- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Compare thermal performance of corrugated steel vs insulated panels

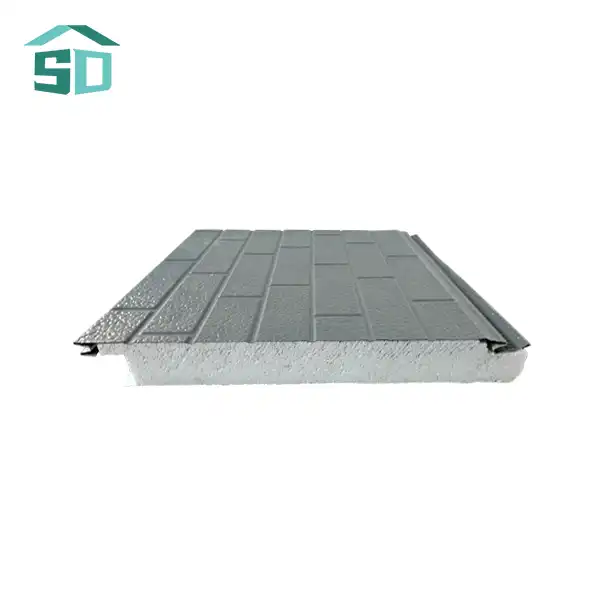

When it comes to building envelope solutions, the thermal performance of exterior cladding plays a crucial role in energy efficiency and occupant comfort. Corrugated steel siding panels and insulated panels are two popular options, each with distinct thermal characteristics. Corrugated steel siding panels offer durability and aesthetic appeal but generally provide lower thermal insulation on their own. In contrast, insulated panels, with their built-in insulation core, deliver superior thermal performance. The R-value of insulated panels can be up to 7 times higher than that of standalone corrugated steel, resulting in significantly better temperature control and energy savings. However, corrugated steel panels can be retrofitted with additional insulation to improve their thermal efficiency.

Understanding Thermal Performance in Building Materials

The Science Behind Heat Transfer

To comprehend the thermal performance of corrugated steel siding panels and insulated panels, it's essential to grasp the fundamentals of heat transfer. Heat moves through building materials via conduction, convection, and radiation. Conduction occurs when heat travels through a solid material, while convection involves heat transfer through air or liquid movement. Radiation is the transfer of heat through electromagnetic waves. The ability of a material to resist heat flow is measured by its R-value, with higher values indicating better insulation properties.

Factors Affecting Thermal Performance

Several factors influence the thermal performance of building materials, including thickness, density, and composition. For corrugated steel siding panels, the metal's high thermal conductivity can lead to rapid heat transfer. However, the corrugated design creates air pockets that can provide some insulation. Insulated panels, on the other hand, incorporate materials specifically designed for thermal resistance, such as polyurethane or polystyrene foam cores. These materials significantly reduce heat flow, resulting in superior thermal performance.

Measuring Thermal Efficiency

The thermal efficiency of building materials is typically measured using R-values and U-values. R-value represents thermal resistance, with higher numbers indicating better insulation. U-value measures heat transfer rate, with lower numbers signifying better insulation. When comparing corrugated steel siding panels to insulated panels, it's crucial to consider these metrics to make informed decisions about thermal performance in construction projects.

Corrugated Steel Siding Panels: Thermal Characteristics and Enhancements

Inherent Thermal Properties of Steel

Corrugated steel siding panels, known for their strength and durability, have unique thermal characteristics. Steel is an excellent conductor of heat, which can be both advantageous and challenging in terms of thermal performance. The high thermal conductivity of steel allows for quick heat dissipation, which can be beneficial in certain climates. However, this property also means that standalone corrugated steel panels may not provide significant insulation without additional measures.

Impact of Corrugation on Thermal Performance

The corrugated design of steel siding panels introduces an interesting dynamic to their thermal performance. The ridges and valleys created by corrugation form air pockets, which can act as a rudimentary form of insulation. These air spaces help to reduce heat transfer by creating a barrier between the exterior and interior environments. While not as effective as dedicated insulation materials, the corrugated structure does offer some improvement over flat steel panels in terms of thermal resistance.

Enhancing Thermal Efficiency of Corrugated Steel Panels

To improve the thermal performance of corrugated steel siding panels, various enhancement strategies can be employed. One common approach is to add a layer of insulation behind the panels. This can be achieved using materials such as fiberglass batts, foam board, or spray foam insulation. Another method is to apply reflective coatings to the panels, which can help reduce heat absorption from solar radiation. Some manufacturers also offer corrugated steel siding panels with integrated insulation, combining the strength of steel with improved thermal properties.

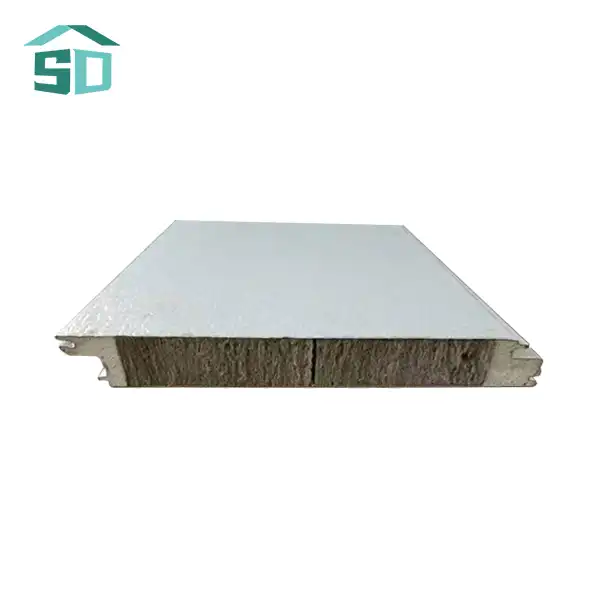

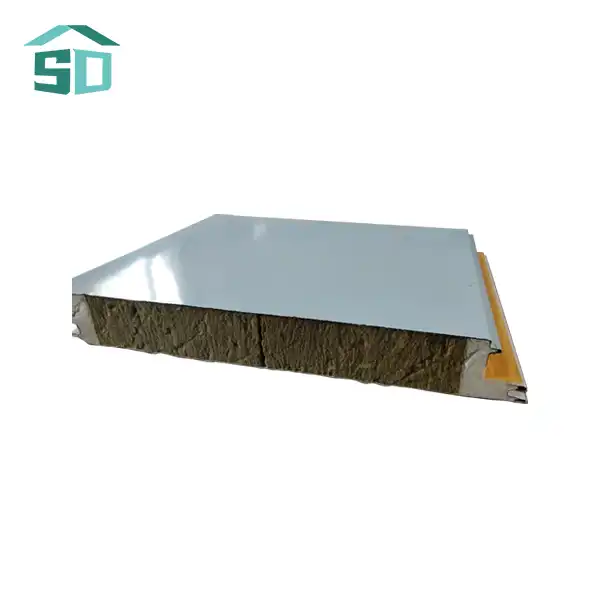

Insulated Panels: Advanced Thermal Solutions

Composition and Design of Insulated Panels

Insulated panels represent a more advanced thermal solution compared to traditional corrugated steel siding panels. These panels typically consist of two metal facings sandwiching a core of insulating material. The most common insulation materials used are polyurethane and polystyrene foam, known for their excellent thermal resistance properties. The design of insulated panels allows for seamless integration of insulation within the building envelope, providing a continuous thermal barrier.

Thermal Performance Advantages

The primary advantage of insulated panels lies in their superior thermal performance. The insulation core significantly reduces heat transfer, resulting in much higher R-values compared to standalone corrugated steel siding panels. This enhanced thermal efficiency translates to better temperature control inside buildings, reduced energy consumption for heating and cooling, and improved overall comfort for occupants. The continuous insulation provided by these panels also helps minimize thermal bridging, a common issue in traditional construction methods.

Customization and Versatility

Insulated panels offer a high degree of customization in terms of thermal performance. Manufacturers can adjust the thickness and type of insulation core to meet specific R-value requirements for different climate zones and building codes. This versatility allows architects and builders to optimize thermal performance while maintaining design flexibility. Additionally, insulated panels can be fabricated with various exterior finishes, including corrugated patterns, to achieve desired aesthetic effects while benefiting from advanced thermal properties.

Conclusion

In comparing the thermal performance of corrugated steel siding panels and insulated panels, it's clear that each option has its strengths. Corrugated steel panels offer durability and design flexibility but require additional measures to enhance thermal efficiency. Insulated panels, with their built-in thermal resistance, provide superior insulation and energy efficiency. The choice between these options depends on specific project requirements, climate considerations, and energy performance goals. Both solutions have their place in modern construction, offering architects and builders versatile tools for creating thermally efficient and aesthetically pleasing building envelopes.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of thermal performance in exterior cladding solutions. As a trusted corrugated steel siding panels factory, our range of corrugated steel siding panels and insulated panels is designed to meet diverse project needs while prioritizing energy efficiency and occupant comfort. Whether you're looking for the classic appeal of corrugated steel or the advanced thermal properties of insulated panels, we have the expertise to guide you towards the best solution for your project. Contact us at info@sdqsc.com to explore how our products can elevate your building's thermal performance and overall quality.

FAQs

Can corrugated steel siding panels be as thermally efficient as insulated panels?

While standalone corrugated steel panels typically have lower thermal efficiency, they can be enhanced with additional insulation to approach the performance of insulated panels.

Are insulated panels more expensive than corrugated steel siding panels?

Generally, insulated panels have a higher upfront cost, but they can lead to significant energy savings over time, potentially offsetting the initial investment.

How do weather conditions affect the choice between these panel types?

In extreme climates, insulated panels often provide better thermal protection, while corrugated steel panels may be sufficient in milder conditions.

References

1. American Iron and Steel Institute. (2021). "Steel and Thermal Performance in Buildings."

2. U.S. Department of Energy. (2022). "Insulation Materials for Buildings."

3. Building Science Corporation. (2020). "Thermal Performance of Building Envelopes."

4. Journal of Building Engineering. (2021). "Comparative Study of Thermal Performance in Metal Cladding Systems."

5. International Journal of Energy Research. (2022). "Advancements in Building Insulation Technologies."