- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Durable Are Insulated Metal Sandwich Panels in Construction?

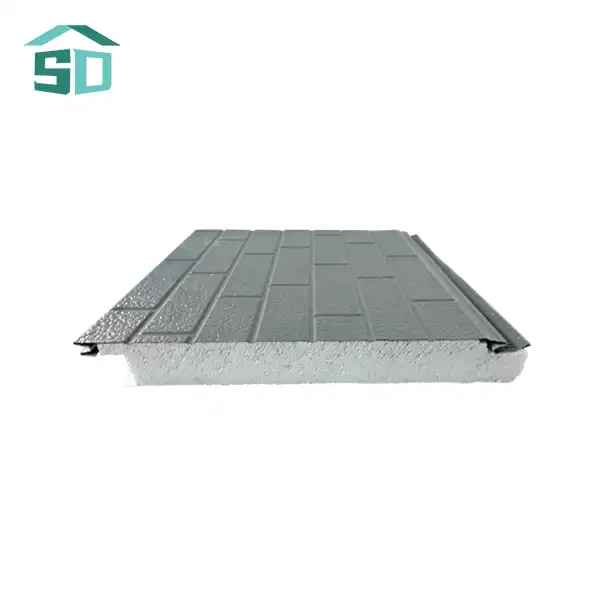

Insulated Metal Sandwich Panels are exceptionally durable in construction, offering a robust and long-lasting solution for modern buildings. These panels typically boast a lifespan of 40-50 years, with some high-quality variants lasting even longer under proper maintenance. Their durability stems from a combination of factors: the sturdy metal outer layers, the resilient insulation core, and advanced manufacturing techniques. Resistant to environmental stressors, fire, and corrosion, these panels maintain their structural integrity and insulation properties over time.

The Anatomy of Durability: Understanding Insulated Metal Sandwich Panel Construction

To truly appreciate the durability of Insulated Metal Sandwich Panels, it's crucial to delve into their construction. These panels are a marvel of modern engineering, combining multiple layers to create a synergistic structure that's greater than the sum of its parts.

Metal Exterior: The First Line of Defense

The outer layers of Insulated Metal Sandwich Panels are typically made from high-grade steel or aluminum. These metals are chosen for their strength, resilience, and ability to withstand various environmental factors. The metal exterior acts as a protective shield, safeguarding the interior components from physical damage, UV radiation, and moisture infiltration.

Weifang Sandong Building Materials Co., Ltd. utilizes advanced production lines and rigorous quality control systems to ensure the metal used in their panels meets the highest standards. Each steel coil undergoes comprehensive inspections for thickness, paint film durability, and mechanical strength, guaranteeing a robust exterior that stands the test of time.

Insulation Core: The Heart of Performance

Sandwiched between the metal layers is the insulation core, often composed of materials like polyurethane, polyisocyanurate, or mineral wool. This core is not just about thermal efficiency; it also contributes significantly to the panel's overall structural integrity and longevity.

The insulation core is meticulously tested for flame retardancy and density, ensuring it meets stringent safety standards while providing optimal insulation properties. This careful selection and testing of materials result in a core that maintains its performance characteristics over decades, resisting compression and degradation.

Bonding Technology: Unifying Strength

The durability of Insulated Metal Sandwich Panels is further enhanced by the advanced bonding technology used to unite the metal skins with the insulation core. This process creates a monolithic panel that distributes loads evenly and resists delamination, even under extreme conditions.

The bonding process employed by industry leaders like Weifang Sandong Building Materials Co., Ltd. ensures a seamless integration of components. This results in panels that are not only durable but also maintain their structural integrity and insulation properties throughout their lifespan, contributing to the overall longevity of the building envelope.

Resilience in Action: How Insulated Metal Sandwich Panels Withstand Environmental Challenges?

The true test of durability comes when materials face real-world conditions. Insulated Metal Sandwich Panels excel in this regard, demonstrating remarkable resilience against a variety of environmental challenges that would deteriorate lesser materials.

Weather Resistance: Standing Strong Against the Elements

One of the primary factors contributing to the longevity of Insulated Metal Sandwich Panels is their exceptional weather resistance. These panels are engineered to withstand extreme temperature fluctuations, heavy rainfall, snow loads, and intense UV radiation without compromising their structural integrity or insulation properties.

The metal exterior is often treated with specialized coatings that enhance its resistance to corrosion and fading. This means that even after years of exposure to harsh sunlight or coastal salt spray, the panels maintain their appearance and protective qualities. The tight seals between panels also prevent water infiltration, a common cause of structural damage in buildings.

Fire Resistance: A Critical Safety Feature

Fire safety is a paramount concern in construction, and Insulated Metal Sandwich Panels address this with their inherent fire-resistant properties. The non-combustible metal facings and fire-retardant insulation core work in tandem to slow the spread of flames and maintain structural integrity during a fire event.

Many Insulated Metal Sandwich Panels are rated for up to 3 hours of fire resistance, providing crucial time for evacuation and firefighting efforts. This fire-resistant quality not only enhances the safety of the building's occupants but also contributes to the overall durability of the structure by protecting it from fire-related damage.

Chemical and Biological Resistance: Combating Unseen Threats

In addition to visible environmental factors, Insulated Metal Sandwich Panels also demonstrate impressive resistance to chemical and biological threats. The inert nature of the metal exterior makes it impervious to many chemicals that could degrade other building materials.

Long-Term Performance: The Economic and Sustainable Advantages of Durable Insulated Metal Sandwich Panels

The durability of Insulated Metal Sandwich Panels translates into significant economic and environmental benefits over the lifetime of a building. These advantages make them an increasingly popular choice for architects, builders, and property owners who prioritize long-term performance and sustainability.

Reduced Maintenance and Replacement Costs

One of the most tangible benefits of using durable Insulated Metal Sandwich Panels is the reduction in maintenance and replacement costs over time. Unlike traditional building materials that may require frequent painting, sealing, or replacement, these panels maintain their performance and appearance with minimal upkeep.

The corrosion-resistant properties of the metal exterior mean that even in harsh environments, the panels resist rust and degradation. This longevity translates to fewer repair and replacement cycles, significantly reducing the lifecycle costs of the building. For property owners and facility managers, this means more predictable budgeting and fewer disruptions due to maintenance activities.

Energy Efficiency and Cost Savings

The durability of Insulated Metal Sandwich Panels extends beyond their physical structure to their thermal performance. The high-quality insulation core maintains its R-value over decades, ensuring consistent energy efficiency throughout the life of the building.

This sustained thermal performance leads to substantial energy savings year after year. Buildings clad with these panels require less energy for heating and cooling, resulting in lower utility costs and reduced strain on HVAC systems. Over the lifespan of the building, these savings can amount to a significant return on investment, making Insulated Metal Sandwich Panels a cost-effective choice in the long run.

Environmental Impact and Sustainability

The durability of Insulated Metal Sandwich Panels also contributes to their environmental sustainability. By lasting longer and requiring fewer replacements, these panels reduce the demand for raw materials and the energy associated with manufacturing and transporting new building materials.

Moreover, at the end of their long service life, many components of Insulated Metal Sandwich Panels are recyclable. The metal facings can be reclaimed and repurposed, further reducing the environmental impact. This aligns with the growing emphasis on circular economy principles in the construction industry, where materials are designed for longevity and eventual recycling.

Conclusion

The durability of Insulated Metal Sandwich Panels in construction is not just impressive; it's transformative. These panels offer a rare combination of longevity, performance, and sustainability that is reshaping expectations in the building industry. From their resilient metal exteriors to their high-performance insulation cores, every aspect of their design contributes to a structure that stands strong against time and elements.

To learn more about how Insulated Metal Sandwich Panels can enhance your next construction project, or to discuss your specific needs, don't hesitate to reach out to the experts at Weifang Sandong Building Materials Co., Ltd. Contact them at info@sdqsc.com for personalized guidance and solutions that will stand the test of time.

References

1. American Iron and Steel Institute. "The Sustainability of Steel: Strength and Durability." 2021.

2. National Institute of Building Sciences. "Whole Building Design Guide: Building Envelope Design Guide." 2018.

3. U.S. Department of Energy. "Building Energy Codes Program: Insulation Requirements." 2022.

4. International Code Council. "International Building Code." 2021 Edition.

5. Weifang Sandong Building Materials Co., Ltd. Official Product Specifications and Testing Reports. 2023.