The Science Behind Fire-Resistant Polyurethane Foam

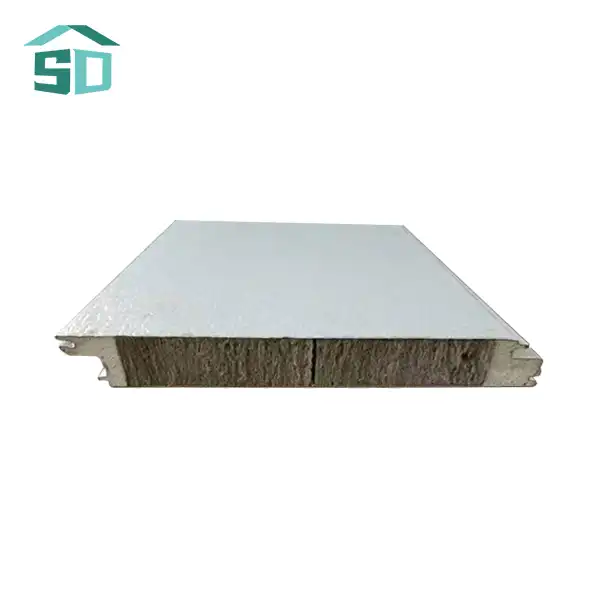

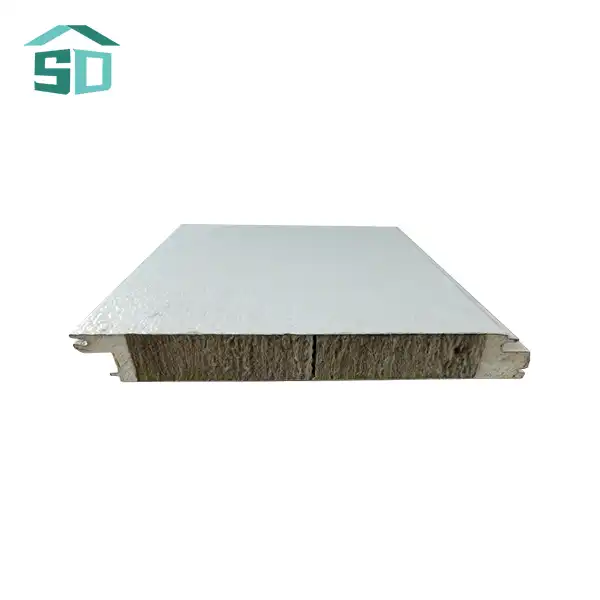

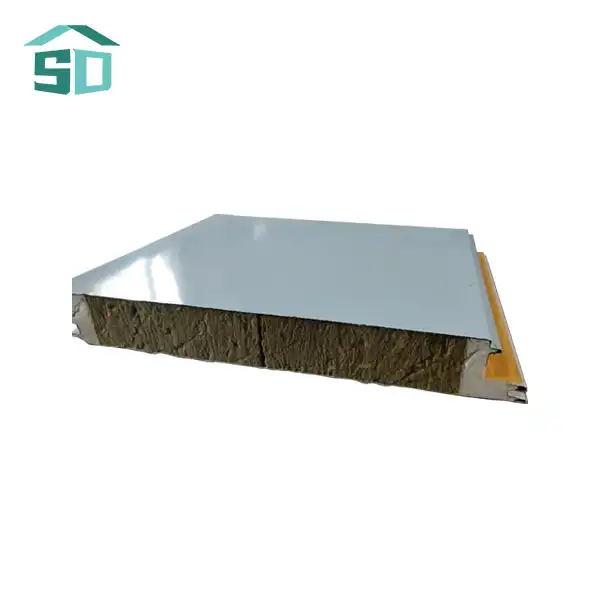

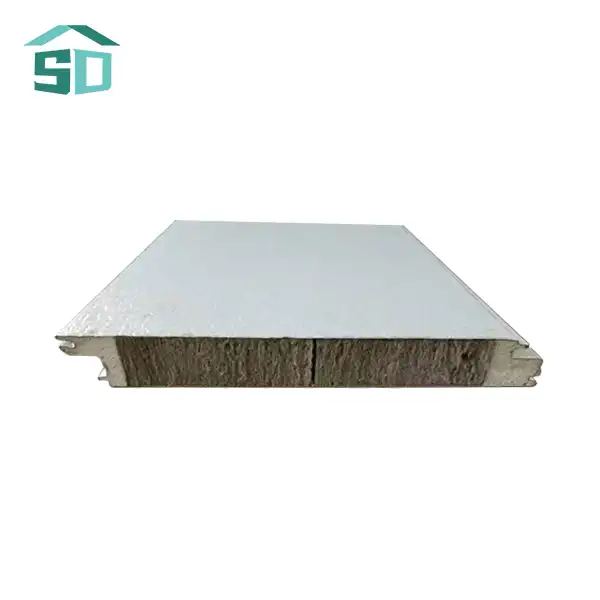

Polyurethane foam insulation panels have revolutionized the construction industry with their remarkable insulating properties. However, the addition of fire-resistant characteristics elevates their value exponentially. The fire resistance of these panels is achieved through a complex chemical process that involves incorporating flame retardants into the polyurethane foam during manufacturing.

These flame retardants work by interrupting the combustion process at various stages. Some act by forming a dense, protective char layer when exposed to high temperatures, effectively insulating the underlying material and slowing heat penetration. Others release non-flammable gases, such as water vapor or carbon dioxide, that dilute combustible gases in the surrounding area, thereby suppressing flames. This multi-faceted approach ensures panels not only resist ignition but also significantly delay fire spread, offering additional time for evacuation and emergency response.

Thermal Properties and Fire Performance

The thermal conductivity of fire-resistant polyurethane foam insulation panels is exceptionally low, typically ≤ 0.022 W/(m·K), ensuring minimal heat transfer through building envelopes. This outstanding insulating performance reduces dependence on heating and cooling systems, enabling long-term energy efficiency. Equally impressive is their fire performance, achieving a B1 fire rating according to strict European standards. This classification confirms that the panels contribute very little to fire growth, while minimizing smoke release and eliminating dangerous flaming droplets, ensuring safer conditions during fire events.

Applications and Benefits of Fire-Resistant Polyurethane Panels

Fire-resistant polyurethane foam insulation panels find applications across various sectors of the construction industry. Their versatility makes them suitable for both new constructions and renovation projects. In residential buildings, these panels are commonly used for exterior walls and roofing, providing a robust thermal envelope that enhances energy efficiency while bolstering fire safety.

Commercial and industrial spaces benefit greatly from the use of these panels. Warehouses, factories, and logistics hubs employ them to improve both fire safety and insulation performance. Cold storage facilities, in particular, rely on their ability to maintain strict temperature control while resisting fire hazards. Due to their lightweight construction, they can be transported and installed quickly, reducing project timelines significantly. Their adaptability to modular construction further increases their appeal, as they provide consistent quality, reliable performance, and compliance with international safety regulations in diverse environments.

Cost-Effectiveness and Long-Term Value

Although the upfront cost of fire-resistant polyurethane foam panels may be higher than conventional alternatives, their long-term benefits far outweigh the investment. Their superior thermal insulation helps reduce utility bills for decades, directly lowering operational costs. Furthermore, their fire-resistant nature reduces risks of catastrophic losses, potentially lowering insurance premiums for property owners. By slowing fire spread and minimizing structural damage, these panels not only safeguard lives but also protect valuable assets. This enhanced safety profile provides long-term financial benefits, making them a highly cost-effective investment choice. With a service life that often exceeds 25 years under proper maintenance, these panels deliver outstanding returns by combining safety, efficiency, and durability, making them a highly cost-effective choice for developers and building owners.

Installation and Maintenance Considerations

Proper installation of fire-resistant polyurethane foam insulation panels is crucial to maximize their performance and ensure compliance with building codes. The installation process typically involves preparing the surface, cutting the panels to size, applying adhesive, and securing the panels in place. Special attention must be paid to sealing joints and edges to maintain the continuity of the fire-resistant barrier and prevent thermal bridging.

Maintenance of these panels is relatively straightforward and does not require extensive effort compared to many traditional materials. Regular inspections should be scheduled to identify cracks, dents, or surface wear that may reduce their efficiency. Although the panels are designed to resist moisture, pests, and weathering, proper ventilation and immediate response to any signs of water ingress are vital for long-term performance. Care should also be taken during renovations to avoid punctures, as damage may compromise both insulation and fire resistance.

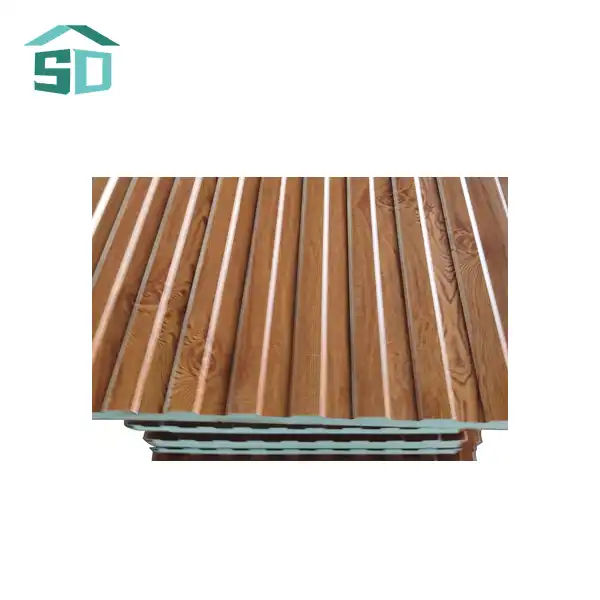

Customization and Aesthetic Options

Fire-resistant polyurethane foam panels are designed with flexibility in mind, offering various thicknesses ranging from 50mm to 150mm to match specific insulation requirements. Surface finishes are highly customizable, including smooth, embossed, or textured designs that blend with different architectural themes. They can also be coated in diverse colors, from neutral shades to vibrant tones, enabling both functional and aesthetic goals to be met. This adaptability allows architects and designers to prioritize safety and efficiency while still achieving modern, attractive facades or unique visual expressions.

Conclusion

Fire-resistant polyurethane foam insulation panels represent a significant advancement in building materials technology. They offer an unparalleled combination of thermal efficiency, fire safety, and durability, making them an ideal choice for a wide range of construction projects. As the construction industry continues to prioritize energy efficiency and safety, these panels are poised to play an increasingly important role in shaping the buildings of the future.

At Weifang Sandong Building Materials Co., Ltd., we are committed to providing high-quality fire-resistant polyurethane foam insulation panels that meet the highest standards of performance and safety. Our panels are designed to offer superior insulation, fire resistance, and longevity, helping you create safer, more energy-efficient buildings. To learn more about our products or to request a sample, please contact us at info@sdqsc.com.

FAQ

How do fire-resistant polyurethane foam insulation panels compare to traditional insulation materials?

Fire-resistant polyurethane foam panels offer superior thermal insulation and fire resistance compared to traditional materials. They have a lower thermal conductivity and higher fire rating, providing better energy efficiency and safety.

Are these panels environmentally friendly?

Yes, our panels are made from environmentally friendly materials and contribute to sustainable building practices by significantly reducing energy consumption in buildings.

Can these panels be used in both residential and commercial buildings?

Absolutely. Fire-resistant polyurethane foam insulation panels are versatile and suitable for various applications, including residential, commercial, and industrial buildings.

What is the installation process like?

Installation is straightforward, involving surface preparation, cutting, adhesive application, and secure mounting. We provide comprehensive installation guidelines and technical support.

References

1.European Committee for Standardization. (2020). EN 13501-1: Fire classification of construction products and building elements.

2.International Code Council. (2021). International Building Code.

3.U.S. Department of Energy. (2022). Insulation Materials.

4.American Society for Testing and Materials. (2021). ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials.