Introducing the Superior Performance of PU Insulation Panels in Industrial Settings

PU insulation panels have revolutionized the way factories approach thermal management and energy efficiency. These innovative panels offer a unique combination of properties that make them ideally suited for industrial applications. At the heart of their performance is the exceptional thermal insulation capability, with a thermal conductivity of just 0.018 W/m.K. This low thermal conductivity translates to superior heat retention in winter and effective heat rejection in summer, leading to significant energy savings for factories.

The thermal resistance of PU insulation panels, measured at 2.09 m²K/W, further underscores their effectiveness in maintaining stable indoor temperatures. This high R-value ensures that factories can maintain optimal working conditions year-round while minimizing heating and cooling costs. The energy efficiency provided by these panels not only reduces operational expenses but also contributes to a smaller carbon footprint, aligning with the growing emphasis on sustainable industrial practices.

Durability and Longevity in Harsh Industrial Environments

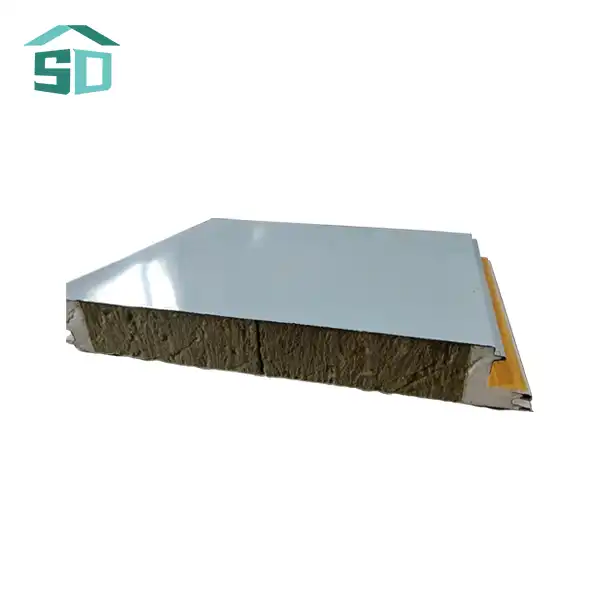

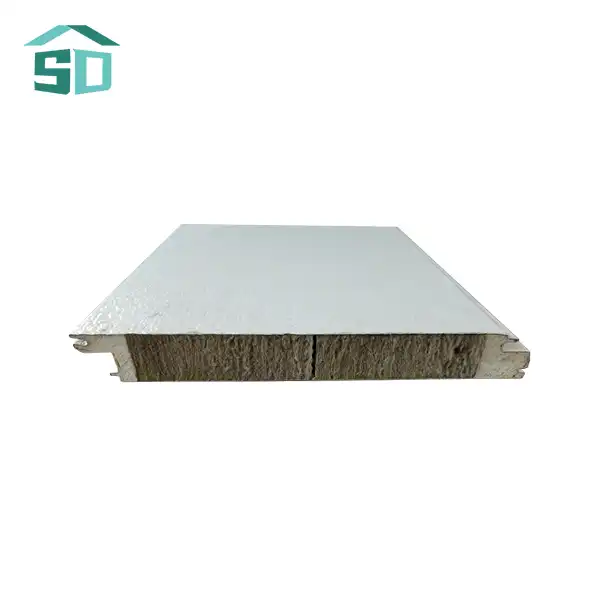

Industrial settings often present challenging conditions for building materials, but PU insulation panels rise to the occasion with their robust construction and resistance to various environmental factors. These panels demonstrate remarkable durability, withstanding the rigors of industrial operations without compromising their insulative properties. The corrosion-free nature of PU insulation panels makes them particularly suitable for factories that may be exposed to harsh chemicals or high humidity levels.

The longevity of PU insulation panels is further enhanced by their resistance to weathering and UV damage. With a wind resistance of 8.0 kPa, these panels can withstand severe weather conditions, ensuring the structural integrity of factory buildings even in areas prone to high winds or storms. This resilience translates to reduced maintenance costs and longer intervals between replacements, providing a cost-effective solution for factory owners looking to maximize their investment in insulation materials.

Fire Safety and Compliance: A Critical Aspect of Factory Insulation

In industrial settings, fire safety is paramount, and PU insulation panels address this concern with their impressive fire-resistant properties. The panels achieve a fire protection rating of B1/B2, meeting stringent safety standards and regulations. This high level of fire resistance is crucial in factories where the risk of fire may be elevated due to the nature of industrial processes or the presence of flammable materials.

The fire-resistant properties of PU insulation panels contribute significantly to overall building safety, potentially slowing the spread of fire and providing valuable time for evacuation in the event of an emergency. This enhanced safety profile not only protects human life and valuable assets but also helps factories comply with increasingly strict building codes and insurance requirements. By choosing PU insulation panels with advanced fire-resistant properties, factory owners demonstrate a commitment to safety that extends beyond mere regulatory compliance.

Innovative Design Features for Enhanced Performance

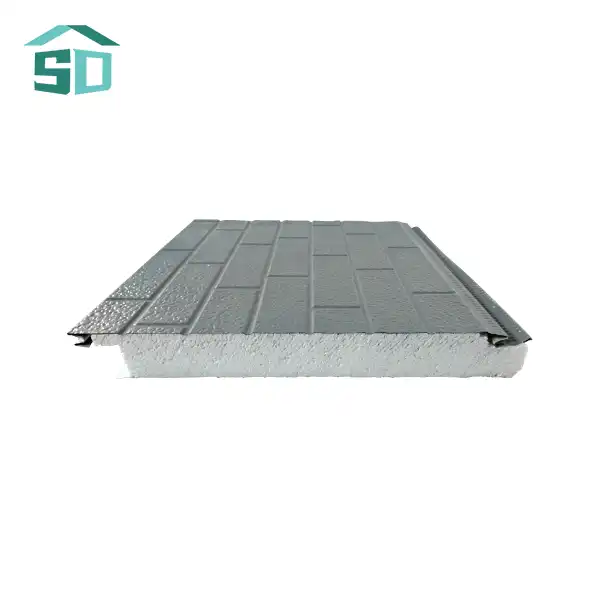

The effectiveness of PU insulation panels in industrial settings is further augmented by their innovative design features. These panels are available in a range of thicknesses, typically 16mm or 20mm for exterior applications and 10mm for interior use. This versatility allows for tailored insulation solutions that meet the specific needs of different areas within a factory.

The surface materials of PU insulation panels, available in thicknesses of 0.23mm, 0.25mm, and 0.27mm, provide an additional layer of protection and contribute to the overall durability of the panels. This outer layer not only enhances the panels' resistance to physical damage but also plays a role in their aesthetic appeal, allowing factories to maintain a professional and well-maintained appearance.

Customization and Versatility: Meeting Diverse Industrial Needs

One of the key advantages of PU insulation panels is their adaptability to various industrial applications. These panels can be customized in terms of length, width, and thickness to fit the specific requirements of different factory layouts and building designs. The standard width for exterior panels is 383mm, while interior panels typically measure 450mm in width. However, these dimensions can be adjusted to accommodate unique architectural features or structural constraints.

The versatility of PU insulation panels extends beyond their physical dimensions. These panels can be manufactured in a wide range of colors and finishes, allowing factories to maintain a cohesive aesthetic that aligns with their brand identity or specific design preferences. This customization potential makes PU insulation panels suitable for both new construction projects and renovations of existing industrial facilities.

Environmental Considerations and Sustainable Manufacturing

As industries increasingly prioritize sustainability, the eco-friendly aspects of PU insulation panels have become a significant selling point. These panels are manufactured using environmentally conscious processes and materials, contributing to green building initiatives and helping factories reduce their overall environmental impact. The energy efficiency provided by PU insulation panels also plays a crucial role in reducing a factory's carbon footprint over the long term.

Moreover, the durability and longevity of PU insulation panels mean fewer replacements over time, reducing waste and the need for frequent manufacturing of new materials. This aspect of sustainability extends throughout the lifecycle of the panels, from production to installation and eventual disposal or recycling. By choosing PU insulation panels, factory owners invest in a solution that not only meets their immediate insulation needs but also aligns with broader environmental goals and corporate sustainability initiatives.

Conclusion

As we look towards 2025, it's clear that PU insulation panels will continue to be the preferred choice for factory insulation among professionals. Their unmatched combination of thermal efficiency, durability, fire resistance, and customization options positions them as a superior solution for industrial applications. By investing in high-quality PU insulation panels, factory owners can ensure optimal energy efficiency, enhanced safety, and long-term cost savings while also contributing to more sustainable industrial practices.

For more information on how PU insulation panels can benefit your factory or to explore our range of exterior cladding and facade solutions, please don't hesitate to contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is ready to assist you in finding the perfect insulation solution for your industrial needs.