The Innovative Structure of Metal Foam Sandwich Panels

Composition and Manufacturing Process

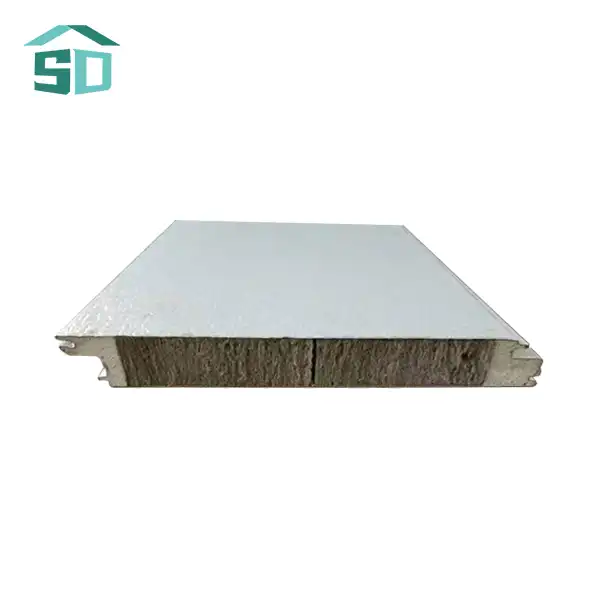

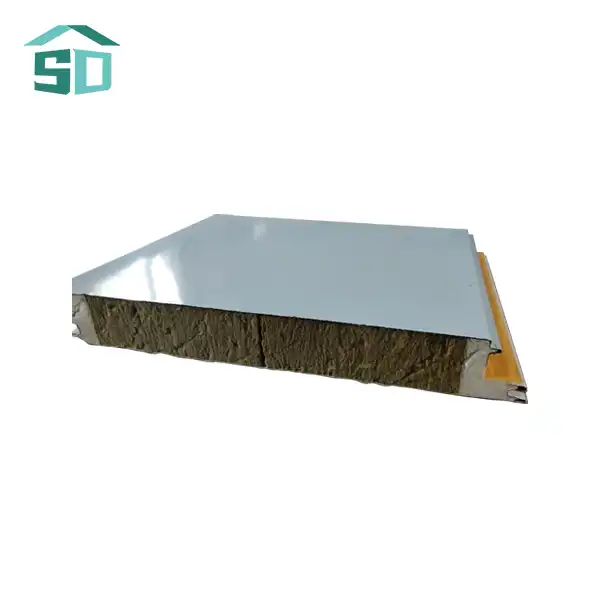

Metal foam sandwich panels are a marvel of modern engineering, combining the strength of metal with the lightweight properties of foam. The core of these panels consists of a specially engineered metal foam, typically made from aluminum or other lightweight alloys. This foam is created through a process called foaming, where gas bubbles are introduced into molten metal, resulting in a highly porous yet remarkably strong material.

The manufacturing process involves sandwiching this metal foam core between two thin sheets of solid metal, which can be aluminum, steel, or other alloys depending on the specific application requirements. These outer layers are bonded to the core using advanced adhesive technologies or mechanical fastening methods, ensuring a strong and durable composite structure.

Unique Properties and Advantages

The distinctive structure of metal foam sandwich panels confers a range of advantageous properties:

- Exceptional Strength-to-Weight Ratio: The metal foam core provides substantial structural strength while keeping the overall weight of the panel low, making it ideal for both load-bearing and non-load-bearing applications.

- Superior Thermal Insulation: The porous nature of the metal foam core creates numerous air pockets, significantly enhancing the panel's thermal insulation properties. This leads to improved energy efficiency in buildings, reducing heating and cooling costs.

- Acoustic Dampening: The unique structure of metal foam effectively absorbs sound waves, making these panels an excellent choice for noise reduction in various architectural settings.

- Fire Resistance: Many metal foam sandwich panels are designed with fire-resistant properties, enhancing the safety of structures in which they are used.

Customization Options for Unique Architectural Expressions

Surface Finishes and Textures

One of the most compelling aspects of metal foam sandwich panels is their high degree of customizability, particularly in terms of surface finishes and textures. Architects and designers have a vast array of options at their disposal to create truly unique exterior appearances:

- Metallic Finishes: Panels can be finished with various metallic coatings, including brushed aluminum, polished stainless steel, or even copper patinas, offering a range of lustrous and contemporary looks.

- Powder Coating: A wide spectrum of colors and textures can be achieved through powder coating, allowing for precise color matching to architectural schemes or brand identities.

- Embossed Patterns: The outer metal sheets can be embossed with intricate patterns or textures, adding depth and visual interest to facades.

- Perforations: Custom perforations can be added to the panels, creating unique light and shadow effects or improving ventilation in certain applications.

Panel Shapes and Sizes

Metal foam sandwich panels offer remarkable flexibility in terms of shape and size, enabling architects to push the boundaries of traditional design:

- Curved Panels: The panels can be manufactured in curved or bent shapes, allowing for the creation of fluid, organic architectural forms.

- Custom Sizes: Panels can be produced in a wide range of sizes, from small decorative elements to large-scale cladding units, accommodating various architectural needs.

- Modular Systems: Designers can create modular panel systems that interlock or combine in innovative ways, facilitating unique facade patterns and textures.

Applications and Design Possibilities

Exterior Facade Solutions

Metal foam sandwich panels excel as exterior cladding solutions, offering a perfect balance of aesthetics and functionality:

- Commercial Buildings: These panels can create striking, modern facades for office buildings, retail centers, and institutional structures, providing a sleek, contemporary look while ensuring energy efficiency.

- Residential Complexes: In multi-family housing and high-end residential projects, metal foam panels offer a luxurious appearance combined with practical benefits such as sound insulation and thermal performance.

- Industrial Facilities: The durability and customizable nature of these panels make them ideal for industrial buildings, where both aesthetics and functionality are crucial.

Interior Design Applications

Beyond exterior use, metal foam sandwich panels have found innovative applications in interior design:

- Decorative Wall Panels: Custom-designed panels can serve as stunning focal points in lobbies, reception areas, or high-end residential spaces.

- Acoustic Solutions: The sound-dampening properties of metal foam panels make them excellent choices for concert halls, recording studios, or open-plan offices where noise control is essential.

- Partition Walls: Lightweight yet sturdy, these panels can be used to create flexible, movable partition walls in dynamic office environments or exhibition spaces.

Conclusion

Customizable metal foam sandwich panels represent a revolutionary material in the world of architectural design. Their unique combination of strength, lightness, and adaptability opens up a world of creative possibilities for architects and designers. From striking exterior facades to innovative interior solutions, these panels offer the perfect blend of form and function. As the demand for sustainable, energy-efficient, and aesthetically pleasing building materials continues to grow, metal foam sandwich panels are poised to play an increasingly important role in shaping the built environment of the future.

For more information about our range of exterior cladding and facade solutions, including metal foam sandwich panels, please contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is dedicated to providing you with the highest quality products and unparalleled service to enhance your architectural projects.