Grasping Corrugated Sandwich Panels in Prefab Construction

Composition and Structure of Corrugated Sandwich Panels

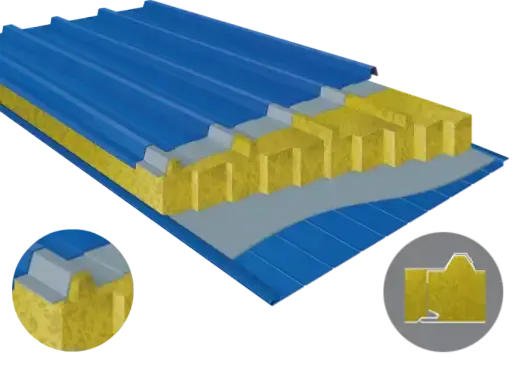

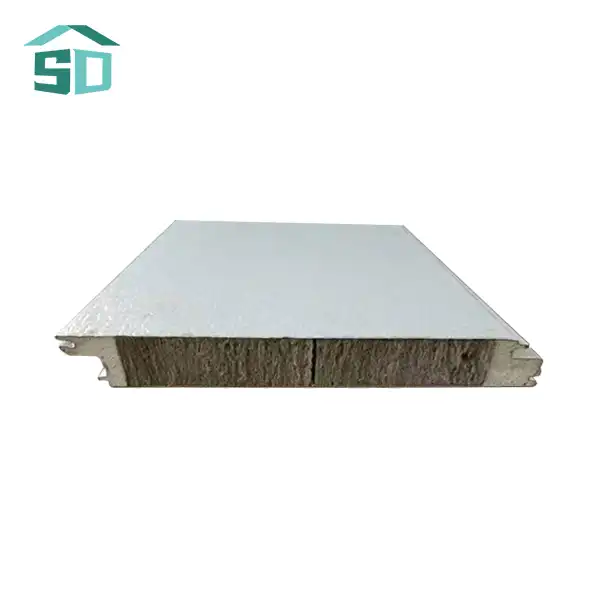

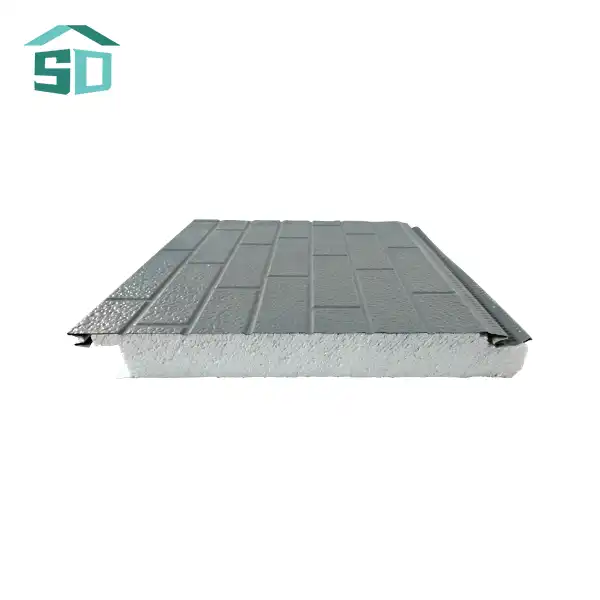

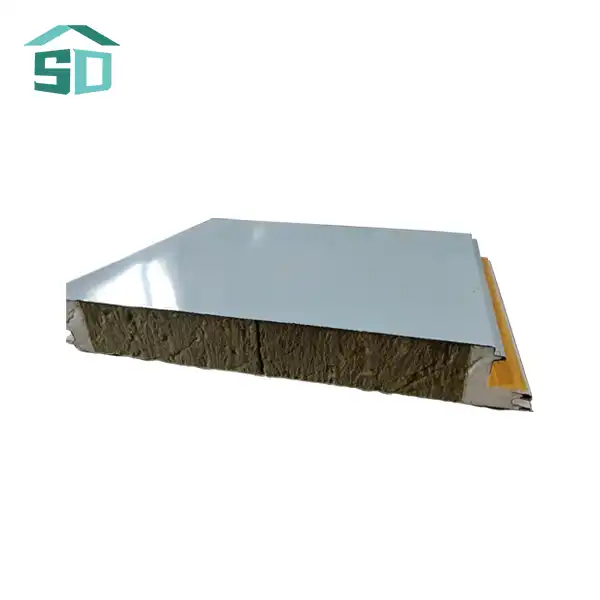

Corrugated sandwich panels are engineered building components that consist of three main layers. The outer layers, known as facings, are typically made of metal sheets, often steel or aluminum. These facings are profiled or corrugated to enhance their structural strength and provide a distinctive appearance. Between these metal skins lies the core material, usually a rigid insulation such as polyurethane foam, polyisocyanurate, or mineral wool.

The unique structure of corrugated sandwich panels offers several advantages. The corrugated design of the metal facings increases the panel's overall rigidity and load-bearing capacity. This allows the panels to span greater distances without additional support, reducing the need for secondary structural elements in prefab buildings. The insulating core not only provides thermal efficiency but also contributes to the panel's structural integrity through its bonding with the metal facings.

Benefits of Using Corrugated Sandwich Panels in Prefab Buildings

Corrugated sandwich panels offer numerous benefits that make them an excellent choice for prefab construction:

- Thermal Efficiency: The insulating core provides superior thermal performance, reducing heating and cooling costs.

- Lightweight yet Strong: Despite their light weight, these panels offer impressive structural strength, simplifying transportation and installation.

- Quick Installation: Prefabricated panels can be rapidly installed, significantly reducing on-site construction time.

- Versatility: Suitable for walls, roofs, and even flooring in some applications, offering design flexibility.

- Durability: Resistant to weather, corrosion, and fire, ensuring long-term performance.

- Cost-Effective: While initial costs may be higher than some alternatives, the long-term energy savings and reduced maintenance needs offer excellent value.

Applications of Corrugated Sandwich Panels in Various Prefab Structures

The versatility of corrugated sandwich panels makes them suitable for a wide range of prefab building applications:

- Industrial Buildings: Warehouses, factories, and storage facilities benefit from the panels' durability and insulation properties.

- Commercial Structures: Offices, retail spaces, and exhibition halls can utilize these panels for quick construction and energy efficiency.

- Agricultural Buildings: Barns, greenhouses, and storage sheds can be quickly erected using these panels, offering protection from the elements.

- Residential Prefab Homes: Modern prefab houses often incorporate these panels for their excellent insulation and aesthetic appeal.

- Cold Storage Facilities: The superior insulation properties make these panels ideal for maintaining controlled temperatures in cold storage units.

Comparing Corrugated Sandwich Panels with Other Prefab Panel Options

Structural Insulated Panels (SIPs) vs. Corrugated Sandwich Panels

Structural Insulated Panels (SIPs) are another popular option in prefab construction. Like corrugated sandwich panels, SIPs consist of an insulating foam core sandwiched between two structural facings. However, there are several key differences:

- Facing Material: SIPs typically use oriented strand board (OSB) or plywood facings, while corrugated sandwich panels use metal facings.

- Structural Performance: Corrugated sandwich panels often offer superior structural strength due to their metal facings and corrugated design.

- Versatility: Corrugated sandwich panels are more versatile, suitable for both walls and roofing, while SIPs are primarily used for walls and floors.

- Weather Resistance: The metal facings of corrugated sandwich panels provide better weather resistance compared to the wood-based facings of SIPs.

- Installation: Both options offer quick installation, but corrugated sandwich panels may have an edge in larger commercial or industrial applications.

Metal Composite Panels vs. Corrugated Sandwich Panels

Metal composite panels, such as aluminum composite panels (ACPs), are another alternative in prefab construction. Here's how they compare to corrugated sandwich panels:

- Composition: Metal composite panels consist of two thin metal sheets bonded to a non-metal core, often plastic. Corrugated sandwich panels have a thicker insulating core between metal facings.

- Insulation: Corrugated sandwich panels offer superior insulation due to their thicker insulating core.

- Structural Strength: The corrugated design and thicker construction of corrugated sandwich panels generally provide better structural performance.

- Aesthetics: Metal composite panels often offer a wider range of finishes and colors, making them popular for decorative façades.

- Fire Safety: Corrugated sandwich panels with appropriate core materials can offer better fire resistance compared to some metal composite panels.

Fiber Cement Boards vs. Corrugated Sandwich Panels

Fiber cement boards are another option in prefab construction, particularly for exterior cladding. Here's how they stack up against corrugated sandwich panels:

- Composition: Fiber cement boards are made from a mixture of cement, cellulose fibers, and sand. They lack the insulating core found in corrugated sandwich panels.

- Insulation: Corrugated sandwich panels provide significantly better insulation due to their built-in insulating core.

- Weight: Corrugated sandwich panels are generally lighter, making them easier to transport and install.

- Versatility: While fiber cement boards are primarily used for exterior cladding, corrugated sandwich panels can serve as both structural and insulating elements.

- Durability: Both options offer good durability, but corrugated sandwich panels may have an edge in severe weather conditions due to their metal facings.

Customization and Installation of Corrugated Sandwich Panels

Customization Options for Corrugated Sandwich Panels

One of the key advantages of corrugated sandwich panels is their high degree of customizability. Manufacturers like Weifang Sandong Building Materials Co., Ltd. offer various options to tailor these panels to specific project requirements:

- Panel Thickness: The overall thickness of the panel can be adjusted to meet specific insulation and structural requirements.

- Core Material: Different insulating materials can be used for the core, such as polyurethane, polyisocyanurate, or mineral wool, each offering unique properties.

- Facing Material: While steel is common, aluminum or other metals can be used for the facings, depending on the application.

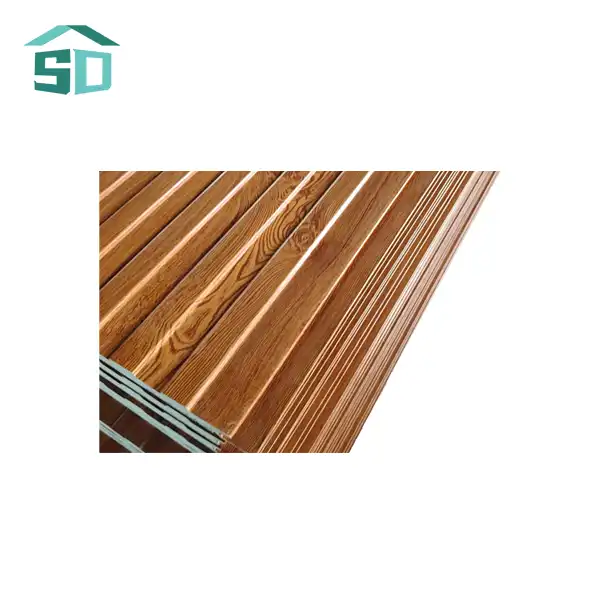

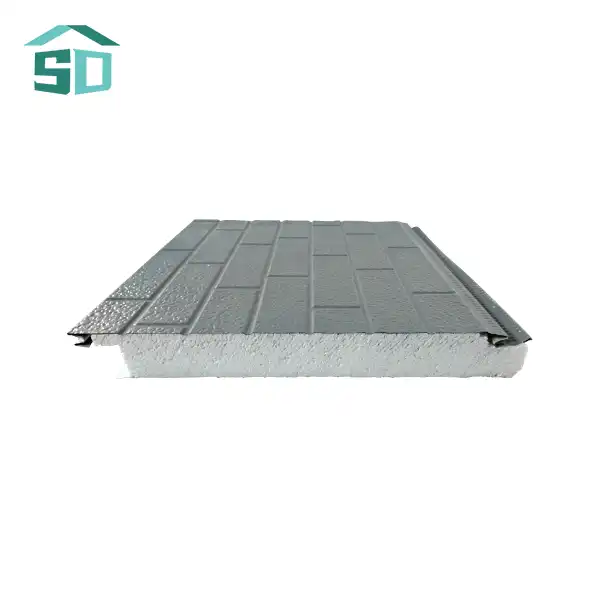

- Corrugation Profile: Various corrugation patterns are available, affecting both the panel's structural properties and aesthetic appearance.

- Color and Finish: A wide range of colors and finishes can be applied to the metal facings, allowing for design flexibility.

- Joint Systems: Different joint designs are available to suit various installation methods and weather-sealing requirements.

Customized corrugated sandwich panels can be tailored to meet specific project requirements, whether it's enhanced fire resistance for industrial applications, increased thermal performance for cold storage facilities, or unique aesthetic designs for commercial buildings.

Installation Process and Best Practices

The installation of corrugated sandwich panels is a critical process that significantly impacts the performance and longevity of the prefab structure. Here are some key steps and best practices:

Preparation:

- Ensure the supporting structure is level and properly aligned.

- Check that all necessary tools and equipment are on-site and in good condition.

- Review the installation plan and panel layout before beginning.

Panel Handling:

- Use appropriate lifting equipment to avoid damage to panels during unloading and positioning.

- Store panels in a dry, covered area to protect them from moisture and dirt.

Installation Sequence:

- Begin installation from one corner of the building, ensuring the first panel is perfectly square.

- Install panels in the sequence specified by the manufacturer, typically working from bottom to top for walls.

Joining Panels:

- Use the specified joint system, ensuring a tight fit between panels.

- Apply sealants or gaskets as required to ensure weather-tightness.

Fastening:

- Use the correct type and number of fasteners as specified by the manufacturer.

- Avoid over-tightening fasteners, which can damage the panel surface.

Cutting and Trimming:

- Use appropriate tools for cutting panels, such as circular saws with fine-toothed blades.

- Make clean, straight cuts to ensure proper fitting and sealing.

Weather Sealing:

- Pay special attention to joints, corners, and openings to ensure proper weather sealing.

- Use manufacturer-recommended sealants and flashing materials.

- Proper installation is crucial for maximizing the benefits of corrugated sandwich panels. It's often advisable to work with experienced installers or seek guidance from the panel manufacturer to ensure optimal results.

Maintenance and Long-term Performance of Corrugated Sandwich Panels

While corrugated sandwich panels are known for their durability and low maintenance requirements, proper care can further extend their lifespan and maintain their performance:

- Regular Inspections: Conduct visual inspections at least annually to check for any damage, loose fasteners, or signs of wear.

- Cleaning: Periodically clean the panel surfaces using mild detergent and water to remove dirt and prevent staining.

- Sealant Maintenance: Check and replace sealants as needed, particularly around joints and openings.

- Repair Damage Promptly: Address any scratches, dents, or other damage quickly to prevent moisture ingress or further deterioration.

- Paint Touch-ups: For painted panels, touch up any areas where the paint has chipped or worn to prevent corrosion.

- Gutter and Drainage Maintenance: Ensure proper functioning of gutters and drainage systems to prevent water accumulation on or around panels.

Conclusion

Corrugated sandwich panels emerge as a top choice for prefab building construction, offering a compelling combination of structural strength, thermal efficiency, and design flexibility. Their versatility makes them suitable for a wide range of applications, from industrial warehouses to modern residential homes. While alternatives like SIPs, metal composite panels, and fiber cement boards each have their merits, corrugated sandwich panels often provide the best overall value, particularly for larger-scale projects.

For those considering corrugated sandwich panels for their next prefab project, Weifang Sandong Building Materials Co., Ltd. offers high-quality, customizable options. Their commitment to manufacturing excellence and comprehensive quality control ensures that you receive panels that meet the highest standards of performance and durability. To explore how corrugated sandwich panels can benefit your specific project or to learn more about their range of exterior cladding and facade solutions, don't hesitate to reach out to their team of experts at info@sdqsc.com.

FAQ

What are the main advantages of using corrugated sandwich panels in prefab construction?

Corrugated sandwich panels offer excellent thermal insulation, structural strength, quick installation, versatility, durability, and cost-effectiveness over time.

How do corrugated sandwich panels compare to traditional building materials?

Compared to traditional materials, corrugated sandwich panels often provide better insulation, faster construction times, and lower long-term maintenance costs.

Can corrugated sandwich panels be used for both walls and roofing in prefab buildings?

Yes, these panels are versatile and can be used for walls, roofs, and even flooring in some applications, offering design flexibility.

What customization options are available for corrugated sandwich panels?

Customization options include panel thickness, core material, facing material, corrugation profile, color, finish, and joint systems.

How long can corrugated sandwich panels last with proper maintenance?

With proper installation and maintenance, corrugated sandwich panels can last for decades, often maintaining their structural and insulating properties throughout their lifespan.

References

1. Alam, M. A., & Sanjayan, J. (2018). Thermal performance and fire resistance of metal sandwich panels. Journal of Building Engineering, 18, 197-206.

2. Davies, J. M. (2001). Lightweight sandwich construction. John Wiley & Sons.

3. Hassanieh, A., Valipour, H. R., & Bradford, M. A. (2017). Experimental and analytical behaviour of sandwich panels utilizing semi-rigid foam core. Journal of Constructional Steel Research, 138, 23-34