The Science Behind Effective Thermal Insulation Panels

Understanding Thermal Conductivity and Resistance

At the heart of thermal insulation panel efficiency lies the science of thermal conductivity and resistance. Thermal conductivity, measured in W/m.k, indicates how easily heat flows through a material. The lower this value, the better the insulation properties. Our advanced thermal insulation panels boast an impressive thermal conductivity of 0.018W/m.k, significantly outperforming traditional insulation materials.

Complementing this is the thermal resistance, or R-value, which measures the panel's ability to resist heat flow. With a thermal resistance of 2.09m2k/w, these panels create a formidable barrier against temperature fluctuations. This translates to consistent indoor temperatures, reduced reliance on heating and cooling systems, and substantial energy savings for building occupants.

Composition and Structure: The Key to Performance

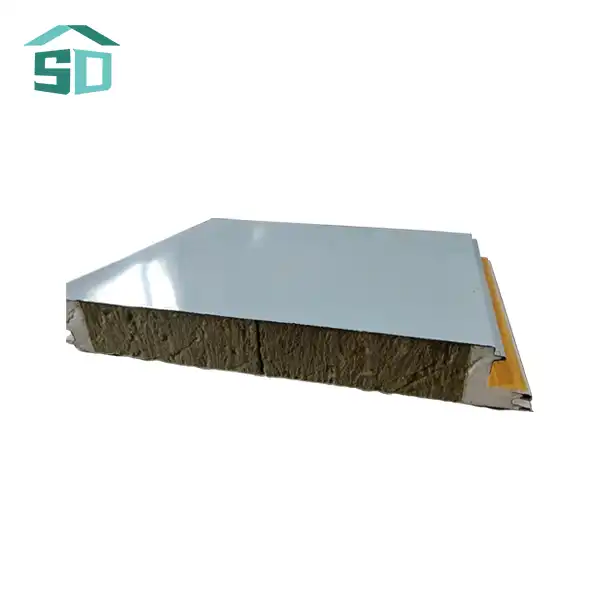

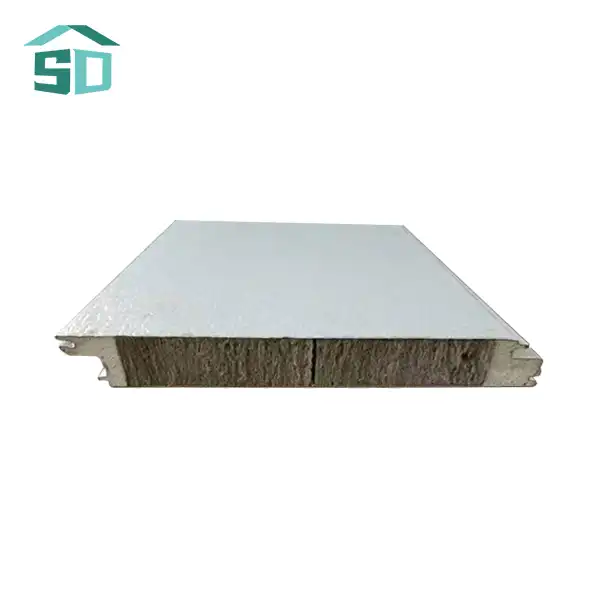

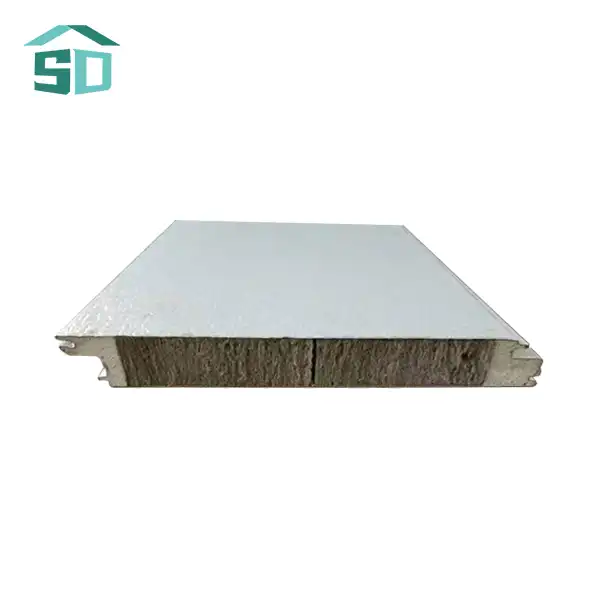

The exceptional performance of these eco-friendly thermal insulation panels stems from their innovative composition and structure. Utilizing high-quality metal materials, the panels are designed with a multi-layered approach. The core consists of advanced insulating materials, while the outer layers provide durability and weather resistance.

The thickness of these panels plays a crucial role in their insulation capabilities. For interior applications, a thickness of 10mm is typically sufficient, while exterior panels come in 16mm or 20mm options to withstand outdoor elements. The surface materials, extending from 0.23mm to 0.27mm in thickness, offer extra assurance and contribute to the panel's by and large solidness.

Environmental Benefits and Sustainability Features

Reducing Carbon Footprint Through Energy Efficiency

One of the essential natural benefits of high-performance warm cover boards is their commitment to vitality productivity. By essentially decreasing warm exchange, these boards minimize the vitality required for warming and cooling. This diminishment in vitality utilization straightforwardly interprets to lower nursery gas outflows, making a difference buildings diminish their carbon impression.

The energy savings are not just theoretical. Building owners and occupants often report substantial reductions in their energy bills after installing these thermal insulation panels. Over time, this not only offsets the initial investment but also contributes to long-term environmental sustainability.

Eco-Friendly Materials and Manufacturing Processes

The commitment to sustainability extends beyond the panels' performance to their very composition. Manufacturers like Weifang Sandong Building Materials Co., Ltd. prioritize the use of recyclable and environmentally friendly materials in their production process. This approach ensures that the panels have a minimal environmental impact throughout their lifecycle.

Moreover, the manufacturing process itself is optimized for efficiency and reduced waste. Advanced production lines and stringent quality control systems ensure that resources are used judiciously, minimizing the environmental footprint of each panel produced.

Longevity and Reduced Replacement Needs

Another often overlooked aspect of environmental sustainability is the longevity of building materials. Thermal insulation panels are designed for durability, with features like corrosion resistance, UV protection, and weather resistance. This longevity means fewer replacements over time, reducing the demand for new materials and the associated environmental costs of production and disposal.

The panels' resistance to harsh weather conditions, evidenced by their impressive wind resistance of 8.0 Kpa, ensures they maintain their performance over extended periods. This durability not only provides long-term value for building owners but also contributes to overall resource conservation.

Versatility and Practical Applications

Adaptability to Various Building Types

The versatility of thermal insulation panels makes them suitable for a wide range of building types and architectural styles. From residential complexes and offices to villas and historic building renovations, these panels can be seamlessly integrated into diverse structures. Their adaptability is particularly valuable in projects where both insulation performance and aesthetic appeal are crucial.

For instance, in municipal buildings or security kiosks, the panels' combination of insulation properties and customizable finishes allows architects to meet both functional and design requirements. The panels' ability to be used in both interior and exterior applications further enhances their versatility, providing consistent insulation throughout a structure.

Customization Options for Aesthetic Integration

One of the standout features of modern thermal insulation panels is their customizability. Architects and designers have the flexibility to choose from a variety of colors, patterns, and surface treatments. This level of customization ensures that the panels can be tailored to match or complement any architectural vision.

The panels are available in different widths - 383mm for exterior applications and 450mm for interior use - allowing for seamless integration with various wall designs. This flexibility in sizing, combined with customizable aesthetics, makes these panels a favorite among architects looking to balance form and function in their projects.

Performance in Challenging Environments

Thermal insulation panels excel not just in standard conditions but also in challenging environments. Their waterproof rate of 0.0008 makes them highly effective in areas prone to moisture, preventing water ingress and maintaining insulation efficiency. This feature is particularly valuable in coastal regions or areas with high humidity.

Additionally, the panels' fire-protection rating of B1/B2 ensures they meet strict safety standards, making them suitable for use in environments where fire safety is a critical concern. This combination of moisture resistance and fire safety expands the potential applications of these panels, making them a versatile solution for diverse building needs.

Ease of Installation and Maintenance

The practical benefits of thermal insulation panels extend to their installation and maintenance. Their lightweight design facilitates easier handling and quicker installation, reducing labor costs and project timelines. This efficiency is particularly beneficial in large-scale projects or renovations where time is of the essence.

Once installed, these panels require minimal maintenance, further enhancing their long-term value. Their resistance to corrosion, UV rays, and general wear and tear means they maintain their appearance and performance with little intervention, making them a cost-effective solution over the life of a building.

Conclusion

Eco-friendly thermal insulation panels represent a significant advancement in building technology, offering a perfect blend of performance, sustainability, and versatility. Their superior insulation properties, coupled with environmental benefits and aesthetic flexibility, make them an invaluable asset in modern construction and renovation projects. As the building industry continues to prioritize energy efficiency and sustainability, these panels stand out as a solution that truly delivers on its promises.

For those looking to explore the benefits of thermal insulation panels for their projects, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products. To learn more about our range of exterior cladding and facade solutions, including thermal insulation panels, please contact us at info@sdqsc.com. Our team is ready to help you find the perfect insulation solution for your specific needs, ensuring your project benefits from the latest in eco-friendly building technology.