Understanding PUF Sandwich Panels: Composition and Benefits

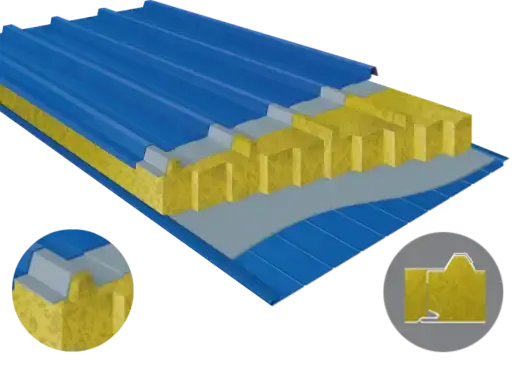

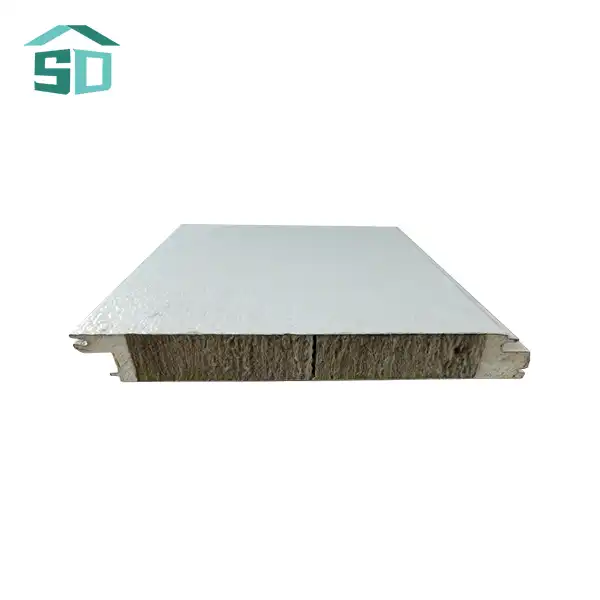

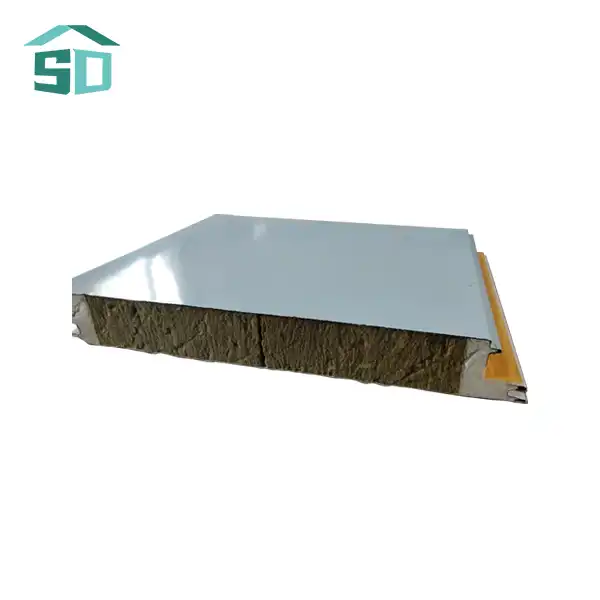

PUF sandwich panels, also known as polyurethane foam sandwich panels, are composite materials that have revolutionized the construction industry. These panels consist of three primary components: two outer facing sheets typically made of steel, aluminum, or stainless steel, and a core of rigid polyurethane foam. This unique structure contributes to the panels' exceptional strength-to-weight ratio and insulation properties.

The Anatomy of PUF Sandwich Panels

The outer facing sheets of PUF sandwich panels provide structural integrity and serve as a barrier against external elements. These metal sheets can be customized in terms of thickness, color, and surface treatment to meet specific project requirements. The heart of the panel, the polyurethane foam core, is responsible for its impressive insulation capabilities. This foam is created through a chemical reaction that produces a closed-cell structure, which is key to its performance against moisture and temperature fluctuations.

Advantages of PUF Sandwich Panels in Construction

PUF sandwich panels offer a myriad of benefits that make them an attractive option for various construction applications. Their lightweight nature facilitates easy handling and installation, reducing labor costs and construction time. Despite their light weight, these panels boast remarkable strength and rigidity, making them suitable for both load-bearing and non-load-bearing applications.

The superior thermal insulation provided by the polyurethane foam core contributes to energy efficiency in buildings, helping to maintain comfortable indoor temperatures while reducing heating and cooling costs. Additionally, PUF sandwich panels exhibit excellent sound absorption properties, enhancing acoustic comfort in various settings.

PUF Sandwich Panels vs. Moisture: A Battle of Resilience

Moisture is a pervasive threat in construction, capable of compromising structural integrity and fostering mold growth. PUF sandwich panels, however, are engineered to resist moisture intrusion and its detrimental effects.

Moisture Resistance Mechanisms in PUF Sandwich Panels

The closed-cell structure of the polyurethane foam core in PUF sandwich panels plays a crucial role in moisture resistance. Unlike open-cell foams, closed-cell polyurethane foam contains tiny pockets of air or gas that are completely sealed off from one another. This structure significantly impedes water vapor transmission and liquid water penetration.

Furthermore, the metal facing sheets of PUF sandwich panels provide an additional barrier against moisture. When properly installed with sealed joints and appropriate flashing, these panels create a highly effective moisture barrier for buildings.

Long-term Performance in High-Humidity Environments

PUF sandwich panels have demonstrated excellent long-term performance in high-humidity environments. The inherent moisture resistance of the polyurethane foam core helps maintain the panel's insulation properties and structural integrity even when exposed to persistent high humidity levels.

It's worth noting that while PUF sandwich panels are highly resistant to moisture, proper installation and maintenance are crucial for optimal performance. Ensuring proper sealing of joints and regular inspections can further enhance the panels' ability to withstand moisture-related challenges over time.

Corrosion Resistance: PUF Sandwich Panels' Line of Defense

Corrosion is a significant concern in construction, particularly for metal components exposed to environmental factors. PUF sandwich panels, with their metal facing sheets, must contend with this challenge. However, these panels are designed with corrosion resistance in mind, incorporating several features to protect against degradation.

Protective Coatings and Surface Treatments

The metal facing sheets of PUF sandwich panels are typically treated with protective coatings or undergo surface treatments to enhance their corrosion resistance. Common treatments include galvanization for steel sheets, which involves applying a zinc coating to protect the underlying metal. For aluminum facing sheets, anodizing is often employed to create a hard, durable oxide layer that resists corrosion.

Additionally, many PUF sandwich panel manufacturers offer a range of specialized coatings designed for specific environmental conditions. These may include polyester, PVDF (polyvinylidene fluoride), or other high-performance coatings that provide superior protection against corrosion, UV radiation, and chemical exposure.

The Role of the Polyurethane Core in Corrosion Prevention

While the outer metal sheets are the primary defense against corrosion, the polyurethane foam core of PUF sandwich panels also contributes to corrosion resistance. The closed-cell structure of the foam helps prevent moisture from reaching the inner surface of the metal facing sheets, reducing the risk of internal corrosion.

Moreover, the adhesive bonding between the foam core and the metal sheets creates a barrier that further protects against moisture intrusion and potential corrosion initiation points.

Conclusion

PUF sandwich panels have proven to be a durable and resilient solution in the face of moisture and corrosion challenges. Their unique composition, combining metal facing sheets with a polyurethane foam core, creates a synergistic structure that offers superior protection against environmental factors. The closed-cell foam core provides excellent moisture resistance, while specialized coatings and treatments enhance the corrosion resistance of the metal sheets. As the construction industry continues to evolve, PUF sandwich panels stand as a testament to innovative materials that prioritize durability without compromising on performance or aesthetics.

Are you considering PUF sandwich panels for your next construction project? Weifang Sandong Building Materials Co., Ltd. offers a wide range of high-quality PUF sandwich panels tailored to meet diverse architectural needs. Our panels are designed to withstand the rigors of various environments while providing superior insulation and aesthetic appeal. Contact us at info@sdqsc.com to learn more about how our PUF sandwich panels can enhance the durability and efficiency of your building.

FAQs

What is the typical lifespan of PUF sandwich panels?

PUF sandwich panels, when properly installed and maintained, can last 30-50 years or more, depending on environmental conditions and usage.

Can PUF sandwich panels be used in coastal areas with high salt exposure?

Yes, with appropriate coatings and treatments, PUF sandwich panels can be suitable for coastal environments. Special considerations may be necessary for extreme conditions.

How do PUF sandwich panels compare to traditional building materials in terms of durability?

PUF sandwich panels often outperform traditional materials in terms of insulation, moisture resistance, and overall durability, especially in challenging environments.

Are there any special maintenance requirements for PUF sandwich panels?

Regular inspections and cleaning are recommended. Specific maintenance needs may vary based on the panel type and environmental conditions.

References

1. Davies, J.M. (2001). Lightweight sandwich construction. John Wiley & Sons.

2. Zenkert, D. (1997). The handbook of sandwich construction. Engineering Materials Advisory Services Ltd.

3. Ashby, M.F., & Brechet, Y.J.M. (2003). Designing hybrid materials. Acta materialia, 51(19), 5801-5821.

4. Bitzer, T. (1997). Honeycomb technology: materials, design, manufacturing, applications and testing. Springer Science & Business Media.

5. Gibson, L.J., & Ashby, M.F. (1999). Cellular solids: structure and properties. Cambridge university press.