- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

PU Insulated Sandwich Panels: Enhance Thermal Comfort

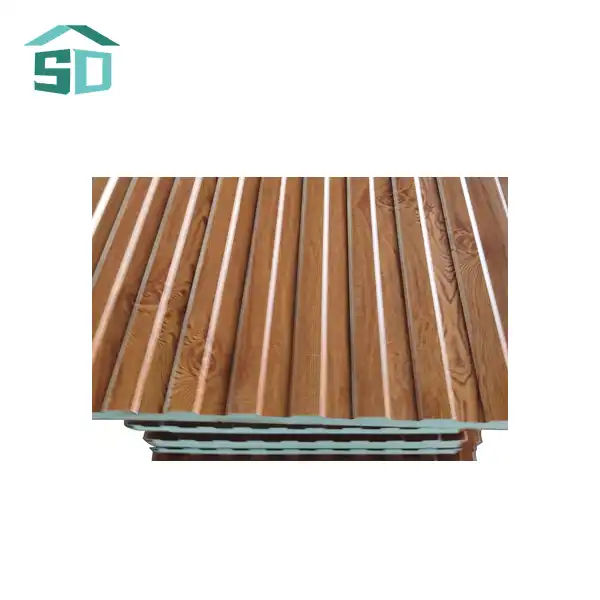

PU Insulated Sandwich Panels are revolutionizing the construction industry by offering unparalleled thermal comfort and energy efficiency. These innovative panels consist of a polyurethane (PU) foam core sandwiched between two layers of durable materials, typically steel or aluminum. The unique composition of these panels provides excellent insulation properties, effectively regulating indoor temperatures and reducing energy consumption. By creating a robust thermal barrier, PU Insulated Sandwich Panels help maintain comfortable living and working environments while minimizing heating and cooling costs. Their versatility, durability, and superior insulation make them an ideal choice for various applications, from residential buildings to commercial structures.

The Science Behind PU Insulated Sandwich Panels

Composition and Structure

PU Insulated Sandwich Panels are engineered to maximize thermal performance through their innovative design. The core of these panels is made from polyurethane foam, a material renowned for its exceptional insulating properties. This foam is sandwiched between two layers of high-quality materials, often steel or aluminum, creating a robust and efficient insulation system.

The polyurethane foam used in these panels is a closed-cell structure, which means it contains millions of tiny air pockets. These air pockets act as barriers to heat transfer, effectively reducing thermal conductivity. The result is a panel that provides superior insulation compared to traditional building materials.

Thermal Resistance and R-Value

One of the key factors in assessing the insulation performance of PU Insulated Sandwich Panels is their R-value. The R-value is a measure of thermal resistance, indicating how well a material insulates. PU foam has an impressively high R-value per inch of thickness, making it one of the most efficient insulation materials available.

Typically, PU Insulated Sandwich Panels have R-values ranging from R-6 to R-8 per inch of thickness. This means that even relatively thin panels can provide significant insulation, allowing for space-saving designs without compromising on thermal performance. The high R-value of these panels contributes to their ability to enhance thermal comfort in various climates and building types.

Energy Efficiency and Cost Savings

The superior insulation properties of PU Insulated Sandwich Panels translate directly into energy efficiency and cost savings. By creating an effective thermal barrier, these panels reduce the amount of heat transfer between the interior and exterior of a building. This results in lower heating costs during winter and reduced cooling expenses in summer.

Studies have shown that buildings using PU Insulated Sandwich Panels can achieve energy savings of up to 30% compared to traditional construction methods. Over time, these savings can offset the initial investment in the panels, making them a cost-effective choice for long-term building performance.

Versatility and Applications of PU Insulated Sandwich Panels

Residential Construction

In residential construction, PU Insulated Sandwich Panels offer homeowners a way to create energy-efficient, comfortable living spaces. These panels can be used for exterior walls, roofs, and even interior partitions. Their excellent insulation properties help maintain consistent indoor temperatures, reducing the reliance on heating and cooling systems.

Moreover, the panels' durability and resistance to moisture make them ideal for areas prone to extreme weather conditions. They can withstand heavy rain, snow, and wind, providing long-lasting protection for homes. The panels' sleek appearance also contributes to modern architectural designs, enhancing the aesthetic appeal of residential properties.

Commercial and Industrial Buildings

PU Insulated Sandwich Panels find extensive use in commercial and industrial construction projects. Their ability to span large distances without intermediate supports makes them particularly suitable for warehouses, factories, and retail spaces. The panels' high load-bearing capacity allows for the creation of spacious interiors without compromising structural integrity.

In cold storage facilities and food processing plants, these panels play a crucial role in maintaining precise temperature control. Their excellent insulation properties help reduce energy consumption in these energy-intensive environments, contributing to significant cost savings and improved operational efficiency.

Agricultural Structures

The agricultural sector also benefits from the use of PU Insulated Sandwich Panels. These panels are ideal for constructing barns, storage facilities, and greenhouses. In livestock housing, the panels help maintain optimal temperatures for animal welfare, while in crop storage facilities, they prevent temperature fluctuations that could affect product quality.

The panels' resistance to moisture and chemicals makes them particularly suitable for agricultural applications, where exposure to harsh environmental conditions and cleaning agents is common. Their easy-to-clean surfaces also contribute to maintaining hygienic conditions in these sensitive environments.

Advanced Features and Benefits of PU Insulated Sandwich Panels

Fire Resistance and Safety

One of the most critical aspects of building materials is their fire resistance, and PU Insulated Sandwich Panels excel in this area. Modern PU foam formulations incorporate fire-retardant additives that significantly enhance the panels' fire resistance properties. These panels are designed to meet stringent fire safety standards, providing crucial time for evacuation in case of a fire.

The fire-resistant properties of these panels are typically classified according to international standards, such as EN 13501-1 in Europe or ASTM E84 in the United States. Many PU Insulated Sandwich Panels achieve high ratings in these tests, demonstrating their ability to resist flame spread and smoke development.

Acoustic Performance

Beyond thermal insulation, PU Insulated Sandwich Panels also offer excellent acoustic performance. The dense structure of the polyurethane foam core helps to absorb and dampen sound waves, reducing noise transmission between spaces. This feature is particularly valuable in commercial and industrial settings, where noise reduction can significantly improve working conditions.

The acoustic properties of these panels can be further enhanced through the use of perforated or textured surface finishes. These modifications can increase sound absorption, making PU Insulated Sandwich Panels an ideal choice for applications where noise control is a priority, such as in auditoriums, studios, or office spaces.

Customization and Aesthetics

PU Insulated Sandwich Panels offer a high degree of customization, allowing architects and designers to achieve both functional and aesthetic goals. These panels are available in a wide range of colors, textures, and finishes, enabling seamless integration with various architectural styles.

The outer layers of the panels can be manufactured using different materials and profiles, including smooth, ribbed, or embossed surfaces. This versatility allows for creative façade designs that can enhance the visual appeal of buildings while maintaining optimal insulation performance.

Conclusion

PU Insulated Sandwich Panels represent a significant advancement in building technology, offering a unique combination of thermal efficiency, versatility, and aesthetic appeal. Their ability to enhance thermal comfort while reducing energy consumption makes them an invaluable asset in modern construction. From residential homes to industrial facilities, these panels provide a sustainable and cost-effective solution for creating comfortable, energy-efficient spaces.

For those interested in learning more about PU Insulated Sandwich Panels and how they can enhance your building projects, we invite you to contact us at info@sdqsc.com. Our team of experts is ready to provide you with detailed information and guidance on incorporating these innovative panels into your next construction endeavor.

References

1. European Association for Panels and Profiles. (2021). "PU Sandwich Panels: Properties and Applications."

2. International Energy Agency. (2020). "Energy Efficiency in Buildings Report."

3. Fire Protection Research Foundation. (2019). "Fire Performance of Insulated Building Panels."

4. American Society for Testing and Materials. (2021). "ASTM E84 - Standard Test Method for Surface Burning Characteristics of Building Materials."

5. Journal of Building Engineering. (2022). "Acoustic Properties of Polyurethane Foam in Building Applications."