- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How do insulated wall panels compare to traditional construction methods?

Insulated wall panels offer significant advantages over traditional construction methods, revolutionizing the building industry. These innovative panels provide superior energy efficiency, faster installation times, and enhanced durability compared to conventional brick-and-mortar or wood-frame construction. By combining structural support, insulation, and exterior finishing in one prefabricated unit, insulated wall panels streamline the building process while delivering excellent thermal performance. This results in reduced energy costs, improved indoor comfort, and a smaller environmental footprint. As the construction industry evolves, insulated wall panels are emerging as a game-changing solution that addresses many of the limitations of traditional building techniques.

Energy Efficiency and Thermal Performance

Superior Insulation Properties of Insulated Wall Panels

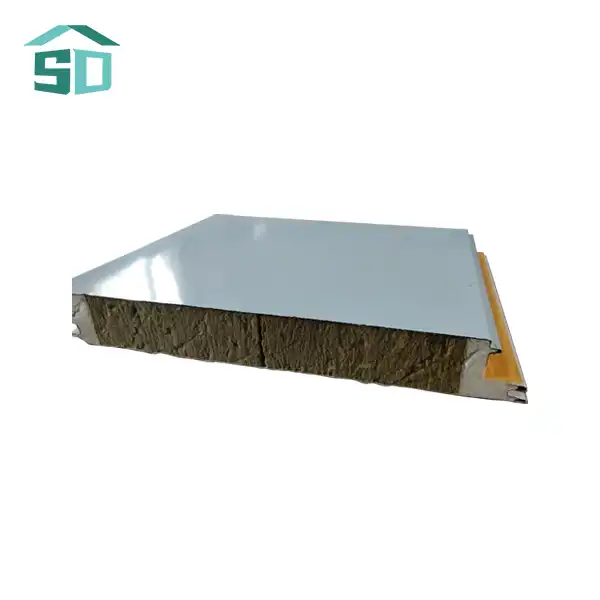

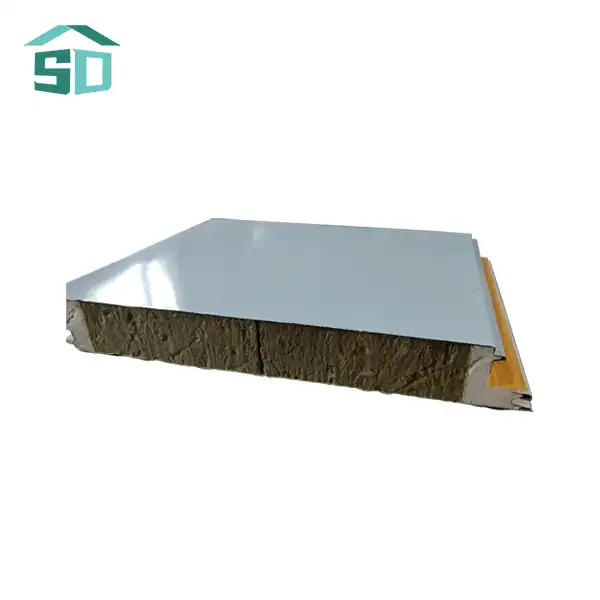

Insulated wall panels excel in thermal performance, offering significantly better insulation than traditional construction methods. The core of these panels typically consists of high-performance materials like polyurethane, polystyrene, or mineral wool, which provide exceptional R-values. This enhanced insulation capability translates to reduced heat transfer, maintaining consistent indoor temperatures and minimizing energy consumption for heating and cooling. In contrast, conventional walls often struggle with thermal bridging and inconsistent insulation, leading to energy loss and higher utility bills.

Airtight Construction for Improved Energy Conservation

One of the key advantages of insulated wall panels is their ability to create an airtight building envelope. The seamless integration of these panels eliminates many of the gaps and cracks common in traditional construction, which can account for significant heat loss. This airtight seal not only improves energy efficiency but also enhances indoor air quality by reducing the infiltration of outdoor pollutants and allergens. Insulated wall panels manufacturers often incorporate advanced sealing technologies to ensure optimal performance in this regard.

Long-Term Cost Savings Through Reduced Energy Consumption

While the initial investment in insulated wall panels may be higher than some traditional methods, the long-term cost savings are substantial. The superior insulation properties and airtight construction lead to dramatically reduced energy consumption over the life of the building. This translates to lower heating and cooling costs, with some studies showing energy savings of up to 50% compared to conventional construction. As energy prices continue to rise, the financial benefits of using insulated wall panels become increasingly apparent.

Construction Speed and Efficiency

Rapid Installation of Insulated Wall Panels

One of the most significant advantages of insulated wall panels over traditional construction methods is the speed of installation. These prefabricated panels arrive on-site ready to be installed, dramatically reducing construction time. A skilled crew can often install insulated wall panels for an entire building in a matter of days, compared to weeks or months for traditional brick or wood-frame construction. This rapid installation not only accelerates project timelines but also reduces labor costs and minimizes disruption to surrounding areas.

Reduced On-Site Labor and Skilled Trade Requirements

The use of insulated wall panels simplifies the construction process, reducing the need for multiple specialized trades on-site. Traditional methods often require separate teams for framing, insulation, vapor barriers, and exterior finishing. In contrast, insulated wall panels integrate all these components into a single unit, streamlining the installation process. This reduction in on-site labor not only speeds up construction but also helps mitigate the challenges posed by skilled labor shortages in the construction industry.

Weather-Independent Construction Progress

Insulated wall panels offer a significant advantage in terms of weather-independent construction. Unlike traditional methods that can be severely impacted by adverse weather conditions, the installation of these panels can proceed in a wider range of weather scenarios. This is particularly beneficial in regions with short construction seasons or unpredictable weather patterns. The ability to continue work in less-than-ideal conditions helps keep projects on schedule and reduces costly delays.

Durability and Sustainability

Enhanced Structural Integrity of Insulated Wall Panels

Insulated wall panels are engineered for superior structural integrity compared to many traditional construction methods. The composite nature of these panels, often combining strong exterior facings with a rigid insulation core, results in a lightweight yet extremely durable building envelope. This enhanced strength can improve a building's resistance to wind loads, seismic activity, and other environmental stresses. Many insulated wall panels manufacturers design their products to meet or exceed stringent building codes and standards for structural performance.

Resistance to Moisture and Mold Growth

One of the critical advantages of insulated wall panels is their excellent resistance to moisture infiltration and mold growth. The seamless nature of these panels, combined with advanced moisture barriers, creates a highly effective defense against water intrusion. This is in stark contrast to traditional construction methods, which can be prone to moisture-related issues if not executed perfectly. The reduced risk of mold and moisture damage not only enhances the longevity of the building but also contributes to healthier indoor environments for occupants.

Environmental Benefits and Recyclability

Insulated wall panels offer several environmental benefits over traditional construction methods. The precision manufacturing process results in minimal on-site waste, reducing the environmental impact of construction. Many insulated wall panels are made with recyclable materials and can be recycled at the end of their life cycle, contributing to a circular economy in construction. Additionally, the superior energy efficiency of buildings constructed with these panels leads to reduced carbon emissions over the building's lifetime. As sustainability becomes increasingly important in construction, the eco-friendly aspects of insulated wall panels make them an attractive option for environmentally conscious projects.

Conclusion

Insulated wall panels represent a significant advancement over traditional construction methods, offering a compelling combination of energy efficiency, rapid installation, and enhanced durability. Their superior thermal performance and airtight construction lead to substantial energy savings and improved indoor comfort. The speed and simplicity of installation reduce project timelines and labor costs, while their structural integrity and moisture resistance contribute to long-lasting, low-maintenance buildings. As the construction industry continues to evolve towards more sustainable and efficient practices, insulated wall panels are poised to play an increasingly important role in shaping the future of building design and construction.

Ready to experience the benefits of insulated wall panels for your next project? Contact Weifang Sandong Building Materials Co., Ltd. at info@sdqsc.com to learn more about our innovative insulated wall panel solutions. Our team of experts is here to help you choose the perfect panels for your specific needs, ensuring optimal performance, energy efficiency, and aesthetic appeal for your building. Don't settle for outdated construction methods – embrace the future of building technology with our state-of-the-art insulated wall panels.

FAQ

How do insulated wall panels compare in cost to traditional construction methods?

While the initial cost of insulated wall panels may be higher, they often result in significant long-term savings through reduced energy costs and faster construction times.

Are insulated wall panels suitable for all climate types?

Yes, insulated wall panels can be customized for various climate zones, offering excellent performance in both hot and cold environments.

How long do insulated wall panels typically last?

With proper installation and maintenance, insulated wall panels can last for several decades, often outlasting traditional construction materials.

Can insulated wall panels be used for both residential and commercial buildings?

Absolutely. Insulated wall panels are versatile and can be used in a wide range of building types, from homes to large commercial structures.

References

1.U.S. Department of Energy. (2022). "Insulation Materials." Energy Saver.

2.International Code Council. (2021). "International Energy Conservation Code."

3.National Institute of Building Sciences. (2020). "Whole Building Design Guide: Building Envelope."

4.American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2019). "ASHRAE Handbook—Fundamentals."

5.U.S. Green Building Council. (2023). "LEED rating system."