Grasping Fire Resistance Ratings in Prefabricated Thermal Panels

Fire resistance ratings play a crucial role in determining the safety of building materials, including prefabricated thermal panels. These ratings indicate how long a material can withstand exposure to fire while maintaining its structural integrity and insulation properties. For prefabricated thermal panels, fire resistance is measured through rigorous testing procedures that simulate real-world fire scenarios.

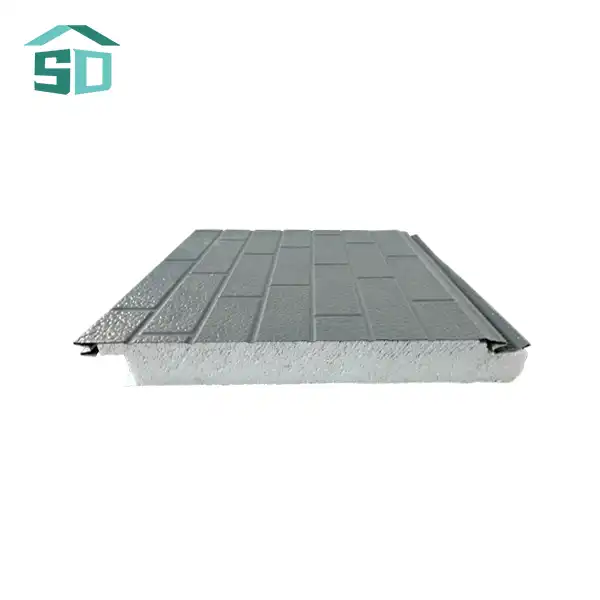

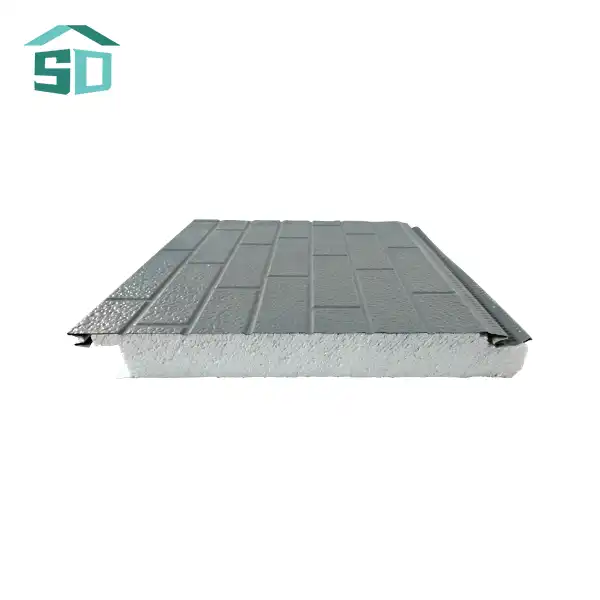

The fire resistance of prefabricated thermal panels is influenced by several factors, including the type of core material used, the thickness of the panels, and the composition of the outer facings. Manufacturers like Weifang Sandong Building Materials Co., Ltd. utilize advanced materials and production techniques to enhance the fire-resistant properties of their panels.

Core Materials and Their Impact on Fire Resistance

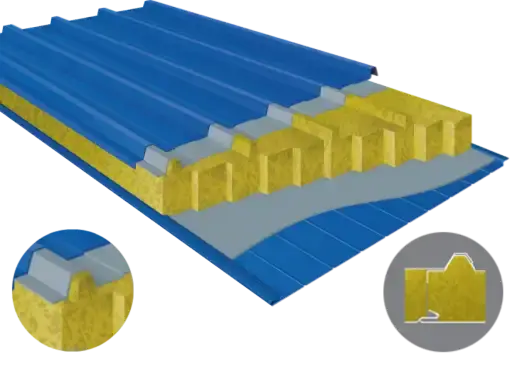

The core material of prefabricated thermal panels significantly affects their fire resistance capabilities. Common core materials include:

- Polyurethane (PUR): Offers good insulation properties but requires additional fire-retardant treatments.

- Polyisocyanurate (PIR): Provides improved fire resistance compared to PUR.

- Mineral Wool: Inherently non-combustible and offers excellent fire resistance.

- Glass Wool: Another non-combustible option with high fire resistance ratings.

Each core material undergoes specific treatments and modifications to enhance its fire-resistant properties, ensuring that the prefabricated thermal panels meet or exceed industry standards for fire safety.

Testing Standards for Fire Resistance

Prefabricated thermal panels undergo rigorous testing to determine their fire resistance ratings. These tests typically involve exposing the panels to controlled fire conditions and measuring their performance over time. Some key testing standards include:

- ASTM E119: Standard Test Methods for Fire Tests of Building Construction and Materials

- EN 13501-1: Fire classification of construction products and building elements

- ISO 834: Fire-resistance tests

- Elements of building construction

These standardized tests evaluate factors such as flame spread, smoke development, and structural integrity under fire conditions. The results of these tests determine the fire resistance rating assigned to the prefabricated thermal panels, with higher ratings indicating superior fire protection capabilities.

Enhancing Building Safety with Fire-Resistant Prefabricated Thermal Panels

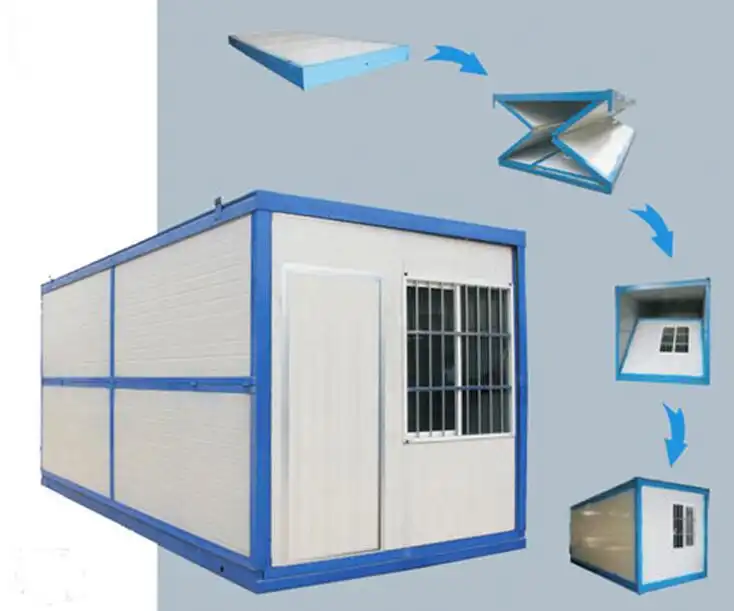

The incorporation of fire-resistant prefabricated thermal panels in building design significantly enhances overall safety. These panels not only provide excellent insulation but also act as a critical barrier against fire propagation. By choosing panels with high fire resistance ratings, architects and builders can create structures that offer improved protection for occupants and assets.

Benefits of Fire-Resistant Prefabricated Thermal Panels

Fire-resistant prefabricated thermal panels offer numerous advantages in terms of building safety:

- Delayed Fire Spread: The panels slow down the progression of fire through a building, providing crucial time for evacuation and emergency response.

- Reduced Smoke Generation: Many fire-resistant panels are designed to minimize smoke production, which is often more dangerous than the flames themselves.

- Structural Integrity: High-quality panels maintain their form and function even when exposed to high temperatures, helping to preserve the building's structural stability.

- Comprehensive Protection: These panels offer a combination of thermal insulation and fire resistance, addressing multiple safety concerns simultaneously.

By incorporating these benefits into building design, architects and engineers can create safer, more resilient structures that better protect occupants and valuable assets.

Integration with Fire Safety Systems

Fire-resistant prefabricated thermal panels work in conjunction with other fire safety systems to provide comprehensive protection. When integrated with sprinkler systems, smoke detectors, and fire alarms, these panels contribute to a holistic approach to fire safety. The panels' ability to compartmentalize fires and maintain structural integrity complements active fire suppression measures, creating a multi-layered defense against fire-related hazards.

Real-World Performance and Case Studies

The true test of fire-resistant prefabricated thermal panels lies in their real-world performance. Numerous case studies and incident reports have demonstrated the effectiveness of these panels in actual fire scenarios. Buildings equipped with high-quality, fire-resistant panels have shown improved outcomes in terms of fire containment, reduced property damage, and enhanced occupant safety.

Notable Incidents and Outcomes

Several documented cases highlight the performance of fire-resistant prefabricated thermal panels:

- Industrial Facility Fire (2018): A manufacturing plant with fire-resistant panels experienced a localized fire that was successfully contained within a single section, preventing widespread damage.

- High-Rise Office Building (2020): During a fire outbreak on the 15th floor, the building's fire-resistant panels helped limit the spread of flames, allowing for a safe and orderly evacuation.

- Residential Complex (2019): A multi-unit housing development constructed with fire-resistant panels demonstrated superior fire containment, minimizing damage to adjacent units during a kitchen fire incident.

These examples underscore the practical benefits of investing in high-quality, fire-resistant prefabricated thermal panels for various types of structures.

Ongoing Research and Development

The field of fire-resistant building materials, including prefabricated thermal panels, is subject to continuous research and development. Manufacturers and research institutions are constantly working to improve the fire resistance properties of these panels, exploring new materials, coatings, and design techniques to enhance their performance.

Recent advancements include:

- Nano-engineered coatings that provide enhanced fire protection

- Hybrid core materials that combine the benefits of different insulation types

- Improved panel joint designs that minimize weak points in fire resistance

These ongoing innovations promise to further improve the safety and performance of prefabricated thermal panels in fire scenarios, making them an increasingly valuable component of modern, safety-conscious building design.

Conclusion

Prefabricated thermal panels have proven to be remarkably safe and effective in enhancing fire resistance in buildings. Their advanced engineering, rigorous testing, and real-world performance demonstrate their capability to significantly improve building safety. By slowing fire spread, reducing smoke generation, and maintaining structural integrity, these panels provide crucial protection in fire scenarios. As research and development continue, we can expect even more innovative and effective fire-resistant solutions in the future, further solidifying the role of prefabricated thermal panels in modern construction.

Are you looking to enhance the fire safety of your next construction project? Weifang Sandong Building Materials Co., Ltd. offers state-of-the-art prefabricated thermal panels that combine superior insulation with top-tier fire resistance. Our panels are customizable to meet your specific project needs, ensuring both safety and efficiency. Contact us at info@sdqsc.com to learn more about how our innovative panels can elevate your building's fire safety standards while providing unmatched thermal performance.

FAQ

What makes prefabricated thermal panels fire-resistant?

The fire resistance of these panels comes from their non-combustible materials, specially designed cores, and fire-retardant treatments.

How long can prefabricated thermal panels withstand fire?

The duration depends on the panel's fire rating, which can range from 30 minutes to several hours for high-performance panels.

Are all prefabricated thermal panels equally fire-resistant?

No, fire resistance varies based on materials, thickness, and design. It's important to check the specific fire rating of the panels you're considering.

Can prefabricated thermal panels be used in high-rise buildings?

Yes, many high-rise buildings use fire-resistant prefabricated thermal panels to meet stringent safety requirements.

References

1. National Fire Protection Association. (2021). NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components.

2. International Code Council. (2021). International Building Code.

3. Underwriters Laboratories. (2020). UL 263: Standard for Fire Tests of Building Construction and Materials.

4. European Committee for Standardization. (2019). EN 13501-1: Fire classification of construction products and building elements.

5. International Organization for Standardization. (2019). ISO 834: Fire-resistance tests - Elements of building construction.