The Science Behind Fire-Resistant Polyurethane Foam Sandwich Panels

Chemical Composition and Fire-Retardant Properties

Polyurethane froth sandwich boards are designed with a interesting chemical composition that upgrades their fire-resistant properties. The center of these boards is made from a specialized polyurethane froth that contains fire-retardant added substances. These added substances work by making a char layer when uncovered to tall temperatures, viably abating down the spread of flares and lessening warm exchange. The chemical structure of the froth too incorporates halogenated compounds, which discharge flame-inhibiting gasses when warmed, advance stifling fire proliferation.

Thermal Insulation and Heat Control Mechanisms

One of the key focal points of polyurethane froth sandwich boards is their extraordinary warm cover capabilities. The closed-cell structure of the froth makes minor discuss pockets that essentially decrease warm exchange through conduction and convection. This warm productivity not as it were contributes to vitality investment funds but moreover plays a significant part in fire resistance. By minimizing warm exchange, these boards offer assistance keep up lower temperatures on the unexposed side amid a fire occasion, giving important time for tenants to empty and for firefighters to react.

Testing and Certification Standards

Fire-resistant polyurethane foam sandwich panels undergo rigorous testing to ensure they meet stringent safety standards. These tests typically include flame spread ratings, smoke development indices, and fire resistance ratings. The panels are subjected to controlled fire conditions to evaluate their performance in real-world scenarios. Certification bodies such as Underwriters Laboratories (UL) and Factory Mutual (FM) provide independent verification of the panels' fire-resistant properties, giving builders and architects confidence in their safety performance.

Design Versatility and Customization Options

Aesthetic Flexibility and Color Choices

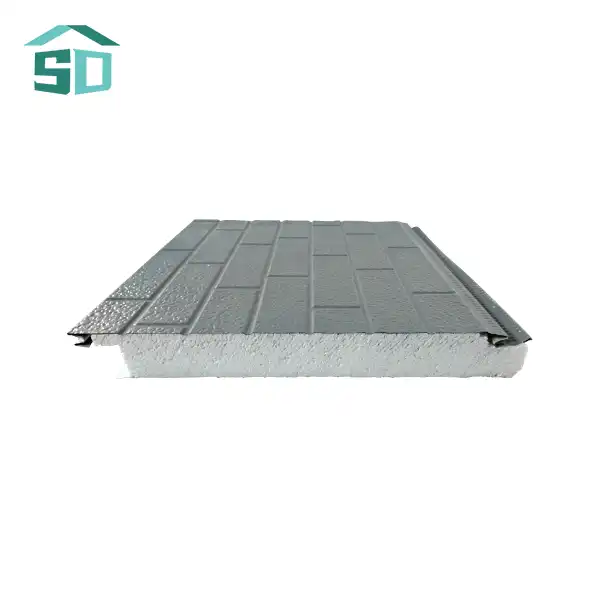

While safety is paramount, the aesthetic appeal of building materials remains a crucial consideration for architects and designers. Fire-resistant polyurethane foam sandwich panels offer a wide range of customization options to meet diverse design requirements. These panels can be manufactured in various colors, textures, and finishes, allowing for seamless integration with different architectural styles. From sleek, modern looks to traditional appearances, the versatility of these panels ensures that safety does not come at the expense of visual appeal.

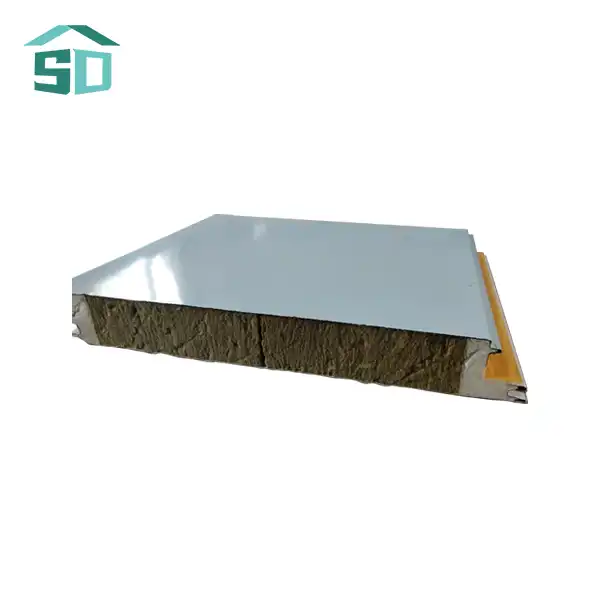

Panel Dimensions and Configurations

The flexibility in panel dimensions and configurations is another advantage of fire-resistant polyurethane foam sandwich panels. Manufacturers can produce these panels in custom sizes to fit specific project requirements, reducing on-site modifications and improving installation efficiency. Additionally, the panels can be designed with different core thicknesses to achieve desired insulation values without compromising fire resistance. This adaptability makes them suitable for a wide range of applications, from small residential projects to large-scale commercial buildings.

Integration with Other Building Systems

Fire-resistant polyurethane foam sandwich panels are designed to integrate seamlessly with other building systems and components. They can be engineered to accommodate various fastening methods, allowing for easy installation with different structural systems. The panels can also be designed with built-in channels or cavities for electrical wiring, plumbing, or HVAC systems, streamlining the construction process and reducing potential points of failure in fire safety. This integration capability ensures that the fire-resistant properties of the panels work in harmony with the overall building design and safety systems.

Long-Term Benefits and Cost Considerations

Energy Efficiency and Operational Cost Savings

The superior thermal insulation properties of fire-resistant polyurethane foam sandwich panels translate into significant energy savings over the lifecycle of a building. By reducing heat transfer and air leakage, these panels help maintain consistent indoor temperatures, reducing the load on heating and cooling systems. This energy efficiency not only lowers operational costs but also contributes to a building's overall sustainability profile. The long-term cost savings associated with reduced energy consumption can offset the initial investment in high-quality fire-resistant panels.

Durability and Maintenance Requirements

Fire-resistant polyurethane foam sandwich panels are engineered for longevity and durability. The panels are resistant to moisture, corrosion, and UV radiation, ensuring they maintain their structural integrity and fire-resistant properties over time. This durability translates to lower maintenance requirements and reduced replacement costs compared to traditional building materials. The panels' resistance to environmental factors also helps preserve their aesthetic appearance, reducing the need for frequent repainting or refinishing.

Life Cycle Cost Analysis and Return on Investment

When assessing the cost-effectiveness of fire-resistant polyurethane froth sandwich boards, it's basic to consider their life cycle costs. Whereas the beginning venture may be higher than a few conventional materials, the long-term benefits regularly result in a favorable return on speculation. Variables such as diminished vitality costs, lower protections premiums due to improved fire security, and diminished upkeep costs contribute to the in general cost-effectiveness of these boards. Furthermore, the potential to dodge disastrous misfortunes in the occasion of a fire advance underscores the esteem recommendation of contributing in high-quality fire-resistant building materials.

Conclusion

Fire-resistant polyurethane foam sandwich panels represent a significant advancement in building safety and energy efficiency. By combining robust fire protection with exceptional insulation properties, these panels offer a comprehensive solution for modern construction needs. Their versatility in design, coupled with long-term cost benefits, makes them an attractive choice for architects, builders, and property owners alike.

As the construction industry continues to prioritize safety and sustainability, fire-resistant polyurethane foam panels are poised to play an increasingly important role in shaping the built environment of the future. For more information about our fire-resistant polyurethane foam sandwich panels and other exterior cladding and facade solutions, please contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is ready to assist you in finding the perfect solution for your construction needs.