- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Corrugated vs. Flat Sandwich Panels: Which Is Right for You?

When it comes to choosing between corrugated and flat sandwich panels, the decision ultimately depends on your specific project requirements. Corrugated panels offer superior strength and load-bearing capacity, making them ideal for large-scale industrial and commercial applications. On the other hand, flat panels provide a sleek, modern aesthetic and are often preferred for residential and smaller commercial projects. Both types offer excellent insulation properties, but corrugated panels may have a slight edge in terms of durability and weather resistance. Consider factors such as building design, climate conditions, and budget to determine which option best suits your needs.

Understanding Sandwich Panels: A Comprehensive Guide

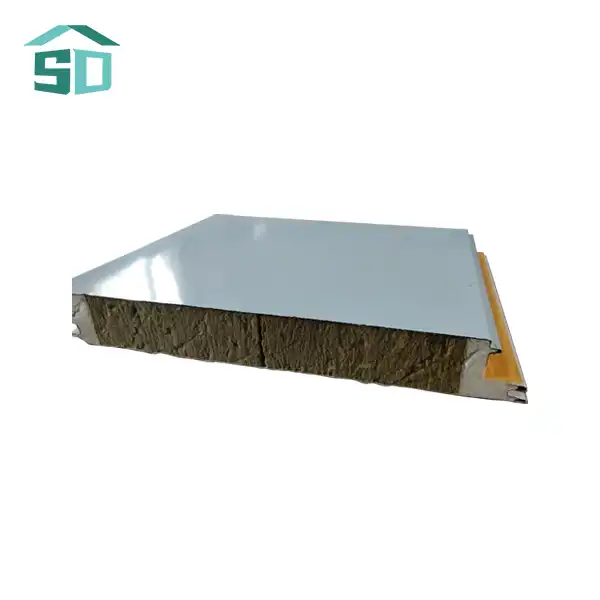

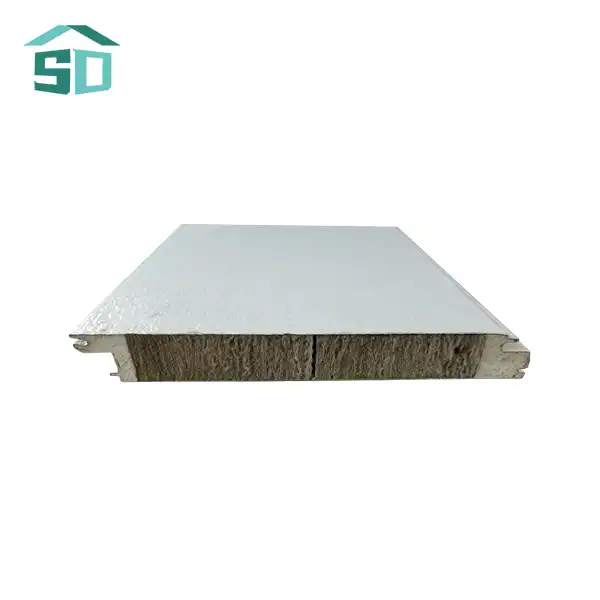

Sandwich panels are innovative building materials that have revolutionized the construction industry. These versatile panels consist of two outer layers, typically made of metal or other durable materials, with an insulating core sandwiched between them. This unique structure provides a combination of strength, insulation, and lightweight properties that make sandwich panels an attractive option for various applications.

The Anatomy of a Sandwich Panel

To fully appreciate the benefits of sandwich panels, it's essential to understand their composition. The outer layers, or skins, are usually made of materials like steel, aluminum, or fiberglass. These skins provide structural integrity and protection against external elements. The core, which is the heart of the panel, is typically composed of insulating materials such as polyurethane foam, expanded polystyrene, or mineral wool. This core is responsible for the panel's thermal and acoustic insulation properties.

Types of Sandwich Panels

There are several types of sandwich panels available in the market, each designed for specific applications. The two main categories we'll focus on are corrugated and flat sandwich panels. Corrugated panels feature a ribbed or wave-like surface on one or both sides, while flat panels have smooth, even surfaces. Other variations include insulated metal panels (IMPs), structural insulated panels (SIPs), and composite panels.

Applications of Sandwich Panels

Sandwich panels find applications in a wide range of industries and construction projects. They are commonly used in: - Industrial and commercial buildings - Cold storage facilities - Agricultural structures - Residential construction - Modular and prefabricated buildings - Transportation (e.g., truck bodies, marine vessels) - Aerospace industry

The versatility of sandwich panels makes them a popular choice for architects, builders, and property owners looking for efficient and cost-effective building solutions.

Corrugated Sandwich Panels: Strength and Durability

Corrugated sandwich panels are distinguished by their distinctive wave-like or ribbed surface. This unique design offers several advantages that make them particularly suitable for certain applications.

Structural Advantages of Corrugation

The corrugated profile of these panels provides enhanced structural strength and rigidity. The waves or ribs act as reinforcements, allowing the panels to span greater distances without additional support. This increased load-bearing capacity makes corrugated panels an excellent choice for roofing and wall cladding in large industrial and commercial buildings.

Weather Resistance and Durability

Corrugated sandwich panels offer superior weather resistance compared to their flat counterparts. The ribbed surface helps channel water and snow more effectively, reducing the risk of leaks and water damage. Additionally, the corrugated design provides better resistance to wind uplift, making these panels ideal for use in areas prone to high winds or severe weather conditions.

Thermal Performance

While the corrugated surface may slightly reduce the overall insulation value compared to flat panels, the difference is often negligible. Modern corrugated sandwich panels still offer excellent thermal performance, thanks to their insulating core. The slight reduction in insulation is often outweighed by the structural benefits and improved weather resistance.

Aesthetic Considerations

Corrugated sandwich panels have a distinct industrial appearance that can be either an advantage or a drawback, depending on the project's aesthetic requirements. While they may not be the first choice for sleek, modern designs, they can add character and visual interest to industrial and agricultural buildings.

Flat Sandwich Panels: Versatility and Modern Aesthetics

Flat sandwich panels, as the name suggests, feature smooth, even surfaces on both sides. This design offers its own set of advantages and makes them suitable for a different range of applications.

Sleek and Modern Appearance

The primary advantage of flat sandwich panels is their clean, contemporary appearance. The smooth surface provides a sleek, minimalist look that is highly desirable in modern architecture. This makes flat panels a popular choice for residential buildings, offices, and commercial spaces where aesthetics play a crucial role.

Versatility in Design

Flat sandwich panels offer greater flexibility in terms of finishes and colors. They can be easily painted or coated to match specific design requirements, and some manufacturers offer panels with pre-finished surfaces in a wide range of colors and textures. This versatility allows architects and designers to create unique and visually appealing facades.

Ease of Installation and Maintenance

The smooth surface of flat panels makes them easier to install and maintain compared to corrugated panels. They can be easily cleaned and don't trap dust or debris in the same way that ribbed surfaces do. This can lead to lower maintenance costs over the life of the building.

Thermal and Acoustic Performance

Flat sandwich panels often provide slightly better thermal insulation than their corrugated counterparts due to their uniform thickness. They also tend to offer superior acoustic performance, making them an excellent choice for applications where sound insulation is a priority, such as in residential buildings or office spaces.

Limitations of Flat Panels

While flat sandwich panels offer many advantages, they do have some limitations. They generally have lower load-bearing capacity compared to corrugated panels, which may necessitate additional structural support in some applications. They may also be more susceptible to visible dents or damage due to their smooth surface.

Conclusion

The choice between corrugated and flat sandwich panels ultimately depends on the specific requirements of your project. Corrugated panels excel in strength, durability, and weather resistance, making them ideal for large industrial and commercial applications. Flat panels, on the other hand, offer a sleek, modern appearance and greater design versatility, making them popular for residential and aesthetic-driven projects. Both types provide excellent insulation properties and can significantly enhance the energy efficiency of buildings. Consider factors such as structural requirements, climate conditions, aesthetic preferences, and budget when making your decision.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of choosing the right sandwich panels for your project. Our extensive range of high-quality insulation boards and sandwich panels caters to diverse construction needs. We're committed to providing innovative, efficient, and sustainable solutions that meet the highest standards of quality and performance. Whether you're looking for corrugated or flat sandwich panels, our team of experts is ready to help you make the best choice for your specific requirements. For personalized advice and top-quality sandwich panels, don't hesitate to contact us at info@sdqsc.com.

FAQ

What are the main differences between corrugated and flat sandwich panels?

Corrugated panels offer superior strength and weather resistance, while flat panels provide a sleek appearance and design versatility.

Which type of sandwich panel is best for industrial buildings?

Corrugated panels are generally preferred for industrial applications due to their higher load-bearing capacity and durability.

Are flat sandwich panels suitable for residential construction?

Yes, flat panels are often chosen for residential projects due to their modern aesthetic and excellent insulation properties.

How do sandwich panels contribute to energy efficiency?

The insulating core in sandwich panels significantly reduces heat transfer, improving the overall energy efficiency of buildings.

Can sandwich panels be customized for specific project requirements?

Yes, many manufacturers offer customization options in terms of size, thickness, core material, and surface finishes to meet specific project needs.

References

1.Cremer, K. (2018). Sandwich Panel Construction: Design and Applications. Springer.

2.Davies, J. M. (2001). Lightweight Sandwich Construction. John Wiley & Sons.

3.Wang, B., & Wu, L. (2016). Structural Analysis of Sandwich Panels. Elsevier.

4.National Roofing Contractors Association. (2020). The NRCA Roofing Manual: Metal Panel and SPF Roof Systems.

5.American Society for Testing and Materials. (2019). ASTM E72-15: Standard Test Methods of Conducting Strength Tests of Panels for Building Construction.