Exceptional Performance Characteristics of Polyurethane Sandwich PUF Panels

Unparalleled Thermal Insulation Properties

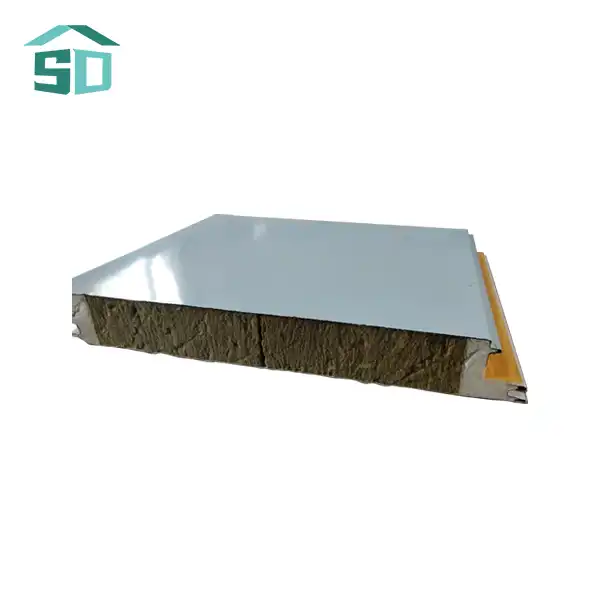

One of the most remarkable features of polyurethane sandwich PUF panels is their superior thermal insulation capabilities. With a thermal conductivity of 0.018W/m.k, these panels excel at maintaining ideal temperatures year-round, significantly reducing heating and cooling costs for buildings. This low thermal conductivity is achieved through the unique structure of the polyurethane foam core, which contains millions of tiny air pockets that effectively trap heat and prevent its transfer.

The thermal resistance of 2.09m2k/w further enhances the panels' insulation performance, ensuring that indoor spaces remain comfortable regardless of external temperature fluctuations. This exceptional insulation not only contributes to energy efficiency but also helps in creating a more sustainable built environment by reducing overall energy consumption.

Robust Fire and Moisture Resistance

Safety is paramount in construction, and polyurethane sandwich PUF panels address this concern with their impressive fire-resistant properties. Achieving a B1/B2 fire-protection rating, these panels offer enhanced fire resistance, providing occupants with valuable time for evacuation in case of emergencies. This rating indicates that the panels have undergone rigorous testing and meet stringent fire safety standards, making them suitable for use in various building types.

In addition to fire resistance, these panels boast an exceptional waterproof rate of 0.0008. This near-impermeable barrier against moisture intrusion protects the building's interior from water damage, mold growth, and other moisture-related issues. The combination of fire and moisture resistance contributes to the longevity of the structure and reduces maintenance costs over time.

Wind Resistance and Structural Integrity

Polyurethane sandwich PUF boards are designed to withstand extraordinary climate conditions, counting tall winds. With a wind resistance of 8.0 Kpa, these boards can keep up their basic astuteness indeed in ranges inclined to solid blasts or storms. This vigorous wind resistance is significant for guaranteeing the security and steadiness of buildings, especially in coastal locales or high-altitude areas where wind loads can be critical.

The panels' compressive strength of 52.7kpa further underscores their durability and load-bearing capacity. This strength allows them to withstand various external pressures without deforming or compromising their insulative properties, making them ideal for both wall and roof applications in diverse architectural designs.

Versatility and Customization Options for Polyurethane Sandwich PUF Panels

Tailored Dimensions for Project-Specific Requirements

One of the key focal points of polyurethane sandwich PUF boards is their flexibility to different venture needs. Producers offer these boards in customizable lengths, permitting planners and builders to indicate correct measurements that adjust with their plan necessities. This adaptability minimizes squander and streamlines the establishment prepare, coming about in more productive development timelines.

The panels come in different thicknesses to suit both interior and exterior applications. Interior panels typically measure 10mm in thickness, providing adequate insulation without compromising valuable floor space. Exterior panels, available in 16mm or 20mm thicknesses, offer enhanced insulation and weather resistance for optimal building envelope performance.

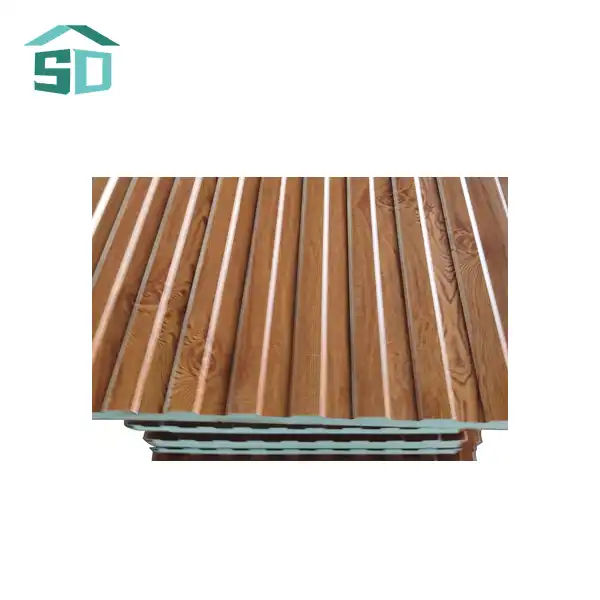

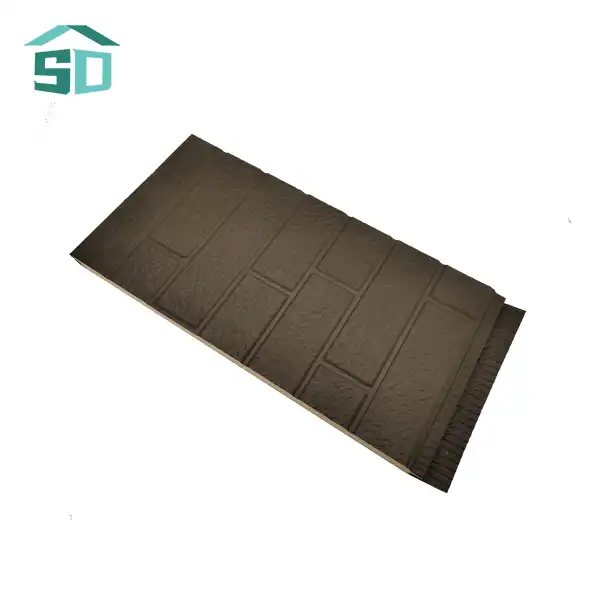

Surface Material Options and Aesthetic Versatility

Polyurethane sandwich PUF panels offer a range of surface material thicknesses, including 0.23mm, 0.25mm, and 0.27mm. These variations allow for different levels of durability and finish quality, catering to diverse project requirements and aesthetic preferences. The metal facings can be customized with various colors, patterns, and textures, enabling architects to achieve their desired visual impact while maintaining the panels' functional benefits.

This design flexibility makes polyurethane sandwich PUF panels suitable for a wide array of applications, from sleek, modern commercial facades to traditional residential exteriors. The ability to match any architectural style while providing superior insulation and durability positions these panels as a versatile solution for contemporary construction challenges.

Lightweight Construction and Installation Efficiency

Despite their robust performance characteristics, polyurethane sandwich PUF panels are remarkably lightweight. This quality significantly eases handling, transportation, and installation processes, leading to reduced labor costs and faster project completion times. The panels' lightweight nature also contributes to the overall structural efficiency of buildings, potentially allowing for more economical foundation designs and supporting structures.

The ease of installation is further enhanced by the panels' interlocking design, which facilitates rapid assembly and ensures a tight, weatherproof seal between adjacent panels. This feature not only speeds up construction but also minimizes the risk of installation errors, contributing to the long-term performance and durability of the building envelope.

Environmental and Economic Benefits of Polyurethane Sandwich PUF Panels

Sustainable Construction Practices

In an era of increasing environmental awareness, polyurethane sandwich PUF panels offer several eco-friendly advantages. The exceptional insulation properties of these panels contribute significantly to reducing a building's carbon footprint by minimizing energy consumption for heating and cooling. This energy efficiency translates to lower greenhouse gas emissions over the lifecycle of the building.

Moreover, the durability and longevity of polyurethane sandwich PUF panels mean less frequent replacements and repairs, reducing waste and resource consumption in the long term. Many manufacturers are also incorporating recycled materials into the production process and developing end-of-life recycling programs for these panels, further enhancing their sustainability credentials.

Cost-Effectiveness and Long-Term Value

Whereas the starting fetched of polyurethane sandwich PUF boards may be higher than a few conventional building materials, their long-term financial benefits are considerable. The predominant cover properties lead to critical vitality reserve funds over time, lessening operational costs for building proprietors and tenants. The panels' strength and resistance to climate, fire, and dampness too minimize upkeep and substitution costs, contributing to a lower add up to taken a toll of possession.

The rapid installation process associated with these panels can lead to reduced labor costs and earlier project completion, potentially resulting in faster return on investment for developers. Additionally, the versatility of polyurethane sandwich PUF panels allows for their use in various applications, from new construction to retrofits, making them a cost-effective solution for diverse project types.

Enhanced Building Performance and Occupant Comfort

Past their financial and natural benefits, polyurethane sandwich PUF boards essentially contribute to moved forward building execution and inhabitant consolation. The panels' fabulous warm separator properties offer assistance keep up steady indoor temperatures, lessening temperature changes and drafts. This warm soundness makes a more comfortable living and working environment, possibly expanding efficiency and well-being for building inhabitants.

The moisture resistance of these panels also contributes to better indoor air quality by preventing mold growth and reducing the risk of allergens. Combined with their fire-resistant properties, polyurethane sandwich PUF panels create safer, healthier spaces that can enhance the overall value and desirability of a property.

Conclusion

Polyurethane sandwich PUF panels represent a significant advancement in building technology, offering a unique combination of thermal efficiency, durability, and design flexibility. Their comprehensive specifications, including customizable dimensions, impressive fire and moisture resistance, and superior insulation properties, make them an ideal choice for a wide range of construction projects. As the construction industry continues to evolve towards more sustainable and efficient practices, these panels are poised to play a crucial role in shaping the future of building envelopes.

For more information on how polyurethane sandwich PUF panels can enhance your next construction project, or to explore our full range of exterior cladding and facade solutions, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs, ensuring that your building not only meets but exceeds performance expectations.