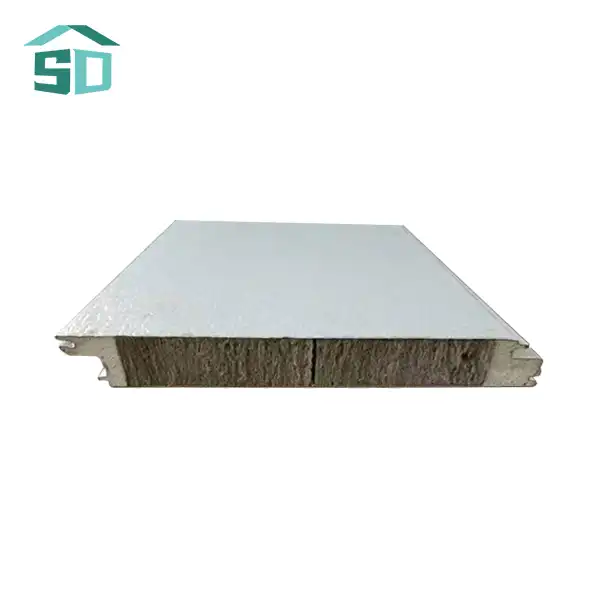

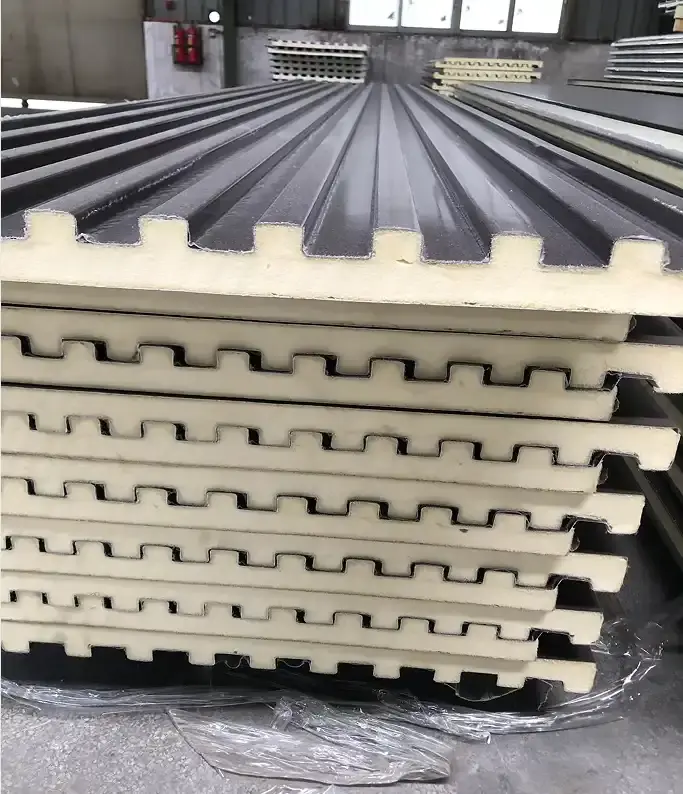

Fibreglass sandwich panels are composite materials consisting of two thin, rigid faces bonded to a lightweight core. The faces are typically made of fibreglass reinforced plastic (FRP), while the core is often composed of insulating materials such as polyurethane foam or polystyrene. These panels offer a unique combination of strength, durability, and insulation properties, making them ideal for various construction applications.

The structure of fibreglass sandwich panels allows for excellent thermal insulation, sound dampening, and moisture resistance. The fibreglass faces provide a smooth, durable surface that can be customized with different colors and finishes to suit architectural requirements. The core material contributes to the panel's lightweight nature while offering substantial structural support and insulation capabilities.

Benefits of Using Fibreglass Sandwich Panels

Fibreglass sandwich panels offer numerous advantages for construction projects:

- Exceptional Insulation: The core material provides superior thermal insulation, reducing energy costs for heating and cooling.

- Lightweight: Despite their strength, these panels are significantly lighter than traditional building materials, facilitating easier handling and installation.

- Durability: Fibreglass faces resist corrosion, weathering, and impacts, ensuring long-lasting performance.

- Moisture Resistance: The panels' composition helps prevent water ingress, reducing the risk of mold and structural damage.

- Versatility: Suitable for various applications, including walls, roofs, and partitions in residential, commercial, and industrial buildings.

- Low Maintenance: The smooth, non-porous surface is easy to clean and requires minimal upkeep.

- Customization: Available in various colors and finishes to meet specific aesthetic requirements.

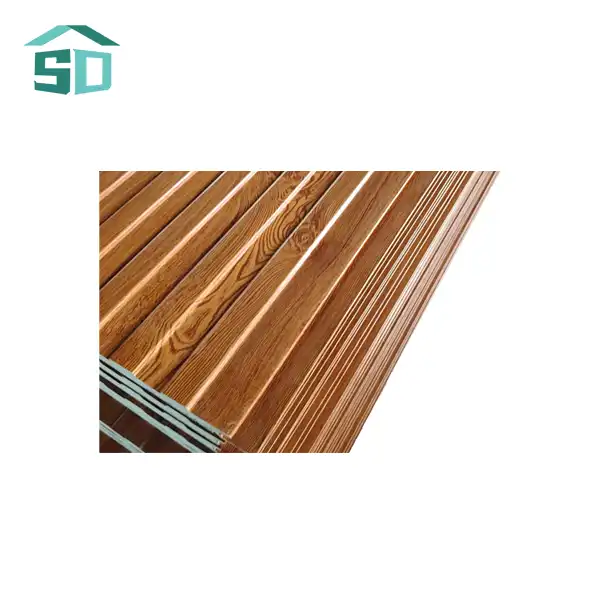

Types of Fibreglass Sandwich Panels

Fibreglass sandwich panels come in several variations to suit different construction needs:

- Standard Insulated Panels: These panels feature a uniform core thickness and are suitable for general wall and roof applications.

- Tapered Panels: Designed with a sloped core to facilitate water drainage on roofs.

- Fire-Rated Panels: Incorporate fire-resistant materials in the core to meet specific building code requirements.

- Structural Panels: Engineered to provide additional load-bearing capacity for demanding applications.

- Acoustical Panels: Feature perforated faces or specialized core materials to enhance sound absorption properties.

- Translucent Panels: Incorporate light-transmitting materials to allow natural illumination while maintaining insulation properties.

Understanding these variations helps in selecting the most appropriate fibreglass sandwich panels for your specific project requirements.

Preparation for Installation

Tools and Materials Needed

Proper preparation is crucial for a successful fibreglass sandwich panel installation. Gather the following tools and materials:

- Measuring tape

- Circular saw with fine-toothed blade

- Drill with appropriate bits

- Level

- Screwdriver

- Utility knife

- Safety equipment (goggles, gloves, dust mask)

- Adhesive suitable for fibreglass panels

- Fasteners (screws or rivets)

- Sealant for joints and edges

- Cleaning supplies

- Scaffolding or ladder (for elevated installations)

Having these items ready before beginning the installation process will ensure efficiency and minimize interruptions.

Site Preparation

Preparing the installation site is a critical step in ensuring the longevity and performance of your fibreglass sandwich panels. Follow these steps:

- Clear the Area: Remove any obstacles or debris from the installation site.

- Inspect the Substrate: Examine the surface where the panels will be installed. Ensure it's clean, dry, and free of any protruding nails or screws.

- Level the Surface: Use a level to check for any unevenness in the substrate. Address any significant irregularities to ensure a smooth installation.

- Apply Waterproofing: If installing on exterior walls or roofs, apply an appropriate waterproofing membrane to the substrate.

- Mark Guidelines: Use a chalk line to mark installation guidelines, ensuring proper alignment of the panels.

- Prepare Openings: If installing around windows or doors, ensure these openings are properly framed and sealed.

Taking the time to properly prepare the site will contribute to a more efficient installation process and better long-term performance of the fibreglass sandwich panels.

Safety Considerations

Safety should be a top priority when working with fibreglass sandwich panels. Consider the following precautions:

- Personal Protective Equipment (PPE): Wear safety goggles, gloves, and a dust mask to protect against fiberglass particles and dust.

- Proper Lifting Techniques: Use correct lifting methods to avoid strain or injury when handling panels.

- Secure Work Area: Ensure the installation area is clear of tripping hazards and properly cordoned off if working at heights.

- Tool Safety: Familiarize yourself with all tools and use them according to manufacturer instructions.

- Ventilation: When cutting panels or using adhesives, work in a well-ventilated area to avoid inhaling fumes.

- Electrical Safety: Be aware of any electrical wiring in the installation area to prevent accidental contact.

- Fall Protection: Use appropriate fall protection equipment when working at heights.

By adhering to these safety considerations, you can minimize the risk of accidents and ensure a smooth installation process for your fibreglass sandwich panels.

Installation Process

Step 1: Measuring and Cutting Panels

Accurate measurements and precise cutting are essential for a professional installation of fibreglass sandwich panels. Follow these steps:

- Measure the Installation Area: Use a measuring tape to determine the exact dimensions of the area where the panels will be installed.

- Plan Panel Layout: Sketch a layout plan, considering panel sizes and any openings for windows or doors. Aim to minimize the number of cuts and joints.

- Mark Cutting Lines: Transfer your measurements to the panels, clearly marking where cuts need to be made.

- Set Up Cutting Area: Create a stable work surface and ensure proper ventilation for cutting.

- Cut Panels: Using a circular saw with a fine-toothed blade, carefully cut along the marked lines. Maintain a steady hand to ensure straight, clean cuts.

- Sand Edges: Lightly sand the cut edges to remove any roughness or splinters.

Remember to wear appropriate safety gear, including goggles and a dust mask, when cutting fibreglass sandwich panels.

Step 2: Applying Adhesive

Proper adhesive application is crucial for securing fibreglass sandwich panels:

- Choose the Right Adhesive: Select an adhesive specifically designed for fibreglass panels and compatible with your substrate material.

- Prepare the Surface: Ensure the substrate is clean, dry, and free of dust or debris.

- Apply Adhesive: Using a notched trowel or as per manufacturer instructions, apply the adhesive evenly to the substrate or panel back.

- Coverage: Ensure complete coverage, paying special attention to edges and corners.

- Follow Curing Time: Allow the adhesive to become tacky before placing the panel, following the manufacturer's recommended curing time.

Proper adhesive application helps ensure a strong, long-lasting bond between the fibreglass sandwich panels and the substrate.

Step 3: Positioning and Securing Panels

Careful positioning and secure fastening are key to a successful installation:

- Align the First Panel: Position the first panel according to your layout plan, ensuring it's level and plumb.

- Apply Pressure: Once in position, apply even pressure across the panel to ensure good contact with the adhesive.

- Secure with Fasteners: Use appropriate screws or rivets to secure the panel. Follow the manufacturer's recommendations for fastener type and spacing.

- Continue Installation: Proceed with subsequent panels, maintaining proper alignment and leaving recommended gaps for expansion.

- Cut for Openings: When you reach windows or doors, carefully cut the panels to fit around these openings.

- Check Alignment: Periodically check that panels remain level and aligned as you progress.

Take your time with this step to ensure each fibreglass sandwich panel is correctly positioned and securely fastened.

Step 4: Sealing Joints and Edges

Proper sealing is crucial for preventing moisture intrusion and ensuring the longevity of your installation:

- Clean Joints: Ensure all joints and edges are clean and dry before sealing.

- Apply Sealant: Use a high-quality, flexible sealant compatible with fibreglass panels. Apply it evenly along all joints and edges.

- Tool the Sealant: Use a putty knife or specialized tool to smooth the sealant, ensuring complete coverage and a neat appearance.

- Seal Penetrations: Pay special attention to areas around fasteners, windows, and doors, ensuring thorough sealing.

- Allow Curing: Let the sealant cure completely as per manufacturer instructions before exposing it to moisture or stress.

Proper sealing not only enhances the appearance of your fibreglass sandwich panel installation but also significantly contributes to its weather resistance and durability.

Conclusion

Installing fibreglass sandwich panels is a rewarding process that can significantly enhance the energy efficiency, durability, and aesthetics of your building. By following this step-by-step guide, you can ensure a professional and long-lasting installation. Remember to prioritize safety, take accurate measurements, and pay attention to detail throughout the process. The versatility and benefits of fibreglass sandwich panels make them an excellent choice for various construction applications, from residential to commercial projects. Their lightweight nature, superior insulation properties, and durability offer substantial advantages over traditional building materials.

For those seeking high-quality fibreglass sandwich panels and expert guidance, Weifang Sandong Building Materials Co., Ltd. is your trusted partner. Our extensive range of exterior cladding and facade solutions, including top-tier fibreglass sandwich panels for sale, can meet the diverse needs of your construction projects. To learn more about our products or to discuss your specific requirements, please don't hesitate to contact us at info@sdqsc.com.

FAQ

Can fibreglass sandwich panels be used for both interior and exterior applications?

Yes, fibreglass sandwich panels are versatile and can be used for both interior and exterior applications. Their durability, insulation properties, and moisture resistance make them suitable for various environments.

How long do fibreglass sandwich panels typically last?

With proper installation and maintenance, fibreglass sandwich panels can last 25-30 years or more, depending on the specific product and environmental conditions.

Are fibreglass sandwich panels environmentally friendly?

Many fibreglass sandwich panels are designed with sustainability in mind, offering excellent insulation that can reduce energy consumption. Some manufacturers also use recycled materials in their production process.

References

1. Building Science Corporation. (2021). "Insulation Materials and Their Properties."

2. American Composites Manufacturers Association. (2022). "Fiberglass Composite Design Guide."

3. U.S. Department of Energy. (2023). "Insulation Materials."

4. International Code Council. (2021). "International Building Code."

5. National Institute of Building Sciences. (2022). "Whole Building Design Guide - Building Envelope."