Understanding Aluminum Foam Sandwich Panels

Composition and Structure of Aluminum Foam Sandwich Panels

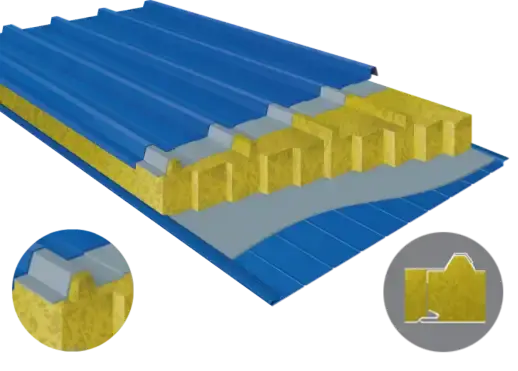

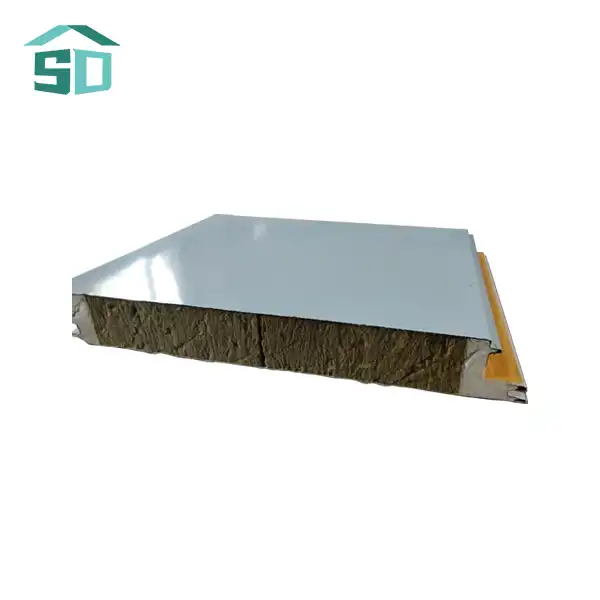

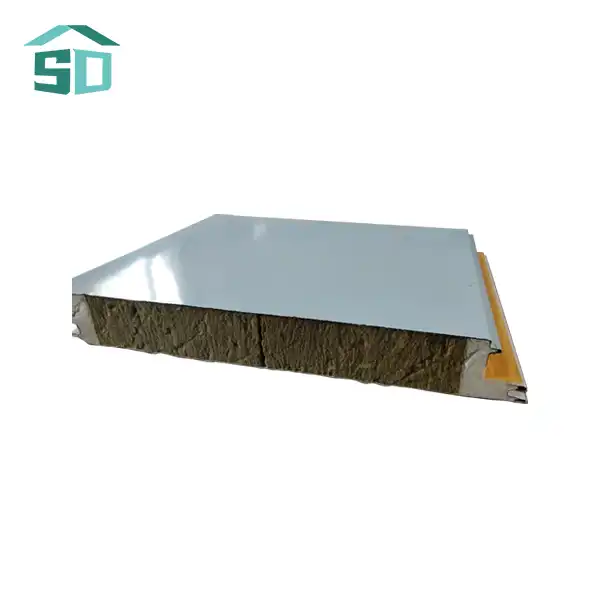

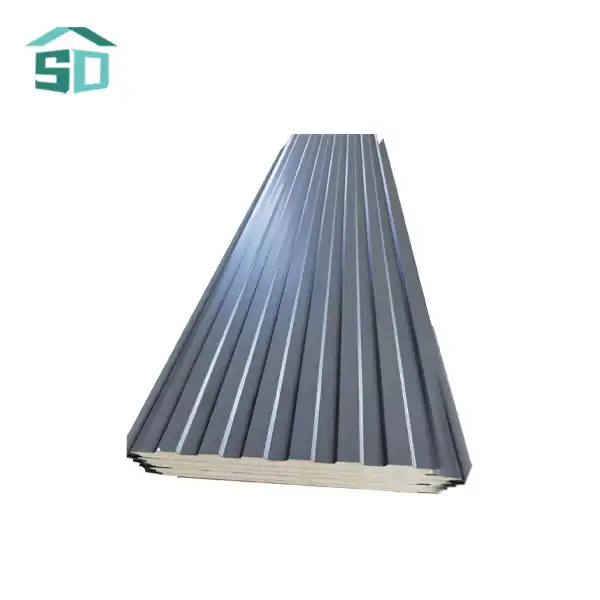

Aluminum foam sandwich panels are innovative building materials that combine lightweight properties with exceptional strength. These panels consist of two thin aluminum face sheets bonded to a core of aluminum foam. The foam core is created through a specialized process that introduces gas bubbles into molten aluminum, resulting in a cellular structure. This unique composition gives aluminum foam sandwich panels their remarkable characteristics, including high strength-to-weight ratio, excellent thermal insulation, and superior sound dampening properties.

Applications of Aluminum Foam Sandwich Panels in Construction

The versatility of aluminum foam sandwich panels makes them suitable for a wide range of construction applications. These panels are extensively used in exterior cladding, providing both aesthetic appeal and functional benefits to buildings. They are particularly popular in modern architectural designs, where their sleek appearance and customizable finishes can create striking facades.

Beyond exterior applications, aluminum foam sandwich panels are also utilized in interior partitions, ceiling systems, and even in specialized structures like clean rooms or aircraft interiors. Their lightweight nature makes them ideal for projects where weight reduction is crucial, such as in renovations of older buildings or in portable structures.

Benefits of Using Aluminum Foam Sandwich Panels

The advantages of incorporating aluminum foam sandwich panels in construction projects are numerous. Their exceptional strength-to-weight ratio allows for robust structures without the need for heavy support systems, potentially reducing overall construction costs. The thermal insulation properties of these panels contribute to energy efficiency in buildings, helping to maintain comfortable interior temperatures while reducing heating and cooling expenses.

Additionally, the sound-dampening characteristics of aluminum foam sandwich panels make them valuable in creating quieter environments, whether in office spaces, residential buildings, or industrial settings. The durability and corrosion resistance of aluminum ensure that these panels maintain their appearance and performance over time, even in challenging environmental conditions.

Preparing to Cut Aluminum Foam Sandwich Panels

Essential Tools and Equipment for Cutting Aluminum Foam Sandwich Panels

To effectively cut aluminum foam sandwich panels, it's crucial to have the right tools at your disposal. A circular saw equipped with a carbide-tipped blade designed for cutting non-ferrous metals is often the preferred choice for making straight cuts. For more intricate cuts or curves, a jigsaw with a metal-cutting blade can be utilized.

Other essential tools include a straight edge or guide rail to ensure precise cuts, clamps to secure the panel during cutting, and measuring tools such as a tape measure and marking pencil. Safety equipment is equally important; always use protective eyewear, hearing protection, and a dust mask when cutting aluminum foam sandwich panels.

Safety Precautions When Working with Aluminum Foam Sandwich Panels

Safety should be the top priority when working with aluminum foam sandwich panels. The cutting process can generate fine metal particles and dust, so proper ventilation in the work area is essential. Wearing appropriate personal protective equipment (PPE) is non-negotiable; this includes safety glasses, a respirator or dust mask, and cut-resistant gloves.

Ensure that all cutting tools are in good condition and properly maintained to prevent accidents. When handling large panels, it's advisable to work with a partner to avoid strain or injury. Always follow the manufacturer's guidelines for handling and cutting aluminum foam sandwich panels, as they may have specific recommendations based on the panel's composition.

Measuring and Marking Techniques for Precise Cuts

Accurate measurement and marking are crucial for achieving precise cuts in aluminum foam sandwich panels. Begin by carefully measuring the area where the panel will be installed, taking into account any openings or fixtures that need to be accommodated. When transferring measurements to the panel, use a straightedge and a fine-point marker or pencil to ensure clear, visible lines.

For complex shapes or curves, consider creating a template from cardboard or thin plywood first. This allows you to test the fit before making cuts on the actual panel. When marking cut lines, always double-check measurements and add a small allowance for trimming if necessary. Remember that precision at this stage will save time and material during the installation process.

Cutting and Fitting Techniques for Aluminum Foam Sandwich Panels

Step-by-Step Guide to Cutting Aluminum Foam Sandwich Panels

Cutting aluminum foam sandwich panels requires a methodical approach to ensure clean, accurate results. Begin by securing the panel firmly to a stable work surface, ensuring that the cut line is fully supported to prevent vibration during cutting. If using a circular saw, attach a guide rail or straight edge parallel to the cut line to ensure a straight cut. Set the saw blade depth to slightly exceed the thickness of the panel.

When ready to cut, start the saw before making contact with the panel and maintain a steady, consistent speed throughout the cut. For curved cuts using a jigsaw, use a slower speed and follow the marked line carefully. After cutting, inspect the edges for any burrs or roughness and smooth them with a fine-grit sandpaper if necessary.

Techniques for Fitting Aluminum Foam Sandwich Panels

Fitting aluminum foam sandwich panels requires attention to detail and proper technique to ensure a seamless installation. Begin by dry-fitting the cut panels in their intended location to check for proper alignment and make any necessary adjustments. When installing panels as exterior cladding, ensure that the substrate is clean, dry, and properly prepared according to manufacturer specifications. Use appropriate fasteners or adhesives as recommended for the specific type of aluminum foam sandwich panels you're working with.

For panels that need to be joined, consider using specialized connectors or profiles designed for aluminum foam sandwich panels to create clean, weather-tight seams. Pay special attention to corners and edges, using corner pieces or custom-fabricated bends to achieve a polished look.

Troubleshooting Common Issues When Working with Aluminum Foam Sandwich Panels

While aluminum foam sandwich panels are generally easy to work with, certain challenges may arise during the cutting and fitting process. One common issue is the occurrence of rough or uneven edges after cutting. This can be addressed by using a finer-toothed blade or by sanding the edges carefully after cutting. If panels become slightly warped during storage or transport, they can often be gently flattened by applying even pressure or using temporary bracing during installation.

When fitting panels around complex shapes or protrusions, it may be necessary to make multiple small cuts rather than attempting a single complex cut. If adhesive bonding is used, ensure proper curing time and conditions are observed to prevent premature failure. For any persistent issues or specialized applications, consult with the manufacturer or a professional experienced in working with aluminum foam sandwich panels.

Conclusion

Mastering the art of cutting and fitting aluminum foam sandwich panels is essential for achieving high-quality results in construction projects. By understanding the unique properties of these panels, employing the right tools and techniques, and following safety guidelines, professionals can efficiently incorporate these versatile materials into various architectural designs. The lightweight yet durable nature of aluminum foam sandwich panels, combined with their excellent thermal and acoustic properties, makes them an invaluable asset in modern construction. As the industry continues to evolve, the demand for skilled professionals who can expertly work with these innovative materials is likely to grow.

Are you looking to elevate your next construction project with cutting-edge materials? Explore the possibilities of aluminum foam sandwich panels with Weifang Sandong Building Materials Co., Ltd. Our expertise in exterior cladding and facade solutions can help bring your architectural vision to life. For more information on our products and services, including aluminum foam sandwich panels OEM options, don't hesitate to reach out to us at info@sdqsc.com.

FAQ

Can aluminum foam sandwich panels be recycled?

Yes, aluminum foam sandwich panels are recyclable. The aluminum components can be separated and recycled through standard aluminum recycling processes.

Are special tools required for cutting aluminum foam sandwich panels?

While specialized tools are not always necessary, using a circular saw with a carbide-tipped blade designed for non-ferrous metals typically yields the best results.

How do aluminum foam sandwich panels compare to traditional building materials in terms of insulation?

Aluminum foam sandwich panels often provide superior insulation compared to many traditional materials due to their foam core structure, which traps air and reduces heat transfer.

References

1. Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science, 46(6), 559-632.

2. Ashby, M. F., Evans, A., Fleck, N. A., Gibson, L. J., Hutchinson, J. W., & Wadley, H. N. G. (2000). Metal Foams: A Design Guide. Butterworth-Heinemann.

3. Baumeister, J., Banhart, J., & Weber, M. (1997). Aluminium foams for transport industry. Materials & Design, 18(4-6), 217-220.

4. Degischer, H. P., & Kriszt, B. (Eds.). (2002). Handbook of cellular metals: production, processing, applications. Wiley-VCH.

5. Gibson, L. J., & Ashby, M. F. (1997). Cellular solids: structure and properties. Cambridge University Press.