Introducing PU Insulation Boards: Composition and Properties

The Science Behind PU Insulation Boards

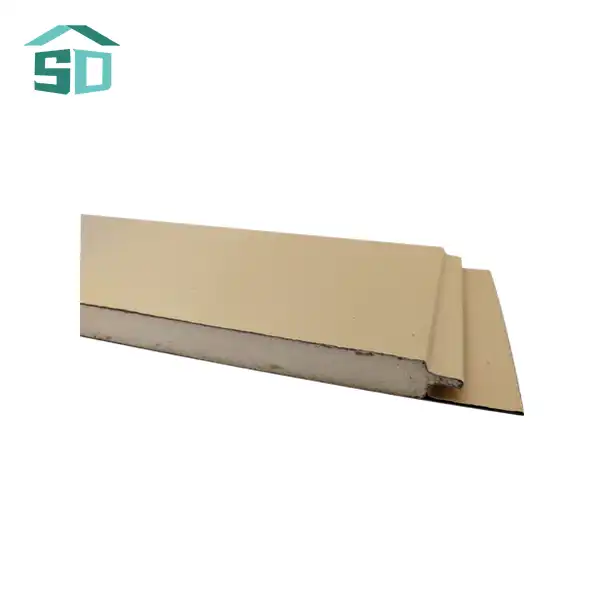

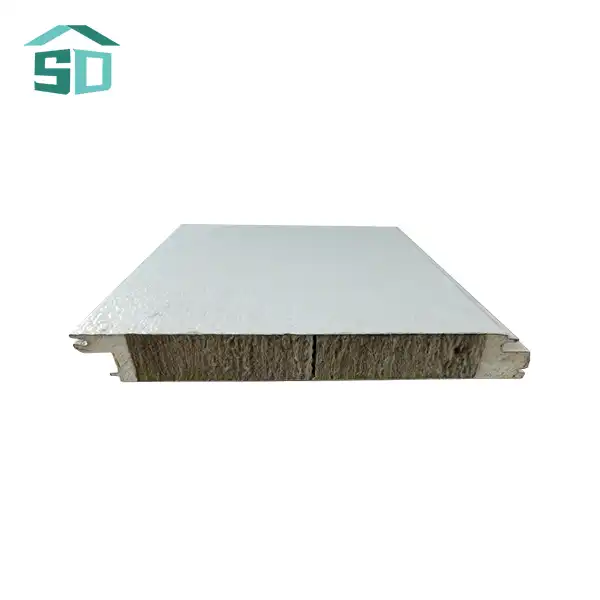

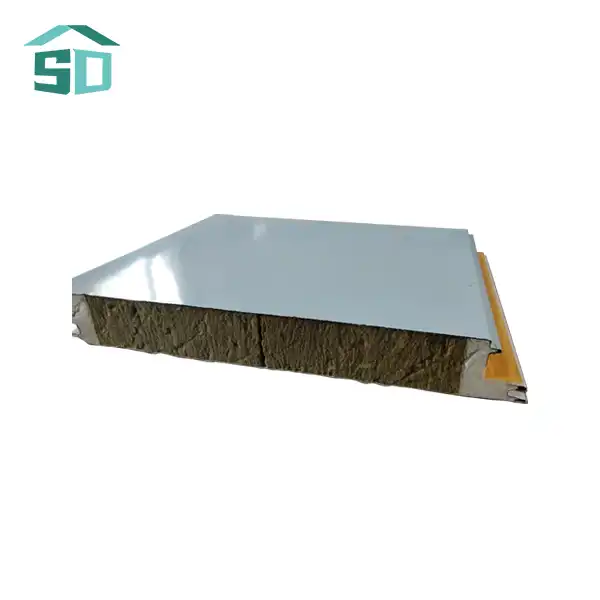

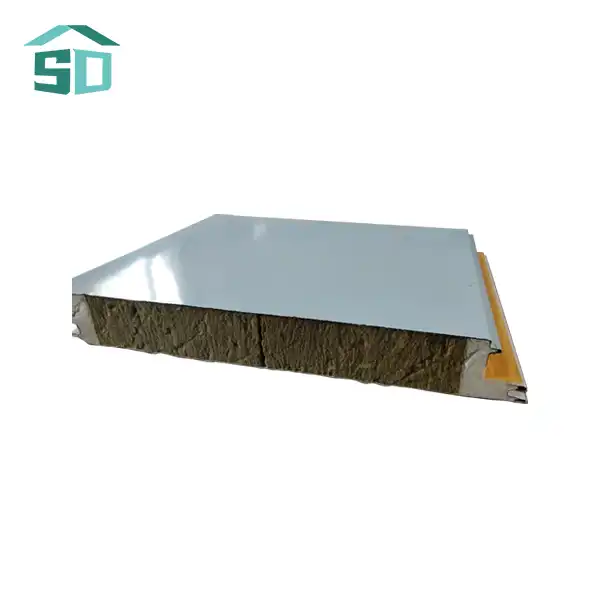

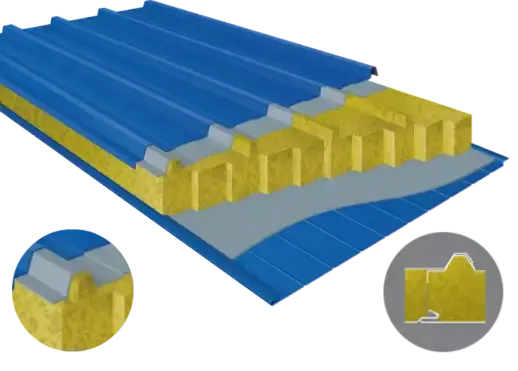

PU insulation boards, short for polyurethane insulation boards, are high-performance materials engineered to provide superior thermal insulation. These boards are composed of a rigid polyurethane foam core, which is created through a chemical reaction between polyol and isocyanate. This reaction produces a closed-cell structure that traps low conductivity gases within its matrix, resulting in exceptional insulating properties.

The unique composition of PU insulation boards allows them to achieve thermal conductivity values as low as 0.022 W/m·K, significantly outperforming traditional insulation materials. This remarkable efficiency means that thinner layers of PU insulation can provide the same level of insulation as thicker layers of conventional materials, leading to space savings and increased design flexibility in construction projects.

Key Properties of PU Insulation Boards

PU insulation boards boast an impressive array of properties that make them ideal for various applications:

- Thermal Efficiency: As mentioned, PU insulation boards offer superior thermal performance, reducing heat transfer and improving energy efficiency in buildings.

- Moisture Resistance: The closed-cell structure of PU insulation boards provides excellent resistance to moisture penetration, helping to prevent mold growth and maintain insulation effectiveness over time.

- Dimensional Stability: PU insulation boards maintain their shape and size even under varying temperature and humidity conditions, ensuring long-term performance.

- Lightweight: Despite their robust insulation capabilities, PU insulation boards are remarkably lightweight, making them easy to handle and install.

- Durability: These boards are known for their long lifespan, often outlasting the buildings they're installed in when properly maintained.

Understanding these properties is crucial for anyone considering PU insulation boards for their construction or renovation projects. The combination of these characteristics makes PU insulation boards a versatile solution for a wide range of applications, from residential homes to commercial buildings and industrial facilities.

Fire Safety Features of PU Insulation Boards

Advanced Fire Retardant Technologies

When it comes to building materials, fire safety is paramount. PU insulation boards have made significant strides in this area, incorporating advanced fire retardant technologies to enhance their safety profile. Modern PU insulation boards are engineered with fire-resistant additives that are integrated into the foam matrix during the manufacturing process. These additives work to inhibit ignition and slow down flame spread in the event of a fire.

One of the key advancements in PU insulation board fire safety is the development of intumescent coatings. When exposed to high temperatures, these coatings expand and form a protective char layer, which acts as a barrier to heat and flames. This innovative approach significantly improves the fire performance of PU insulation boards, making them a safer choice for building applications.

Fire Performance Testing and Ratings

PU insulation boards undergo rigorous fire performance testing to ensure they meet or exceed industry standards. These tests evaluate various aspects of fire behavior, including:

- Flame Spread: Measures how quickly flames travel across the surface of the material.

- Smoke Development: Assesses the amount and density of smoke produced during combustion.

- Heat Release Rate: Determines the rate at which heat is generated during burning.

- Self-Extinguishing Properties: Evaluates the material's ability to stop burning once the ignition source is removed.

Based on these tests, PU insulation boards are assigned fire ratings that indicate their level of fire resistance. Many PU insulation boards achieve a Class B1 fire rating, which signifies that they are "non-combustible" or have very low combustibility. This rating is crucial for meeting building code requirements and ensuring the safety of occupants in the event of a fire.

It's important to note that while PU insulation boards have made significant advancements in fire safety, proper installation and adherence to building codes are essential for maximizing their fire-resistant properties. When selecting PU insulation boards for a project, always consult with a reputable PU insulation board factory to ensure you're choosing products that meet the specific fire safety requirements of your application.

Balancing Thermal Performance and Fire Safety in Construction

Optimizing Insulation Thickness for Energy Efficiency

One of the key challenges in modern construction is finding the right balance between thermal performance and fire safety. PU insulation boards excel in this area by offering superior insulation properties with relatively thin layers. This allows architects and builders to achieve high energy efficiency standards without compromising on fire safety or sacrificing valuable floor space.

When determining the optimal thickness of PU insulation boards for a project, several factors come into play:

- Climate Zone: The local climate significantly influences the required insulation levels.

- Building Type: Different structures (e.g., residential, commercial, industrial) have varying insulation needs.

- Energy Efficiency Goals: The desired level of energy performance impacts insulation thickness.

- Building Codes: Local regulations often specify minimum insulation requirements.

By carefully considering these factors, construction professionals can determine the ideal thickness of PU insulation boards to achieve optimal thermal performance while adhering to fire safety standards. The high thermal efficiency of PU insulation boards often allows for thinner installations compared to traditional materials, providing more design flexibility and potential cost savings.

Integrating PU Insulation Boards with Fire Safety Systems

To maximize both thermal performance and fire safety, it's crucial to integrate PU insulation boards with other fire safety systems in a building. This holistic approach ensures comprehensive protection while maintaining energy efficiency. Some key integration strategies include:

- Fire Barriers: Installing fire-resistant barriers at regular intervals within the insulation layer to compartmentalize potential fire spread.

- Fireproof Coatings: Applying additional fireproof coatings to PU insulation boards in high-risk areas for enhanced protection.

- Cavity Barriers: Implementing cavity barriers in conjunction with PU insulation boards to prevent fire from spreading through hidden spaces.

- Smoke Detection Systems: Ensuring that smoke detectors are properly placed and not obstructed by insulation materials.

- Sprinkler Systems: Coordinating the installation of PU insulation boards with sprinkler system layouts for optimal fire suppression.

By thoughtfully integrating PU insulation boards with these fire safety measures, builders can create structures that are both energy-efficient and fire-resistant. This integrated approach not only enhances safety but also contributes to the overall performance and longevity of the building.

It's worth noting that the specific integration strategies may vary depending on the building type, local regulations, and project requirements. Consulting with fire safety experts and experienced PU insulation board manufacturers is essential to develop a comprehensive fire safety plan that leverages the benefits of PU insulation boards while meeting all necessary safety standards.

Conclusion

PU insulation boards have revolutionized the construction industry by offering an exceptional balance between thermal performance and fire safety. Their unique properties, including superior insulation capabilities, moisture resistance, and fire-retardant features, make them an ideal choice for a wide range of building applications. By optimizing insulation thickness and integrating PU insulation boards with comprehensive fire safety systems, construction professionals can create structures that are not only energy-efficient but also safer for occupants.

Are you ready to enhance your next construction project with high-quality PU insulation boards? At Weifang Sandong Building Materials Co., Ltd., we specialize in manufacturing premium PU insulation boards that meet the highest standards of thermal performance and fire safety. Our expert team is here to help you find the perfect solution for your specific needs. Contact us today at info@sdqsc.com to learn more about our products and how we can contribute to the success of your building projects.

FAQ

What makes PU insulation boards different from traditional insulation materials?

PU insulation boards offer superior thermal performance, moisture resistance, and fire safety features in a thinner profile compared to traditional materials.

Are PU insulation boards environmentally friendly?

Many modern PU insulation boards are produced with eco-friendly formulations and can contribute to energy efficiency in buildings, reducing overall environmental impact.

How long do PU insulation boards typically last?

When properly installed and maintained, PU insulation boards can last for the lifetime of the building, often 50 years or more.

Can PU insulation boards be used in both new construction and renovation projects?

Yes, PU insulation boards are versatile and can be effectively used in both new construction and renovation projects across various building types.

References

1. Building Science Corporation. (2021). "High Performance Building Enclosures: Polyurethane Insulation."

2. National Institute of Standards and Technology. (2020). "Fire Performance of Polyurethane Foam Insulation."

3. International Code Council. (2021). "International Building Code."

4. U.S. Department of Energy. (2022). "Insulation Materials."

5. European Association for Passive Fire Protection. (2021). "Fire Safety Engineering Guidelines."