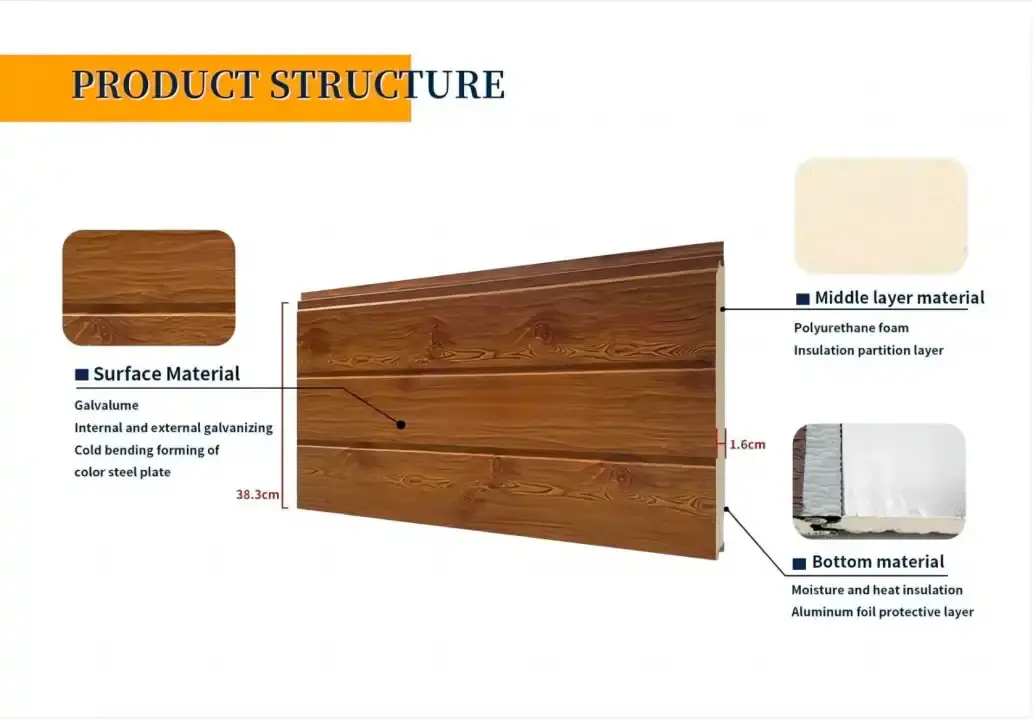

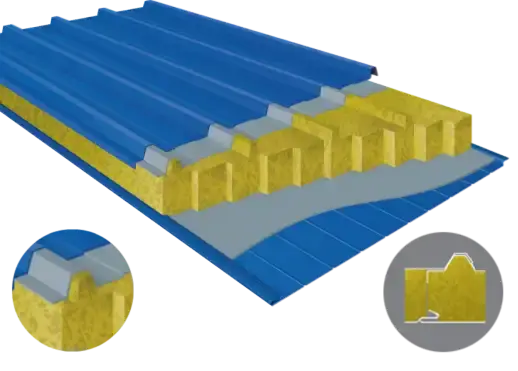

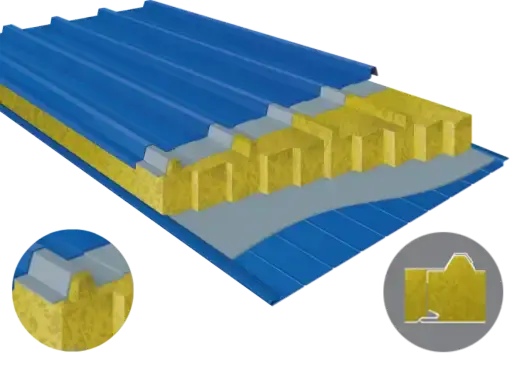

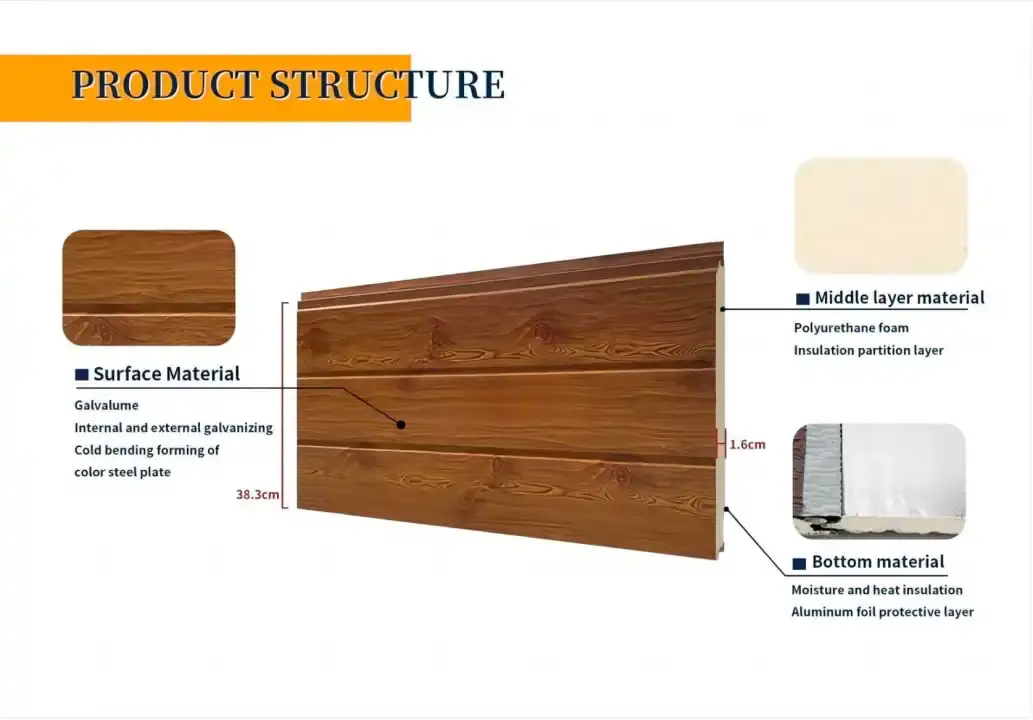

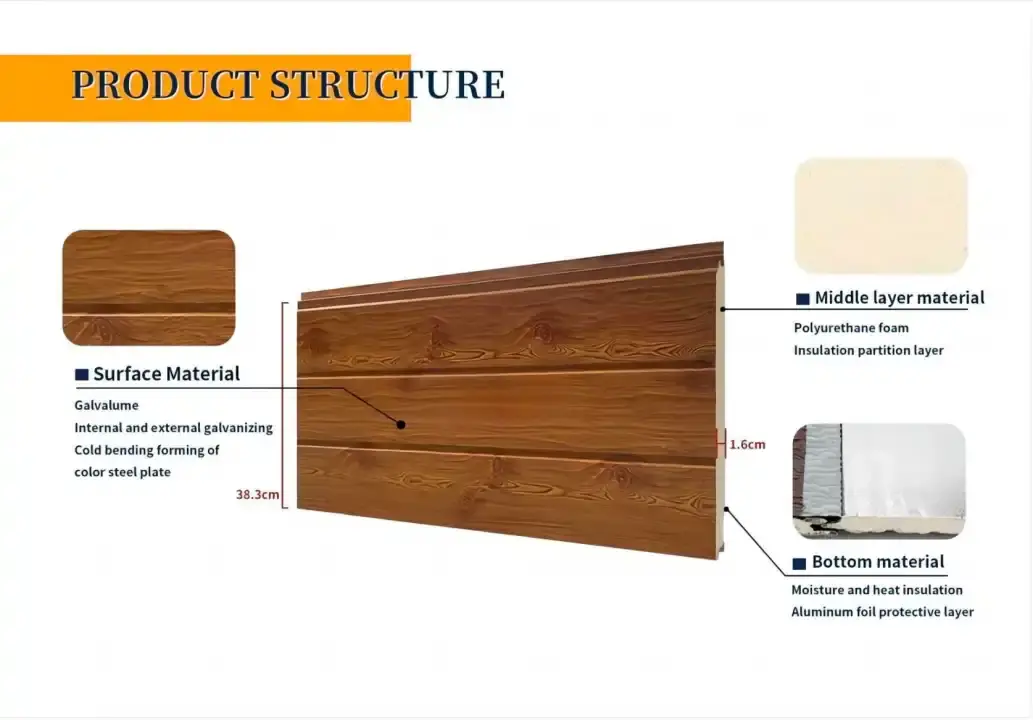

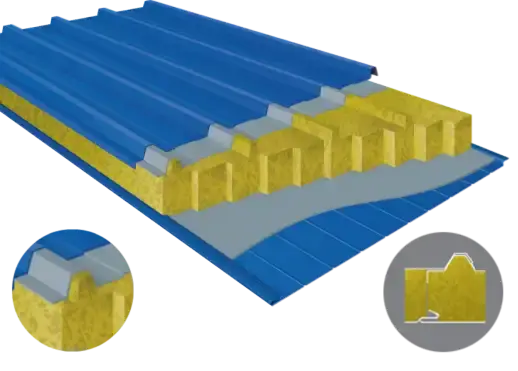

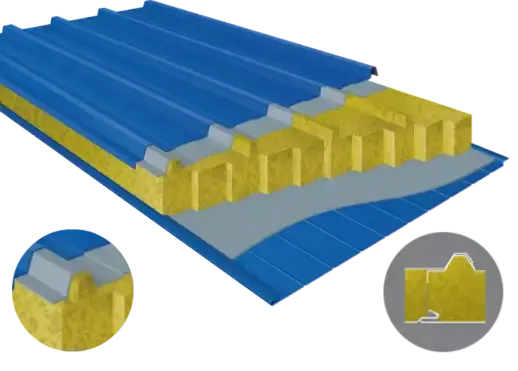

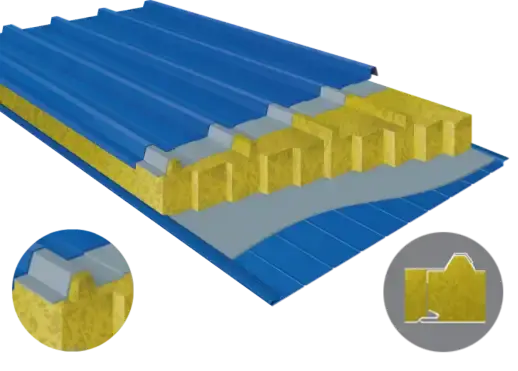

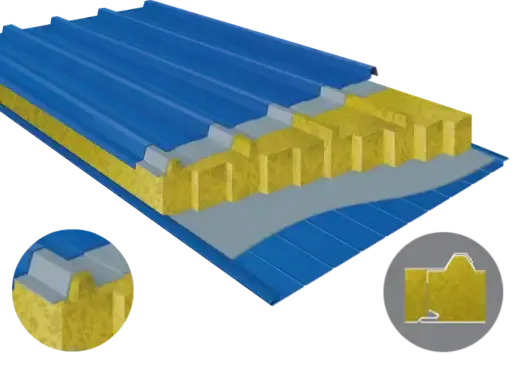

In the ever-evolving world of construction and cold storage, PUF sandwich panels have emerged as a game-changing solution. These innovative panels, composed of a polyurethane foam core sandwiched between two metal sheets, are transforming the way we approach temperature-controlled environments. As the demand for efficient and sustainable cold storage facilities continues to grow, PUF sandwich panels are stepping up to meet the challenge, offering a perfect blend of insulation, durability, and cost-effectiveness.

The Unparalleled Insulation Properties of PUF Sandwich Panels

At the heart of PUF sandwich panels' success in cold storage applications lies their exceptional insulation capabilities. The polyurethane foam core acts as a formidable barrier against heat transfer, ensuring that the desired temperature within the storage facility remains constant with minimal energy expenditure. This remarkable insulation performance is attributed to the closed-cell structure of the foam, which effectively traps air and prevents thermal bridging.

Superior Thermal Resistance

PUF sandwich panels boast an impressive R-value, a measure of thermal resistance, which far surpasses traditional insulation materials. This high R-value translates to significantly reduced heat gain or loss, allowing cold storage facilities to maintain precise temperature control with less strain on refrigeration systems. As a result, businesses can achieve substantial energy savings while ensuring the integrity of their stored goods.

Minimizing Thermal Fluctuations

In cold storage environments, even minor temperature fluctuations can have detrimental effects on perishable goods. PUF sandwich panels excel in mitigating these fluctuations by creating a highly stable thermal envelope. The uniform insulation provided by these panels helps to eliminate hot spots and cold zones, ensuring consistent temperature distribution throughout the storage space. This level of thermal stability is crucial for maintaining product quality and extending shelf life in cold storage applications.

Moisture Resistance and Vapor Barrier

Another critical aspect of cold storage insulation is moisture management. PUF sandwich panels offer excellent moisture resistance and act as an effective vapor barrier. The closed-cell structure of the polyurethane foam prevents water vapor from penetrating the insulation, reducing the risk of condensation and mold growth within the storage facility. This moisture-resistant property not only protects the stored goods but also helps maintain the structural integrity of the building over time.

Durability and Longevity: The Hallmarks of PUF Sandwich Panels

While insulation performance is paramount, the success of PUF sandwich panels in cold storage applications extends beyond their thermal properties. These panels are engineered to withstand the demanding conditions of cold storage environments, offering exceptional durability and longevity that contribute to their overall cost-effectiveness.

Resilience in Extreme Temperatures

PUF sandwich panels are designed to maintain their structural integrity and insulation properties across a wide range of temperatures. Whether subjected to sub-zero temperatures in freezer units or exposed to occasional temperature fluctuations, these panels remain stable and functional. This resilience ensures that cold storage facilities can operate reliably year-round, without compromising on energy efficiency or product safety.

Resistance to Corrosion and Chemical Exposure

In cold storage environments, exposure to moisture, cleaning agents, and other chemicals is inevitable. PUF sandwich panels are engineered with this in mind, featuring corrosion-resistant metal facings that protect the insulation core from degradation. This resistance to corrosion and chemical exposure significantly extends the lifespan of the panels, reducing maintenance requirements and replacement costs over time.

Structural Strength and Impact Resistance

Despite their lightweight nature, PUF sandwich panels offer impressive structural strength. The bonding between the metal facings and the polyurethane core creates a composite material that can withstand considerable loads and impacts. This structural integrity is particularly valuable in cold storage facilities, where the panels may be subjected to accidental impacts from forklifts or other equipment. The durability of PUF sandwich panels helps minimize damage and maintenance costs, contributing to the overall efficiency of the storage operation.

Cost-Effectiveness and Sustainability: The Long-Term Benefits of PUF Sandwich Panels

As businesses increasingly focus on both economic and environmental sustainability, PUF sandwich panels emerge as a solution that addresses both concerns. The long-term cost-effectiveness and eco-friendly attributes of these panels make them an attractive option for cold storage facilities looking to optimize their operations while reducing their environmental footprint.

Energy Efficiency and Operational Cost Reduction

The superior insulation properties of PUF sandwich panels translate directly into reduced energy consumption for cold storage facilities. By minimizing heat transfer and maintaining stable temperatures, these panels significantly decrease the workload on refrigeration systems. This energy efficiency not only leads to lower operational costs but also contributes to a reduced carbon footprint, aligning with sustainability goals and potentially qualifying businesses for energy-related incentives or certifications.

Rapid Installation and Minimal Maintenance

Rapid Installation and Minimal Maintenance

PUF sandwich panels are designed for quick and easy installation, reducing construction time and labor costs compared to traditional insulation methods. The modular nature of these panels allows for efficient assembly, minimizing disruptions to business operations during installation or renovations. Additionally, the low maintenance requirements of PUF sandwich panels further contribute to their cost-effectiveness, as they resist degradation and retain their insulation properties over extended periods without the need for frequent repairs or replacements.

Recyclability and Environmental Considerations

As sustainability becomes an increasingly important factor in construction and facility management, the recyclability of building materials gains prominence. PUF sandwich panels, when properly managed at the end of their lifecycle, can be recycled or repurposed, reducing waste and environmental impact. Some PUF sandwich panel manufacturers are also exploring the use of bio-based polyurethane foams, further enhancing the eco-friendly profile of these products and appealing to environmentally conscious businesses.

Conclusion

PUF sandwich panels have undeniably revolutionized cold storage solutions, offering a powerful combination of superior insulation, durability, and cost-effectiveness. Their ability to maintain precise temperature control while reducing energy consumption addresses the critical needs of modern cold storage facilities. As businesses continue to seek innovative ways to optimize their operations and reduce their environmental impact, PUF sandwich panels stand out as a versatile and reliable solution. The long-term benefits of these panels, from energy savings to reduced maintenance costs, make them an intelligent investment for any cold storage project.

Are you looking to enhance your cold storage facility with cutting-edge PUF sandwich panels? Look no further than Weifang Sandong Building Materials Co., Ltd. As a leading PUF sandwich panel manufacturer, we offer customizable, high-quality panels designed to meet your specific cold storage needs. Our panels combine exceptional insulation with durability and aesthetic appeal, ensuring optimal performance and longevity for your facility. Contact us today at info@sdqsc.com to discover how our PUF sandwich panels can revolutionize your cold storage solutions and drive your business forward.

FAQ

What makes PUF sandwich panels ideal for cold storage applications?

PUF sandwich panels offer superior insulation, moisture resistance, and durability, making them perfect for maintaining stable temperatures in cold storage facilities while reducing energy costs.

How do PUF sandwich panels contribute to energy efficiency?

The high R-value of PUF sandwich panels minimizes heat transfer, reducing the workload on refrigeration systems and leading to significant energy savings.

Are PUF sandwich panels environmentally friendly?

Yes, PUF sandwich panels can be recycled at the end of their lifecycle, and some manufacturers are developing bio-based foam options for increased sustainability.

References

1. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2017). ASHRAE Handbook: Fundamentals. ASHRAE.

2. Polyurethane Foam Association. (2021). Technical Bulletin: Thermal Performance of Polyurethane Foam. PFA.

3. International Association of Cold Storage Contractors. (2020). Best Practices for Energy Efficiency in Cold Storage Facilities. IACSC.

4. Journal of Building Engineering. (2019). "Comparative Study on Thermal Performance of Different Insulation Materials for Cold Storage Applications." Vol. 24, pp. 100-115.

5. U.S. Department of Energy. (2022). Energy Efficiency in Cold Storage Facilities. Office of Energy Efficiency & Renewable Energy.

.webp)

.webp)

Conclusion

Conclusion