The Revolutionary Structure of Aluminium Insulated Sandwich Panels

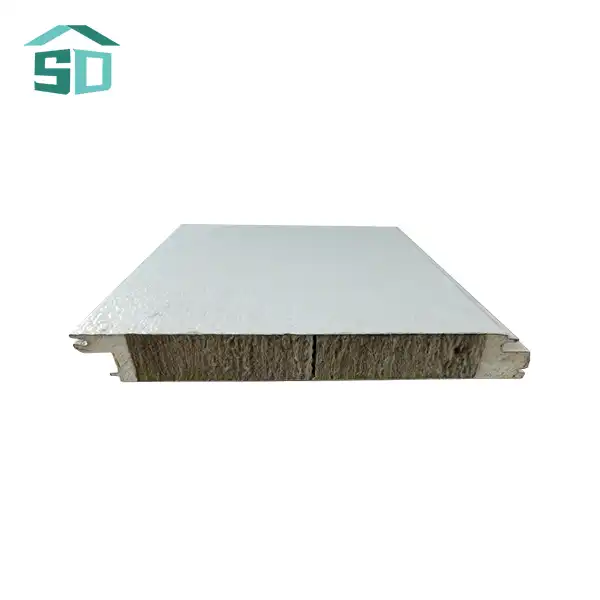

Core Composition: The Heart of Insulation and Strength

At the core of Aluminium Insulated Sandwich Panels lies a sophisticated blend of materials that contribute to their exceptional performance. The aluminium core, typically composed of a lightweight yet sturdy foam, serves as the primary insulating layer. This core is meticulously engineered to provide optimal thermal resistance, effectively minimizing heat transfer between interior and exterior environments.

The density and composition of this core are carefully calibrated to achieve the desired balance between insulation properties and structural integrity, ensuring that the panels can withstand various loads and environmental stresses without compromising their insulative qualities.

Surrounding this core are two metal sheets, often made of high-grade aluminium or steel, which are bonded to the insulation material. These outer layers not only provide a smooth, aesthetically pleasing surface but also act as a protective barrier against external elements. The bonding process between the core and the metal sheets is crucial, utilizing advanced adhesive technologies to create a seamless, unified panel that resists delamination and maintains its structural integrity over time.

Thermal Efficiency: Advanced Insulation for Energy Conservation

The thermal efficiency of Aluminium Insulated Sandwich Panels is one of their most notable attributes, setting them apart in the realm of building materials. The insulative core, often composed of polyurethane or polyisocyanurate foam, boasts impressive R-values, indicating superior resistance to heat flow.

This high level of insulation translates to significant energy savings for buildings, as it reduces the workload on heating and cooling systems. In warm climates, the panels effectively block heat ingress, maintaining cooler interior temperatures, while in colder regions, they prevent heat escape, ensuring warmth is retained within the building envelope.

Moreover, the thermal performance of these panels extends beyond mere insulation. The reflective properties of the aluminium surfaces contribute to the overall energy efficiency by reflecting a portion of solar radiation, further reducing heat gain in sun-exposed areas. This multifaceted approach to thermal management makes Aluminium Insulated Sandwich Panels an excellent choice for projects aiming to meet or exceed energy efficiency standards and sustainability goals.

Versatility and Aesthetic Appeal in Design Applications

Customizable Aesthetics: Tailoring Panels to Architectural Visions

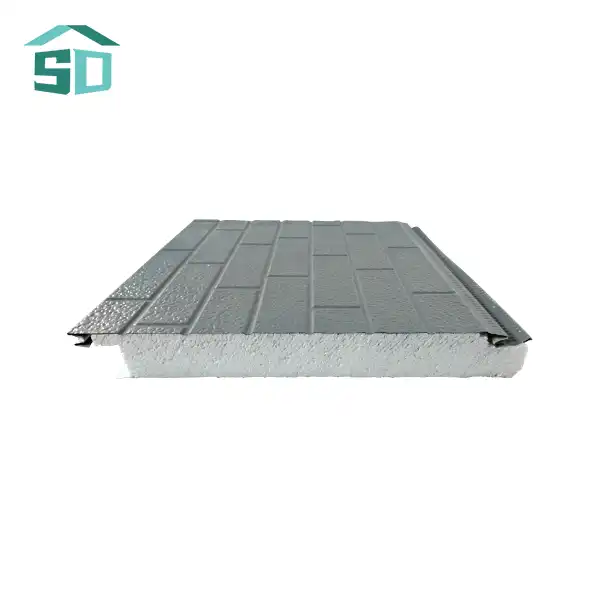

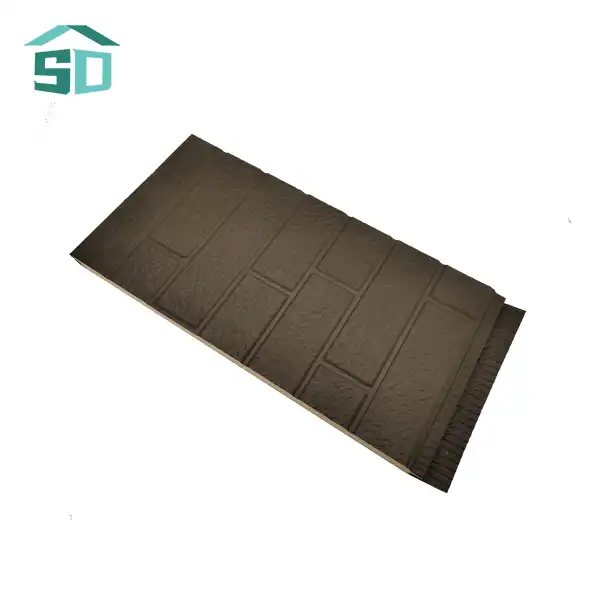

The adaptability of Aluminium Insulated Sandwich Panels in terms of aesthetics is a key factor in their growing popularity among architects and designers. These panels offer an extensive range of customization options, allowing for the creation of unique and visually striking facades. The outer metal sheets can be finished in a vast array of colors, textures, and patterns, providing architects with the flexibility to realize their creative visions without compromising on functionality.

Beyond color and texture, these panels can be fabricated in various shapes and sizes, enabling the creation of complex geometric patterns and three-dimensional effects on building exteriors. This versatility allows for the seamless integration of the panels into diverse architectural styles, from contemporary minimalist designs to more traditional or eclectic aesthetics.

Additionally, the panels can be perforated or embossed to create unique visual textures and light effects, further expanding their design potential. This level of customization ensures that Aluminium Insulated Sandwich Panels can serve not just as functional building components but as integral elements of architectural expression.

Versatile Application: Interior and Exterior Solutions

While Aluminium Insulated Sandwich Panels are widely recognized for their use in exterior cladding, their versatility extends to interior applications as well. In exterior settings, these panels excel in creating weather-resistant, energy-efficient building envelopes. They are particularly well-suited for large commercial structures, industrial facilities, and modern residential buildings, where their combination of aesthetic appeal and functional benefits can be fully leveraged.

Internally, these panels offer innovative solutions for partition walls, ceiling systems, and decorative elements. Their lightweight nature and ease of installation make them an attractive option for creating flexible, reconfigurable spaces in commercial and institutional settings. The panels' excellent acoustic properties also contribute to improved sound insulation between rooms, enhancing privacy and comfort in multi-use spaces.

Durability and Safety: Meeting Modern Construction Demands

Fire Safety and Building Code Compliance

In the realm of building materials, fire safety is of paramount importance, and Aluminium Insulated Sandwich Panels are engineered to meet stringent fire safety standards. Many variants of these panels incorporate fire-resistant cores and surface treatments that significantly retard flame spread and smoke development. This inherent fire resistance is crucial in ensuring building occupants have adequate time for evacuation in the event of a fire. Manufacturers often subject their panels to rigorous testing procedures, including full-scale fire tests, to verify their performance under real-world fire conditions.

Compliance with building codes is another critical aspect where Aluminium Insulated Sandwich Panels excel. These panels are typically designed and manufactured to meet or exceed local and international building regulations, including those related to fire safety, structural integrity, and energy efficiency.

This compliance ensures that architects and builders can confidently incorporate these panels into their projects, knowing they meet the necessary legal and safety requirements. The ability of these panels to satisfy multiple building code criteria simultaneously – from thermal performance to fire resistance – simplifies the design and approval process, potentially leading to faster project completion times.

Corrosion Resistance and Longevity in Harsh Environments

The durability of Aluminium Insulated Sandwich Panels in challenging environmental conditions is a testament to their advanced engineering and material composition. The aluminium outer layers of these panels naturally form a protective oxide layer when exposed to air, providing an inherent defense against corrosion.

This characteristic makes them particularly suitable for use in coastal areas or industrial environments where exposure to salt spray or corrosive chemicals is a concern. Many manufacturers further enhance this corrosion resistance through the application of specialized coatings or treatments, ensuring the panels maintain their structural integrity and appearance over extended periods.

The longevity of these panels translates into significant benefits for building owners and operators. Their resistance to weathering, UV radiation, and temperature fluctuations means they require minimal maintenance over their lifespan, reducing long-term operational costs. This durability also contributes to the sustainability of buildings, as the need for frequent replacements or repairs is greatly reduced.

Conclusion

Aluminium Insulated Sandwich Panels represent a remarkable fusion of form and function in modern construction materials. Their unique combination of strength, thermal efficiency, design flexibility, and durability positions them as an ideal solution for a wide range of architectural applications.

For those seeking to explore the potential of Aluminium Insulated Sandwich Panels in their projects, Weifang Sandong Building Materials Co., Ltd. stands ready to provide expert guidance and high-quality products. To learn more about our exterior cladding and facade solutions, please contact us at info@sdqsc.com.