Grasping the Structural Differences Between Corrugated and Flat Sandwich Panels

To fully appreciate the thermal performance differences between corrugated and flat sandwich panels, it's crucial to understand their structural distinctions. Corrugated sandwich panels, as their name suggests, feature a wave-like pattern on their surface. This unique design is not merely aesthetic but serves a functional purpose in enhancing the panel's overall performance.

The Anatomy of a Corrugated Sandwich Panel

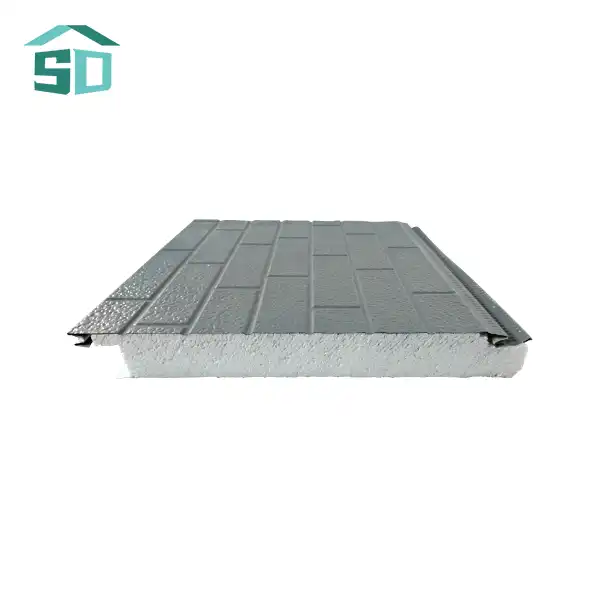

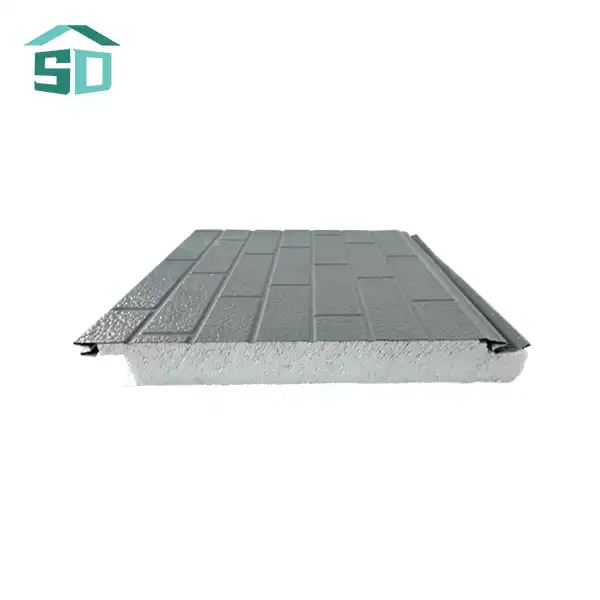

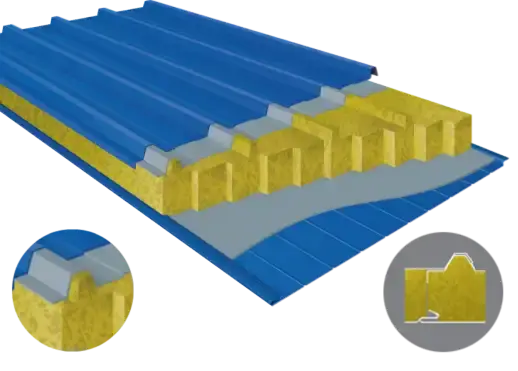

A corrugated sandwich panel consists of three main components: the outer facing, the inner facing, and the core material. The outer facing is typically made of metal, such as aluminum or steel, and features the distinctive corrugated pattern. This corrugation increases the panel's surface area and provides additional structural strength. The inner facing is usually flat and can be made of various materials, including metal or fiber-reinforced polymers. Between these two facings lies the core material, which is responsible for the panel's insulation properties.

Corrugated sandwich panel manufacturers often use high-performance insulation materials like polyurethane, polystyrene, or rock wool for the core. These materials are chosen for their excellent thermal resistance and ability to maintain their properties over time. The combination of the corrugated outer facing and the insulating core creates a panel that excels in both structural integrity and thermal performance.

The Structure of Flat Sandwich Panels

In contrast, flat sandwich panels have a simpler structure. They consist of two flat facings with an insulating core material sandwiched between them. While this design offers a sleek, modern appearance, it lacks the additional surface area and structural benefits provided by the corrugated design.

The flat structure does have some advantages, such as easier cleaning and a more uniform appearance. However, when it comes to thermal performance, the lack of corrugation can be a significant drawback. The flat surface provides less opportunity for heat dissipation and doesn't offer the same level of structural strength as its corrugated counterpart.

Thermal Performance Advantages of Corrugated Sandwich Panels

The unique structure of corrugated sandwich panels contributes significantly to their superior thermal performance. Let's delve into the specific advantages that make these panels a preferred choice for energy-efficient construction.

Enhanced Surface Area for Improved Heat Transfer

One of the primary reasons corrugated sandwich panels excel in thermal performance is their increased surface area. The wave-like pattern of the corrugated surface creates more space for heat exchange with the surrounding environment. This enhanced surface area allows for more efficient heat dissipation in warm conditions and better heat retention in cold environments.

Corrugated sandwich panel manufacturers leverage this property to create products that can significantly reduce a building's energy consumption. By facilitating more efficient heat transfer, these panels help maintain a stable internal temperature with less reliance on heating and cooling systems.

Improved Insulation Efficiency

The corrugated design not only increases surface area but also creates small air pockets within the panel structure. These air pockets act as additional insulation layers, further enhancing the panel's thermal performance. The combination of high-quality insulation materials in the core and these structural air pockets results in a panel with exceptional insulation properties.

This improved insulation efficiency translates to better temperature control within buildings, reducing the workload on HVAC systems and subsequently lowering energy costs. The corrugated sandwich panel's ability to maintain a consistent internal temperature makes it an ideal choice for various applications, from residential buildings to industrial facilities.

Structural Strength and Thermal Stability

The corrugated design of these sandwich panels doesn't just contribute to their thermal performance; it also enhances their structural integrity. The wave-like pattern provides additional rigidity and strength, allowing the panels to maintain their shape and insulation properties even under challenging conditions.

This structural stability is crucial for long-term thermal performance. Unlike flat panels that may warp or sag over time, corrugated sandwich panels are more likely to maintain their shape and continue providing optimal insulation throughout their lifespan. This durability ensures that the thermal performance of the building envelope remains consistent year after year.

Applications and Considerations for Corrugated Sandwich Panels

While the thermal performance advantages of corrugated sandwich panels are clear, it's essential to consider their applications and potential limitations when choosing between corrugated and flat options.

Ideal Applications for Corrugated Sandwich Panels

Corrugated sandwich panels are particularly well-suited for applications where energy efficiency and structural integrity are paramount. They excel in:

- Industrial and commercial buildings with large surface areas

- Cold storage facilities requiring superior insulation

- Agricultural structures exposed to varying weather conditions

- Residential buildings in extreme climates

- Renovation projects aimed at improving energy efficiency

In these applications, the thermal performance benefits of corrugated sandwich panels can lead to significant energy savings and improved comfort levels.Aesthetic Considerations and Customization Options

While the corrugated design offers functional benefits, some architects and property owners may prefer the sleek look of flat panels for aesthetic reasons. However, corrugated sandwich panel manufacturers have responded to this concern by offering a wide range of customization options.

Modern corrugated sandwich panels are available in various colors, patterns, and finishes, allowing for greater design flexibility. Some manufacturers even offer panels with subtler corrugation patterns that provide a balance between thermal performance and visual appeal. This versatility ensures that corrugated panels can be integrated into diverse architectural styles without compromising on aesthetics.

Installation and Maintenance Factors

When comparing corrugated and flat sandwich panels, it's also important to consider installation and maintenance requirements. Corrugated panels may require slightly more specialized installation techniques due to their unique shape. However, many corrugated sandwich panel manufacturers offer panels designed for easy installation, with interlocking systems that simplify the process.

In terms of maintenance, corrugated panels may require more attention to prevent debris accumulation in the grooves. However, this is often offset by their superior durability and resistance to environmental factors. The structural strength of corrugated panels can lead to fewer repairs and replacements over time, potentially reducing long-term maintenance costs.

Conclusion

In the comparison of thermal performance between corrugated and flat sandwich panels, corrugated options clearly emerge as the superior choice. Their unique structure provides enhanced surface area for improved heat transfer, better insulation efficiency, and greater structural stability. These advantages translate to significant energy savings and improved comfort in a wide range of applications. While flat panels may offer certain aesthetic benefits, the thermal performance of corrugated sandwich panels makes them an ideal solution for energy-efficient construction projects.

At Weifang Sandong Building Materials Co., Ltd., we specialize in manufacturing high-quality corrugated sandwich panels that combine excellent thermal performance with aesthetic appeal. Our panels are customizable to suit various architectural styles and are designed for easy installation and long-term durability. Whether you're planning a new construction project or looking to improve the energy efficiency of an existing structure, our corrugated sandwich panels offer an ideal solution. For more information about our products and how they can benefit your project, please contact us at info@sdqsc.com.

FAQ

Are corrugated sandwich panels more expensive than flat panels?

Initially, corrugated panels may have a slightly higher cost due to their complex structure. However, their superior thermal performance and durability often result in long-term cost savings through reduced energy consumption and maintenance needs.

Can corrugated sandwich panels be used for interior walls?

While primarily used for exterior applications, corrugated sandwich panels can be adapted for interior use, especially in industrial or commercial settings where thermal insulation is crucial.

How long do corrugated sandwich panels typically last?

With proper installation and maintenance, high-quality corrugated sandwich panels can last 30 years or more, maintaining their thermal performance throughout their lifespan.

References

1. Thermal Performance of Buildings. (2022). International Energy Agency.

2. Sandwich Panel Technology. (2021). Journal of Building Engineering, 35, 102007.

3. Energy Efficiency in Building Materials. (2023). U.S. Department of Energy.

4. Corrugated Panel Design and Applications. (2022). Architectural Engineering and Design Management, 18(3), 231-245.