The Rise of Prefabricated Thermal Panels in Modern Construction

Prefabricated thermal panels have gained significant traction in recent years, and for good reason. These engineered panels offer a unique combination of thermal efficiency, durability, and ease of installation that traditional insulation methods struggle to match.

What Are Prefabricated Thermal Panels?

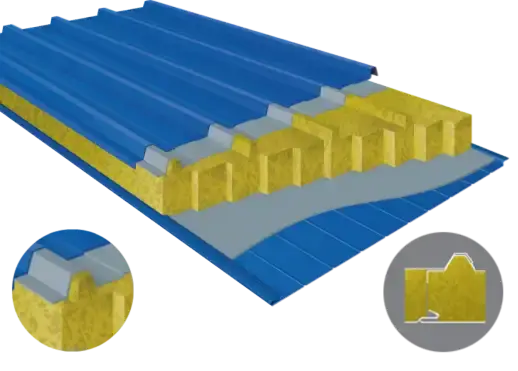

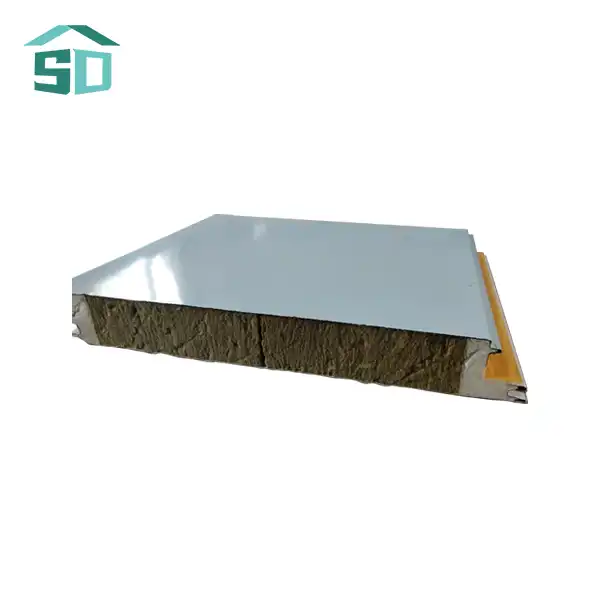

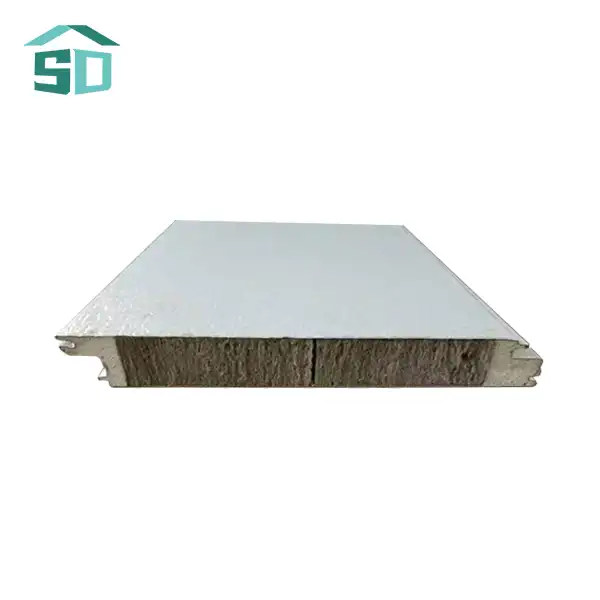

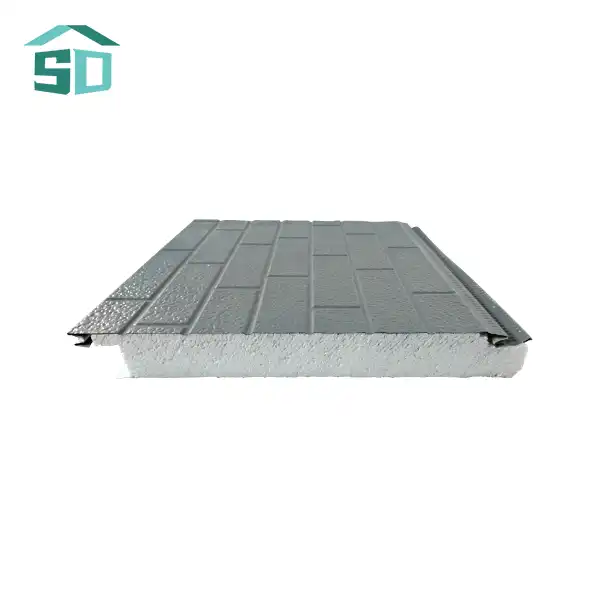

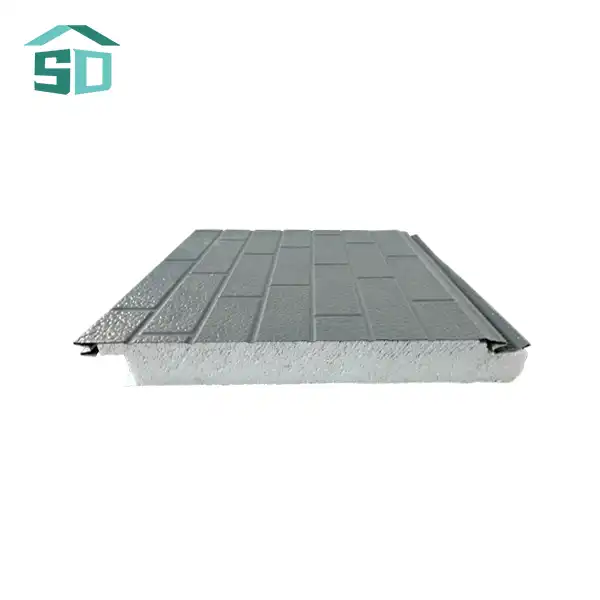

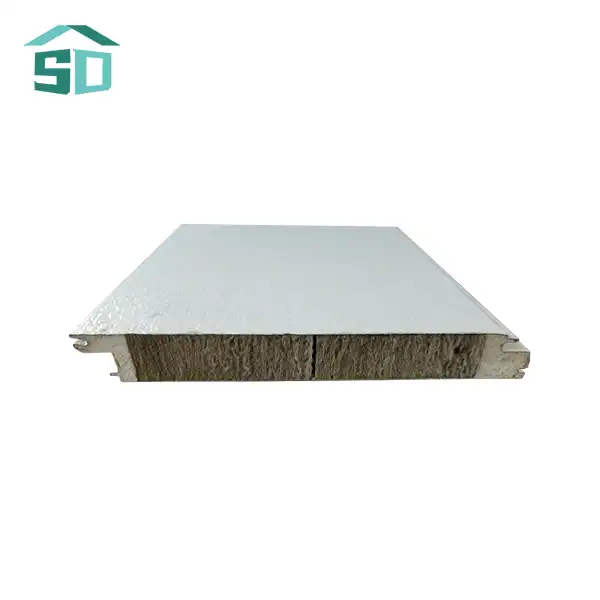

Prefabricated thermal panels are factory-made insulation units designed for quick and efficient installation in various building types. These panels typically consist of a high-performance insulation core sandwiched between two layers of structural material, such as steel or aluminum. The result is a robust, energy-efficient panel that can be customized to meet specific project requirements.

The insulation core provides excellent thermal resistance, reducing heat transfer and improving overall building efficiency, while the outer layers ensure exceptional strength and protection against environmental factors. With customizable thicknesses, finishes, and colors, these panels can be adapted for a wide range of architectural applications, from commercial buildings to residential projects.

Key Benefits for B2B Buyers

B2B buyers are increasingly turning to prefabricated thermal panels for several compelling reasons:

- Superior Thermal Performance: These panels offer exceptional insulation properties, significantly reducing heat transfer and improving overall energy efficiency.

- Time and Cost Savings: The prefabricated nature of these panels allows for rapid installation, reducing on-site labor costs and project timelines.

- Versatility: Prefabricated thermal panels can be used in a wide range of applications, from exterior walls to roofing systems.

- Durability: Engineered to withstand harsh environmental conditions, these panels offer long-lasting performance and reduced maintenance needs.

- Aesthetic Flexibility: Many prefabricated thermal panel manufacturers offer customizable finishes and colors to meet diverse architectural requirements.

The Economic Impact of Choosing Prefabricated Thermal Panels

When considering the worth of prefabricated thermal panels, B2B buyers must look beyond the initial investment and consider the long-term economic benefits.

Energy Cost Reduction

One of the most significant advantages of prefabricated thermal panels is their ability to dramatically reduce energy costs. By providing superior insulation, these panels minimize heat loss in winter and heat gain in summer, leading to lower heating and cooling expenses throughout the year. This energy efficiency not only benefits the environment but also results in measurable cost savings for building owners. For large commercial or industrial facilities, the reduction in energy consumption can translate into thousands of dollars in savings over the building’s lifespan.

Installation Efficiency and Labor Savings

Prefabricated thermal panels are designed for quick and straightforward installation, making them highly suitable for projects with tight deadlines. Their modular construction allows for seamless assembly, reducing the need for specialized labor and minimizing on-site adjustments. This efficiency not only cuts down labor costs but also shortens construction timelines, allowing faster project delivery. For businesses, this means less downtime and minimal disruption to daily operations during installation or renovation processes.

Long-Term Durability and Maintenance Savings

Investing in high-quality prefabricated thermal panels from a reputable prefabricated thermal panels manufacturer can deliver outstanding long-term economic and performance benefits. These panels are specifically designed to endure harsh weather conditions, temperature fluctuations, and prolonged exposure to moisture and UV radiation without losing their structural integrity. Their advanced construction materials and protective coatings minimize the risk of corrosion, warping, or surface degradation. As a result, building owners experience reduced maintenance requirements, lower operational costs, and improved energy efficiency throughout the building’s lifespan. Over time, the initial investment proves to be highly cost-effective and sustainable.

Sustainability and Environmental Considerations

In today's eco-conscious business environment, the sustainability aspects of building materials are increasingly important to B2B buyers.

Energy Efficiency and Carbon Footprint Reduction

Prefabricated thermal panels play a crucial role in reducing a building's carbon footprint. By significantly improving energy efficiency, these panels help decrease the overall energy consumption of a structure. This reduction in energy use translates directly into lower greenhouse gas emissions, aligning with corporate sustainability goals and environmental regulations.

Recyclability and Eco-Friendly Materials

Many prefabricated thermal panel manufacturers are now focusing on using recyclable and eco-friendly materials in their products. Some panels are made with recycled content, while others are designed to be easily recyclable at the end of their life cycle. This focus on sustainability adds another layer of value for environmentally conscious B2B buyers.

Contribution to Green Building Certifications

The use of prefabricated thermal panels can contribute significantly to achieving green building certifications such as LEED (Leadership in Energy and Environmental Design). These certifications not only validate a company's commitment to sustainability but can also lead to various benefits, including tax incentives and improved marketability of the property.

Conclusion

Prefabricated thermal panels have proven their worth in the B2B market, offering a compelling combination of energy efficiency, cost-effectiveness, and sustainability. Their ability to reduce energy costs, streamline installation processes, and contribute to long-term building performance makes them an attractive option for a wide range of construction projects. As the construction industry continues to evolve towards more sustainable and efficient practices, prefabricated thermal panels are poised to play an increasingly important role in shaping the buildings of the future.

Are you ready to experience the benefits of prefabricated thermal panels for your next project? At Weifang Sandong Building Materials Co., Ltd., we offer a wide range of high-quality prefabricated thermal panels designed to meet your specific needs. From customizable colors and patterns to robust, long-lasting materials, our panels are engineered for optimal performance and aesthetic appeal. Contact us today at info@sdqsc.com to learn how our prefabricated thermal panels can transform your construction project and drive long-term value for your business.

Frequently Asked Questions

What are the typical applications for prefabricated thermal panels?

Prefabricated thermal panels are versatile and can be used in various applications, including exterior walls, roofs, and interior partitions for residential, commercial, and industrial buildings.

How do prefabricated thermal panels compare to traditional insulation methods?

Prefabricated thermal panels often offer superior insulation performance, faster installation, and better overall energy efficiency compared to traditional methods like fiberglass or spray foam insulation.

Are prefabricated thermal panels fire-resistant?

Many prefabricated thermal panels are designed with fire-resistant properties and can achieve high fire ratings, making them suitable for a wide range of building types and safety requirements.

References

1. U.S. Department of Energy. (2021). "Insulation Materials." Energy.gov.

2. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2017). "ASHRAE Handbook - Fundamentals." ASHRAE.

3. U.S. Green Building Council. (2022). "LEED Rating System." USGBC.org.

4. International Code Council. (2021). "International Energy Conservation Code." ICC Digital Codes.