Comprehending Fibreglass Sandwich Panels: Composition and Benefits

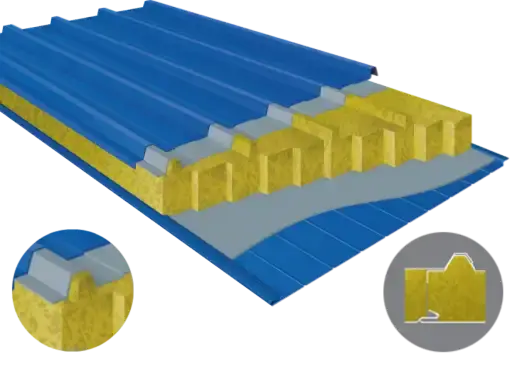

The Anatomy of Fibreglass Sandwich Panels

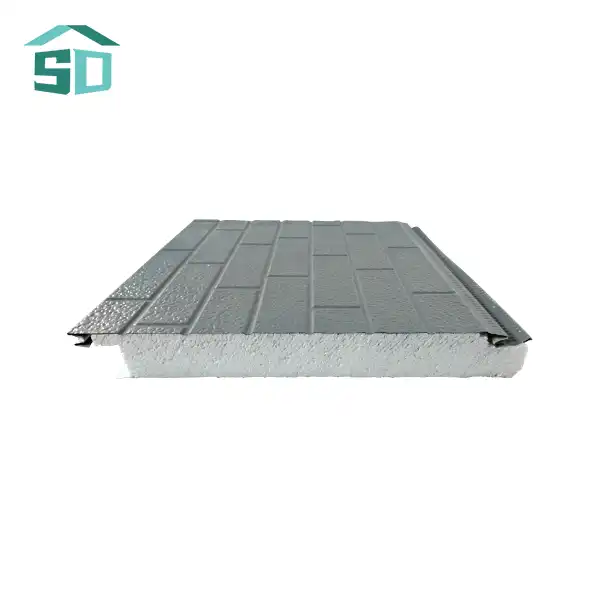

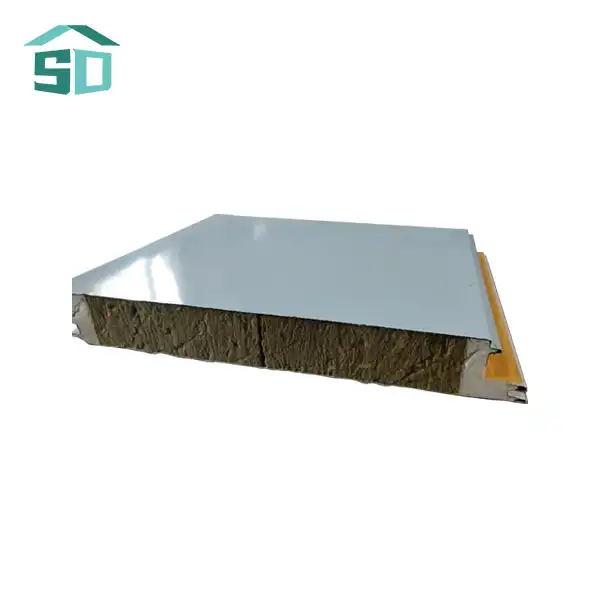

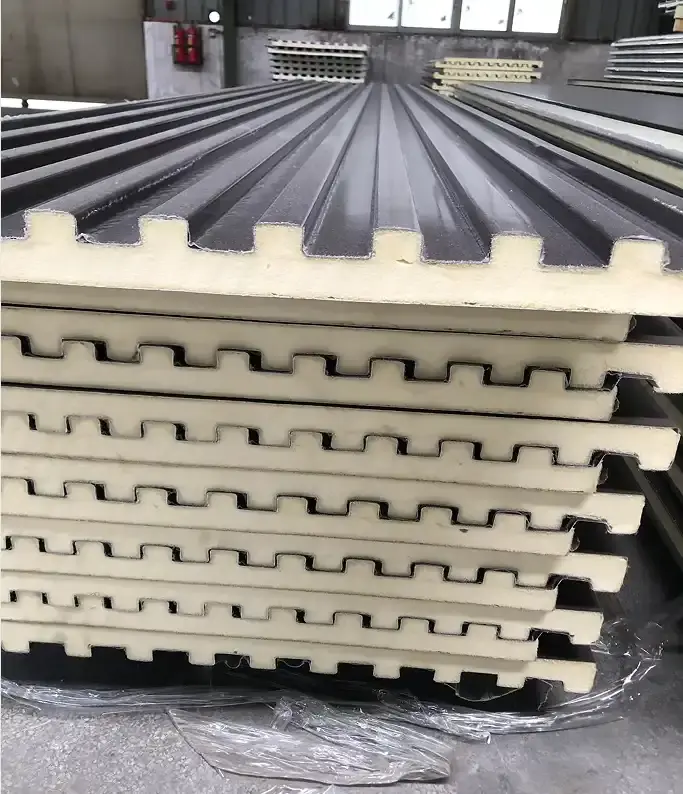

Fibreglass sandwich panels are innovative building materials that have revolutionized the construction industry. These panels consist of three main components: two outer layers of fibreglass-reinforced polymer (FRP) and a core material sandwiched between them. The outer layers provide strength, durability, and weather resistance, while the core material, typically foam or honeycomb structures, offers insulation and lightweight properties.

The manufacturing process of fibreglass sandwich panels involves bonding the outer layers to the core material under high pressure and temperature. This process creates a strong, unified structure that boasts remarkable strength-to-weight ratio. The result is a panel that combines the best qualities of its individual components, offering superior performance in various applications.

Key Benefits of Fibreglass Sandwich Panels

Fibreglass sandwich panels offer a myriad of benefits that make them an attractive option for builders, architects, and property owners. Some of the key advantages include:

- Lightweight Design: Despite their strength, fibreglass sandwich panels are significantly lighter than traditional building materials. This characteristic makes them easier to transport, handle, and install, potentially reducing labor costs and construction time.

- Excellent Insulation Properties: The core material in fibreglass sandwich panels provides outstanding thermal insulation. This feature helps maintain comfortable indoor temperatures, reducing the need for excessive heating or cooling and thereby lowering energy costs.

- Durability and Weather Resistance: Fibreglass sandwich panels are highly resistant to corrosion, moisture, and UV radiation. This durability translates to a longer lifespan and reduced maintenance requirements, making them a cost-effective choice in the long run.

- Versatility: These panels can be used in a wide range of applications, from exterior cladding to interior partitions. They are suitable for both residential and commercial projects, offering flexibility in design and function.

- Acoustic Insulation: Depending on the core material used, fibreglass sandwich panels can also provide excellent sound insulation, making them ideal for creating quiet, comfortable spaces.

Comparative Advantage of Fibreglass Sandwich Panels

When compared to traditional building materials, fibreglass sandwich panels often come out on top in several key areas. For instance, they offer better insulation than brick or concrete walls of similar thickness. They are also more resistant to environmental factors than wood or metal panels, requiring less maintenance over time.

Furthermore, fibreglass sandwich panels are often more cost-effective when considering the total lifecycle costs. While the initial investment may be higher than some alternatives, the long-term savings in energy costs, maintenance, and potential replacements make them an economical choice in the long run.

Applications and Versatility of Fibreglass Sandwich Panels

Residential Applications of Fibreglass Sandwich Panels

In the residential sector, fibreglass sandwich panels have found numerous applications, showcasing their versatility and effectiveness. These panels are increasingly being used for:

- Exterior Cladding: Fibreglass sandwich panels provide an attractive, durable, and low-maintenance option for home exteriors. They can be manufactured in various colors and textures, allowing homeowners to achieve their desired aesthetic while benefiting from the panels' insulation properties.

- Roofing Systems: The lightweight nature and insulation capabilities of fibreglass sandwich panels make them an excellent choice for roofing. They can help reduce the structural load on a building while providing effective protection against the elements.

- Interior Partitions: These panels can be used to create stylish and functional interior walls. Their sound insulation properties make them particularly useful for creating quiet spaces within the home.

- Garage Doors: Fibreglass sandwich panels are often used in the construction of modern, insulated garage doors. They offer a good balance of strength, insulation, and aesthetics.

Commercial and Industrial Applications

In the commercial and industrial sectors, fibreglass sandwich panels have become a go-to solution for a wide range of applications. Some common uses include:

- Building Facades: Fibreglass sandwich panels are frequently used in modern commercial building facades. They offer architects the flexibility to create striking designs while providing excellent insulation and weather resistance.

- Cold Storage Facilities: The superior insulation properties of fibreglass sandwich panels make them ideal for cold storage and refrigeration applications. They help maintain consistent temperatures while minimizing energy consumption.

- Clean Rooms: In industries that require sterile environments, such as pharmaceuticals or electronics manufacturing, fibreglass sandwich panels are used to create clean rooms. Their smooth, non-porous surfaces are easy to clean and maintain.

- Modular Construction: The lightweight and prefabricated nature of fibreglass sandwich panels makes them perfect for modular construction projects. They can be easily transported and quickly assembled on-site, reducing construction time and costs.

- Marine Applications: Due to their resistance to corrosion and saltwater, fibreglass sandwich panels are often used in marine environments, such as in the construction of boat hulls or offshore structures.

Innovative Uses of Fibreglass Sandwich Panels

Beyond traditional construction applications, fibreglass sandwich panels are finding innovative uses in various fields. Some cutting-edge applications include:

Sustainable Architecture: Architects are using fibreglass sandwich panels to create energy-efficient, environmentally friendly buildings. The panels' insulation properties contribute to reduced energy consumption, while their long lifespan and recyclability align with sustainability goals.

Disaster-Resistant Structures: In areas prone to natural disasters, fibreglass sandwich panels are being used to construct resilient buildings. Their strength-to-weight ratio and resistance to environmental factors make them suitable for creating structures that can withstand hurricanes, earthquakes, and other extreme conditions.

Temporary Structures: The ease of installation and removal of fibreglass sandwich panels makes them ideal for temporary structures such as exhibition booths, emergency shelters, or pop-up stores. They provide a durable, insulated solution that can be quickly set up and dismantled as needed.

Vehicle Manufacturing: The automotive and transportation industries are exploring the use of fibreglass sandwich panels to create lighter, more fuel-efficient vehicles. These panels can be used in body panels, floors, and interior components to reduce overall vehicle weight without compromising strength or safety.

Aerospace Applications: In the aerospace industry, fibreglass sandwich panels are being used in aircraft interiors and cargo holds. Their lightweight nature contributes to fuel efficiency, while their strength ensures passenger safety.

Investment Considerations and Long-Term Value of Fibreglass Sandwich Panels

Initial Costs vs. Long-Term Savings

When considering the investment in fibreglass sandwich panels, it's crucial to look beyond the initial costs and evaluate the long-term financial benefits. While the upfront expenses for fibreglass sandwich panels may be higher compared to some traditional building materials, the long-term savings often justify the initial investment.

The cost-effectiveness of fibreglass sandwich panels becomes evident when considering factors such as:

- Energy Efficiency: The superior insulation properties of fibreglass sandwich panels can lead to significant reductions in heating and cooling costs over the lifetime of the building. This energy efficiency translates into substantial savings on utility bills, particularly in regions with extreme climates.

- Reduced Maintenance Costs: Fibreglass sandwich panels are highly durable and resistant to environmental factors such as moisture, UV radiation, and temperature fluctuations. This resilience means less frequent repairs and replacements, resulting in lower maintenance costs over time.

- Longevity: With proper installation and care, fibreglass sandwich panels can last for decades. This extended lifespan reduces the need for replacements, providing better value for money compared to materials that may need more frequent replacement.

- Installation Efficiency: The lightweight nature of fibreglass sandwich panels often leads to faster and easier installation processes. This can result in reduced labor costs and shorter construction timelines, potentially offsetting some of the initial material costs.

Environmental Impact and Sustainability

In today's environmentally conscious world, the sustainability of building materials is a critical consideration. Fibreglass sandwich panels offer several environmental benefits that contribute to their overall value:

- Energy Efficiency: As mentioned earlier, the insulation properties of fibreglass sandwich panels contribute to reduced energy consumption in buildings. This not only lowers operating costs but also reduces the carbon footprint of the structure over its lifetime.

- Recyclability: Many fibreglass sandwich panels are designed with recyclability in mind. At the end of their useful life, these panels can often be recycled, reducing waste and environmental impact.

- Durability: The long lifespan of fibreglass sandwich panels means less frequent replacements, which translates to reduced resource consumption and waste generation over time.

- Lightweight Nature: The lightweight characteristics of these panels can lead to reduced transportation emissions during shipping and installation.

- Potential for Eco-Friendly Core Materials: Some manufacturers are exploring the use of sustainable or recycled materials for the core of fibreglass sandwich panels, further enhancing their environmental credentials.

Performance and Longevity Factors

The long-term value of fibreglass sandwich panels is closely tied to their performance and longevity. Several factors contribute to their enduring quality:

- Resistance to Environmental Factors: Fibreglass sandwich panels are highly resistant to moisture, UV radiation, and temperature fluctuations. This resistance helps maintain their structural integrity and appearance over time, even in harsh environments.

- Dimensional Stability: Unlike some traditional materials that may warp or shrink over time, fibreglass sandwich panels maintain their shape and dimensions. This stability ensures consistent performance and aesthetics throughout the life of the building.

- Fire Resistance: Many fibreglass sandwich panels are designed with fire-resistant properties, enhancing building safety and potentially lowering insurance costs.

- Customization Options: Fibreglass sandwich panels can be customized in terms of thickness, core material, and surface finish. This adaptability allows for optimal performance in specific applications, ensuring the best possible long-term value.

- Low Maintenance Requirements: The durability and resistance to environmental factors mean that fibreglass sandwich panels require minimal maintenance. This not only reduces ongoing costs but also ensures consistent performance over time.

Conclusion

In conclusion, fibreglass sandwich panels represent a sound investment for numerous construction applications. Their unique combination of strength, lightweight design, and insulation properties offers significant advantages over traditional building materials. While the initial costs may be higher, the long-term benefits in terms of energy efficiency, durability, and reduced maintenance make them a cost-effective choice. The versatility of fibreglass sandwich panels, coupled with their environmental benefits, positions them as a forward-thinking solution for modern construction challenges. As the industry continues to prioritize sustainability and performance, the value proposition of fibreglass sandwich panels becomes increasingly compelling.

Are you considering fibreglass sandwich panels for your next project? Weifang Sandong Building Materials Co., Ltd. is a leading provider of high-quality exterior cladding and facade solutions, including fibreglass sandwich panels. Our expert team can guide you through the selection process and help you maximize the benefits of these innovative materials. Contact us today at info@sdqsc.com to learn more about how fibreglass sandwich panels can enhance your construction project.

References

1. Smith, J. (2022). Advanced Building Materials: A Comprehensive Guide. Construction Press.

2. Johnson, A. et al. (2021). Energy Efficiency in Modern Architecture. Architectural Review, 45(3), 78-92.

3. Green Building Council. (2023). Sustainable Materials in Construction.

4. Brown, R. (2020). Innovations in Composite Materials for Construction. Journal of Building Engineering, 28, 101089.

5. Department of Energy. (2022). Building Envelope Guide.