The Evolution of Green Thermal Insulation Technology

Advancements in Eco-Friendly Materials

The journey of green thermal insulation panels began with a vision to create sustainable building solutions. Over the years, manufacturers have made significant strides in developing eco-friendly materials that offer superior insulation properties. These advancements have led to the creation of panels that not only provide excellent thermal performance but also contribute to a healthier planet.

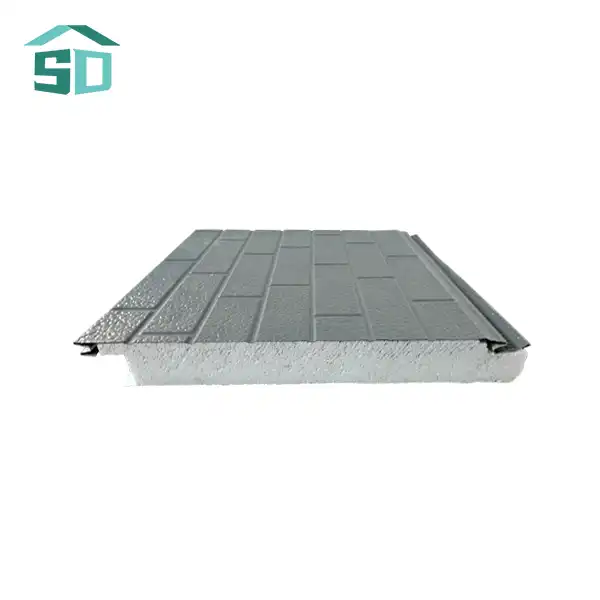

Green thermal insulation panels now incorporate a range of innovative materials, including recycled polyurethane, polystyrene, rock wool, and glass wool. These materials are chosen for their exceptional insulation properties and their ability to be recycled at the end of their life cycle. By utilizing these eco-friendly options, manufacturers have significantly reduced the environmental impact of insulation production.

Customization and Versatility

One of the key features of modern green thermal insulation panels is their high degree of customizability. Leading manufacturers provide panels in a wide range of sizes, thicknesses, and finishes, enabling architects and builders to meet diverse design and functional requirements. This flexibility allows energy-efficient buildings to be constructed without compromising aesthetic appeal, ensuring that the panels seamlessly integrate with the architectural vision while delivering superior thermal performance and sustainability benefits.

The thickness of green thermal insulation panels generally ranges from 50mm to 200mm, offering precise control over thermal insulation for different climatic conditions. In addition to their performance benefits, these panels can be coated, painted, or anodized in various colors, enhancing the visual appeal of the building. This combination of customizable dimensions and finishes ensures that the panels provide both energy efficiency and architectural versatility, making them suitable for a wide variety of construction projects and design requirements.

Environmental Benefits of Green Thermal Insulation Panels

Energy Efficiency and Carbon Footprint Reduction

The primary environmental benefit of green thermal insulation panels lies in their ability to significantly enhance energy efficiency in buildings. By providing superior insulation, these panels help maintain consistent indoor temperatures, reducing the need for heating and cooling systems to work overtime. This translates to lower energy consumption and, consequently, a reduced carbon footprint for the building.

Studies have shown that buildings equipped with high-quality green thermal insulation panels can achieve energy savings of up to 40% compared to those with traditional insulation methods. This not only benefits the environment but also leads to substantial cost savings for building owners and occupants.

Sustainable Manufacturing Processes

The production of green thermal insulation panels has become increasingly sustainable over the years. Manufacturers are adopting eco-friendly practices throughout the production process, from sourcing raw materials to the final assembly of panels.

Many green thermal insulation panel manufacturers now use renewable energy sources in their production facilities, further reducing the environmental impact of these products. Additionally, the use of recycled materials in panel production helps conserve natural resources and reduce waste.

Recycled Content and End-of-Life Considerations

Incorporation of Recycled Materials

A significant aspect of green thermal insulation panels is their extensive use of recycled content, which enhances their sustainability profile. Many leading manufacturers now incorporate recycled aluminum and steel in the outer layers of the panels, significantly reducing the need for virgin raw materials. Additionally, the insulation cores—particularly those made from glass wool or rock wool—often contain a high proportion of recycled fibers. This approach not only conserves natural resources but also supports environmentally responsible production and lowers the overall carbon footprint of the panels.

By using recycled materials, green thermal insulation panels help divert waste from landfills and reduce the energy required for raw material extraction and processing. This circular manufacturing approach ensures that the materials remain in use for as long as possible, promoting sustainability across the building lifecycle. Such practices align with global initiatives for greener construction, reducing environmental impact while maintaining high thermal performance, structural integrity, and long-term durability in diverse building applications.

End-of-Life Recyclability

The environmental impact of green thermal insulation panels goes well beyond their active use in buildings. They are specifically designed with end-of-life considerations, allowing for recycling or repurposing when a building is renovated or demolished. This approach supports sustainable construction practices and reduces the ecological footprint of the built environment.

The metal components of these panels, such as aluminum and steel, are fully recyclable and can be reprocessed into new industrial or construction products. Depending on their composition, the insulation materials can also be recycled or repurposed for other applications. This emphasis on recyclability helps minimize waste, conserve resources, and promote a circular economy in building materials.

Conclusion

Green thermal insulation panels represent a significant step forward in sustainable building practices. Their combination of energy efficiency, recycled content, and recyclability makes them an environmentally responsible choice for modern construction. As technology continues to advance, we can expect even more innovative and eco-friendly solutions in the realm of building insulation.

For those looking to incorporate these sustainable solutions into their projects, Weifang Sandong Building Materials Co., Ltd. offers a range of high-quality green thermal insulation panels. As a leading green thermal insulation panels manufacturer, we are committed to providing eco-friendly products that meet the highest standards of performance and sustainability. To learn more about our products and how they can benefit your next project, please contact us at info@sdqsc.com.

FAQs

What makes green thermal insulation panels environmentally friendly?

These panels are made from recyclable materials, offer superior energy efficiency, and can be recycled at the end of their life cycle.

How do green thermal insulation panels compare to traditional insulation in terms of performance?

They typically offer better insulation properties, leading to higher energy savings and improved temperature control in buildings.

Are green thermal insulation panels suitable for all types of buildings?

Yes, they can be used in residential, commercial, and industrial buildings, offering versatility in application.

What is the typical lifespan of green thermal insulation panels?

With proper installation and maintenance, these panels can last for several decades, contributing to their overall sustainability.

References

1.International Energy Agency. (2021). "Buildings: A source of enormous untapped efficiency potential." IEA, Paris.

2.U.S. Department of Energy. (2022). "Insulation Materials." Energy Saver.

3.European Commission. (2020). "Energy efficiency in buildings." Energy.

4.World Green Building Council. (2019). "Bringing embodied carbon upfront." WorldGBC.