Selecting the right OEM/ODM supplier for prefab house projects requires careful evaluation of technical capabilities, quality standards, and service reliability. Working with makers who know a lot about portable building solutions and can give you consistent, weatherproof structures that meet regulations is very important for the success of your modular construction project. This complete guide goes over important things you should look for in container house sellers. It will help you protect your investment and make sure the project is a success.

Understanding OEM vs ODM Manufacturing Models

Knowing the difference between OEM and ODM relationships is important for the success of projects that involve modular homes or container houses. Original Equipment Manufacturing (OEM) agreements let you use designs that have already been made while changing things like the exterior siding, the plan of the inside, or the structural requirements. This method usually has shorter lead times and lower building costs, which makes it perfect for big housing projects or emergency relief housing programs.

Original Design Manufacturing (ODM) partnerships give you more creative freedom over the specs of your movable building. ODM suppliers work closely with architectural design companies to come up with one-of-a-kind solutions that are perfect for the site, the climate, or the client's personal style. This model works especially well for business real estate projects that need unique modern architecture or specific off-grid living features.

Choosing between OEM and ODM has a big effect on how long the job takes, how much money you have, and how many customization options you have. When looking at these production models, you should think about the needs of your target market, the rules you have to follow, and your long-term business goals.

Essential Quality Standards and Certifications

Quality control is an important part of making container homes that can't be skipped. Supply companies with a good reputation keep a full set of certifications that show they follow international safety and building rules. Look for ISO 9001 quality management certifications. These show that quality control is done in a planned way throughout the whole producing process.

It is especially important to test the structural stability of lightweight structures and foldable container homes. Make sure that any possible suppliers you are considering do thorough tests of their load capacities, wind resistance, and seismic performance. These tests make sure that your small house or mobile home projects can stand up to the stresses of the environment while keeping people safe.

When looking at eco-friendly building materials for a prefab house, fire resistance scores should be given extra attention. Good suppliers keep thorough records of the results of flame retardancy tests and make sure they follow local fire safety rules. For government projects and business real estate developments that need certain safety certifications, this paperwork is very important.

Environmental certifications are becoming more and more important in the buying process for green home projects. Suppliers who commit to using eco-friendly manufacturing methods, recyclable materials, and energy-efficient design principles are in line with the current trend in the building industry to be more responsible with the environment.

Technical Capabilities and Customization Options

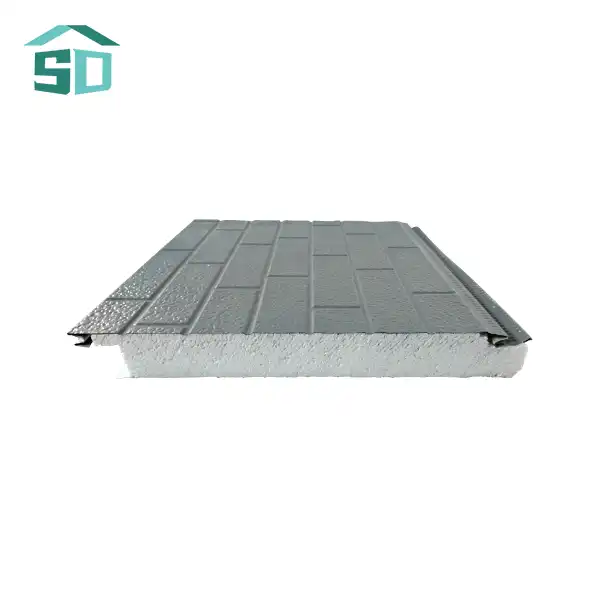

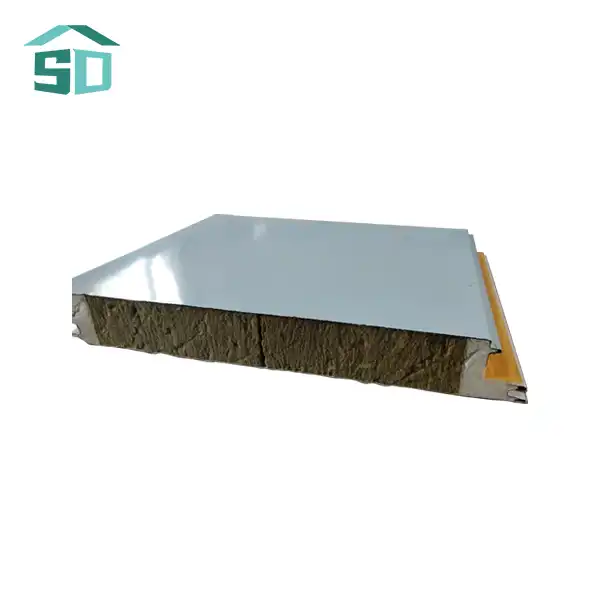

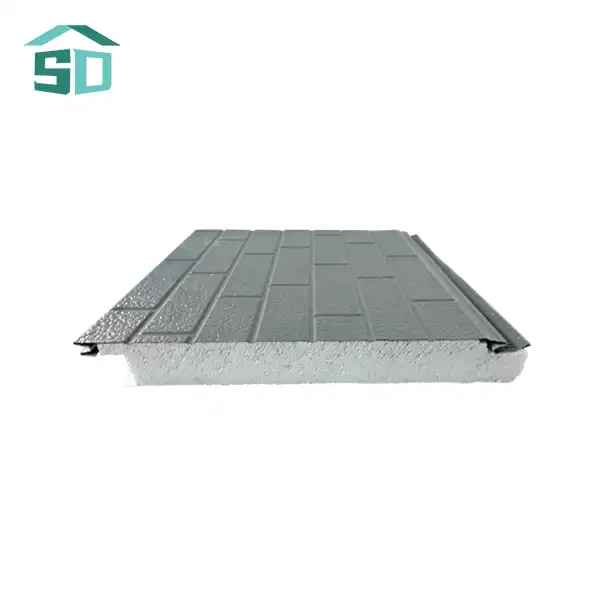

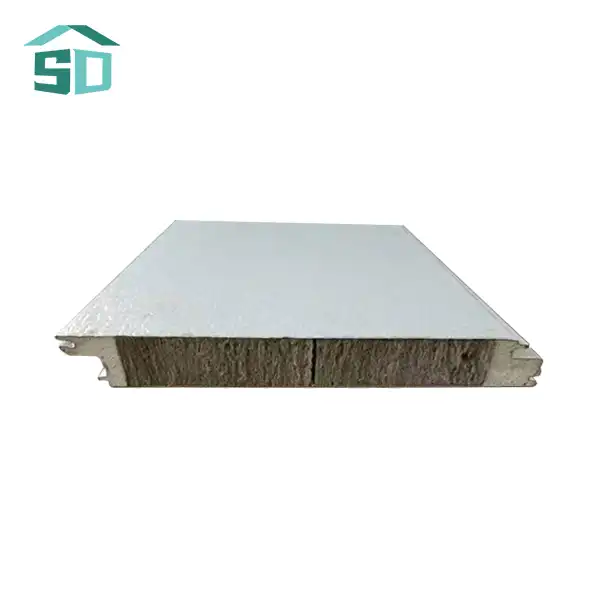

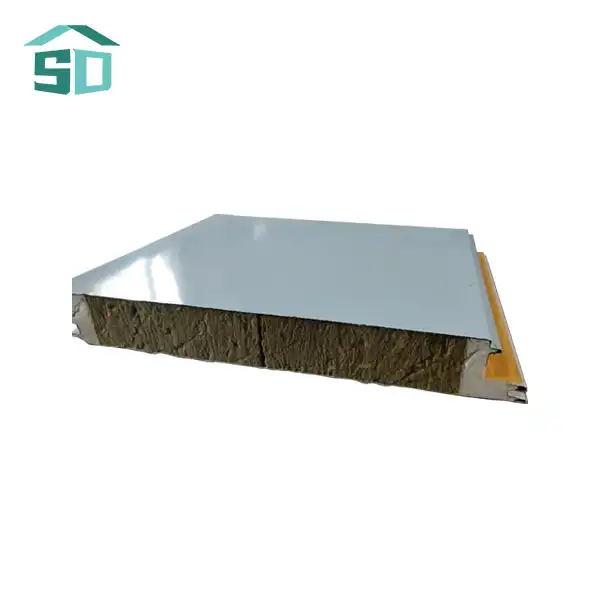

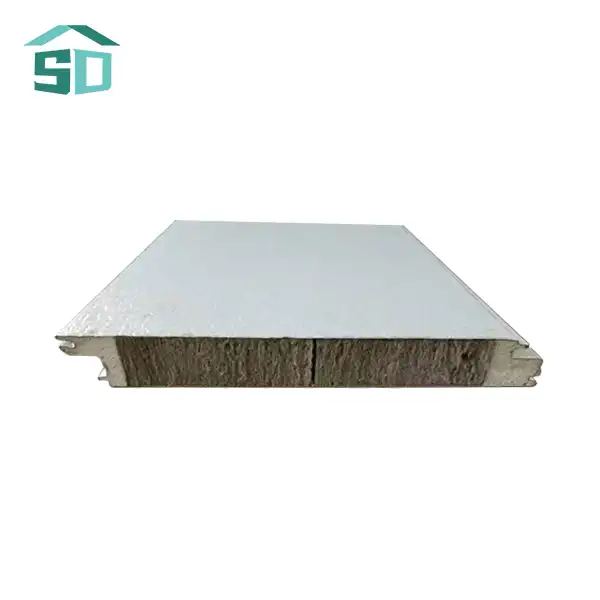

Assessing technical knowledge helps separate sellers who are capable from those who lack basic manufacturing skills. Check to see how much experience the provider has with building steel-framed homes, integrating insulated sandwich panels, and using advanced cladding systems. These technical skills have a direct effect on how long your end product lasts and how well it works.

How well suppliers can change to the needs of a specific project depends on how flexible their customization options are. Check to see how well they can change basic designs to fit different climates, architectural styles, or needs. This adaptability is especially important for pre-engineered building projects that need to meet specific needs or be used in specific ways.

Production power and scalability affect how long a project takes and how much it costs. For big orders, suppliers with new factories and automated production lines usually offer better quality control, shorter lead times, and more competitive prices. Check out their equipment, staff size, and ability to adjust production to meet the needs of the job.

Supplier relationships are much more valuable when they include technical support services throughout the lifecycle of a project. Look for makers that offer support services after the product has been delivered, help with installation, and design advice. These services are especially helpful for complicated temporary shelter setups or affordable housing projects that need ongoing technology support.

Supply Chain Reliability and Delivery Performance

Stability in the supply chain has a direct effect on the success of a project, especially for phased building projects that need exact delivery dates. Check out how producers work with people who provide raw materials, their transportation networks, and their ability to handle logistics. Reliable sellers keep extra stock on hand and offer different ways to get goods so that disruption risks are kept to a minimum.

Location affects the cost of transportation, the time it takes to send goods, and how well people can talk to each other. For international projects, suppliers near big shipping ports or transportation hubs can often save money. For domestic building projects, however, being close to your project sites may be more important than saving money on transportation.

Communication protocols and tools for tracking deliveries make sure that the whole procurement process is clear. Today's suppliers offer real-time tracking of shipments, proactive progress updates, and dedicated customer service contacts. These skills are necessary to make sure that deliveries of complicated flat-pack houses don't interfere with building schedules.

Risk management plans protect against problems with supplies that could cause a project to take longer than planned to finish. Check to see if providers have backup plans, insurance, and are financially stable. Suppliers with a variety of manufacturing sites and backup plans are better able to handle problems that come up out of the blue.

Cost Structure Analysis and Value Assessment

Cost Structure Analysis and Value Assessment

A full cost analysis looks at more than just the original purchase price. It also looks at the total costs of owning the project over its entire lifecycle. Consider transportation costs, assembly requirements, maintenance needs, and possible warranty claims when comparing supplier proposals. When you look at things as a whole, you can see what the real value is and avoid spending more than you planned.

Being clear about prices builds trust and makes it possible to make accurate budgets for a prefab house project. Suppliers you can trust give you thorough cost breakdowns that show how much the materials cost, how much it costs to make, and your profit margins. This level of openness makes talks more productive and helps find ways to cut costs without sacrificing quality.

When you place a big order, the price goes down significantly because of volume pricing. Check to see if suppliers are willing to give varying prices, discounts for large orders, or long-term partnerships. These pricing models work especially well for big real estate companies who are working on a lot of projects at once.

Different project financing models can be accommodated by payment terms and financial flexibility. Suppliers who offer flexible payment schedules, billing based on progress, or longer credit terms are helpful for complicated projects that need to be built over a long period of time or that need government support.

Reference Projects and Industry Experience

Portfolio evaluation shows you how much experience providers have with projects that are similar to yours. Ask for detailed case studies that show successful developments of shipping container homes, commercial modular construction projects, or unique uses that are important to your business. These examples show that you have real-world knowledge and can solve problems.

Testimonials and references from clients can tell you a lot about a supplier's work, service, and how well they handle relationships with customers. Talk to past customers about their experiences, any problems they had, and how satisfied they were overall. This feedback helps find possible problems and backs up what the supplier says about their skills.

Industry awards and recognition show that a provider is a leader in innovation and quality. When suppliers get awards or praise from their peers, it's usually because they have great expert skills and are dedicated to always getting better. These accomplishments give people more faith in choices about which suppliers to choose.

Project complexity and scale comparisons can help you figure out if a provider can meet your needs. Suppliers who have managed big housing developments or technically difficult projects before are likely to have the skills and resources needed for complicated projects.

Conclusion

Successful supplier selection for prefab house and container house projects requires systematic evaluation of technical capabilities, quality standards, and service reliability. The investment in thorough supplier assessment pays dividends through improved project outcomes, reduced risks, and enhanced long-term performance. By focusing on these essential criteria and partnering with experienced manufacturers like Weifang Sandong Building Materials, you can confidently move forward with projects that meet your quality expectations, budget requirements, and delivery schedules while building lasting relationships that support future growth initiatives.

Partner with Weifang Sandong Building Materials for Your Next Prefab House Project

Weifang Sandong Building Materials Co., Ltd. is a reliable company that can supply you with prefab houses. They provide full OEM/ODM services for modular building projects all over the world. Our many years of experience working with general contractors, real estate developers, and architectural design companies in more than 30 countries makes us the best people to understand your needs and give you great results.

Our state-of-the-art factories make insulated sandwich panels, high-quality exterior wall claddings, and other building supplies that are necessary for making container homes. We work together with big names in the industry, like Baosteel, Akzo Nobel, and KCC, to make sure that all of our products have the best materials and act the same way.

At our sites, we have thorough quality inspection processes that include testing steel parts, coating systems, and structural elements very carefully. As part of our dedication to technical excellence, we offer full project support, from the initial design consultation to installation help and ongoing service support.

Whether you require standard modular solutions or customized designs for unique applications, our technical team collaborates closely with your engineering and design professionals to optimize performance, aesthetics, and cost-effectiveness. Ready to explore how our expertise can benefit your next project? contact us at info@sdqsc.com to discuss your requirements and receive detailed project proposals.

References

1. Johnson, M. & Stevens, R. (2023). "Modular Construction Quality Standards: A Comprehensive Analysis of OEM/ODM Manufacturing Processes." International Journal of Prefabricated Building Technology, 45(3), 78-92.

2. Chen, L. (2022). "Supply Chain Management in Container House Manufacturing: Best Practices for Procurement Professionals." Construction Industry Review, 28(7), 156-171.

3. Anderson, K. et al. (2023). "Cost-Benefit Analysis of OEM vs ODM Partnerships in Modular Housing Development." Building Economics Quarterly, 19(2), 234-248.

4. Williams, P. & Thompson, A. (2022). "Quality Assurance Protocols for Prefabricated Building Components: Industry Standards and Certification Requirements." Structural Engineering International, 31(4), 445-459.

5. Martinez, S. (2023). "Risk Assessment in Modular Construction Supplier Selection: A Decision Framework for Project Managers." Project Management in Construction, 15(6), 89-104.

6. Liu, H. & Brown, D. (2022). "Sustainable Manufacturing Practices in the Prefabricated Housing Industry: Environmental Impact and Certification Standards." Green Building Materials Journal, 12(9), 312-327.