The Composition and Waterproofing Capabilities of Steel PU Sandwich Panels

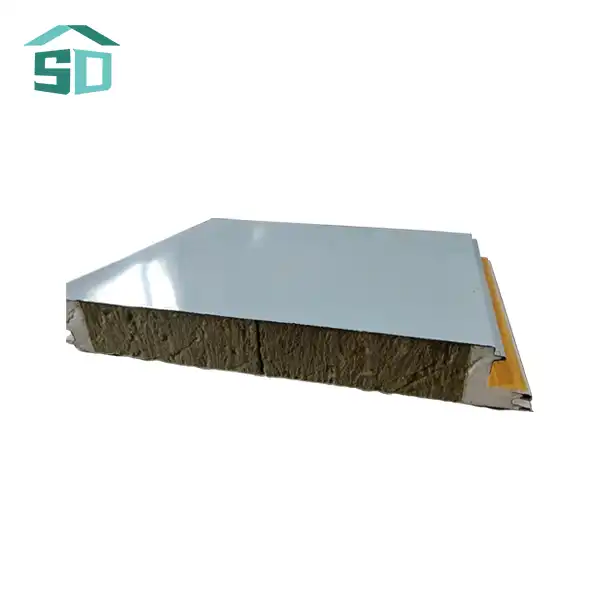

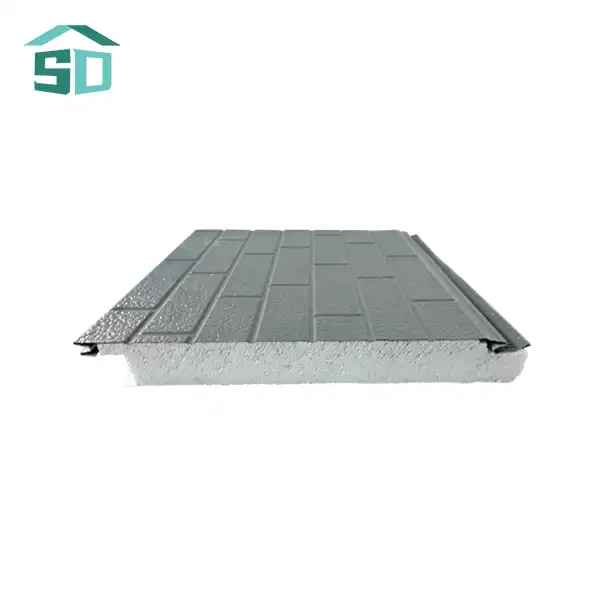

Steel PU sandwich panels are engineered to provide superior protection against the elements, particularly water. Their composition plays a pivotal role in their waterproofing capabilities. The panels consist of three main components: two steel facings and a polyurethane foam core.

The steel facings are typically galvanized or coated with protective materials such as polyester paint. This treatment not only enhances the panel's aesthetic appeal but also significantly improves its resistance to corrosion and water penetration. The steel layers act as the first line of defense against moisture, effectively repelling water and preventing it from reaching the interior of the structure.

The polyurethane foam core, sandwiched between the steel facings, is a key element in the panel's waterproofing abilities. Polyurethane foam is known for its closed-cell structure, which inherently resists water absorption. This property makes it an excellent insulator and contributes to the panel's overall water resistance.

Advanced Manufacturing Techniques

The manufacturing process of steel PU sandwich panels involves advanced techniques that further enhance their waterproofing capabilities. During production, the polyurethane foam is injected between the steel facings under high pressure. This process ensures a tight bond between the layers and eliminates any potential voids or gaps where water could penetrate.

Moreover, the edges of the panels are typically designed with interlocking systems or tongue-and-groove joints. These features create a tight seal when panels are connected, minimizing the risk of water ingress at the seams. Some manufacturers also apply additional sealants or gaskets at these joints during installation for extra protection.

Testing and Quality Control

Reputable manufacturers subject their steel PU sandwich panels to rigorous testing to ensure their waterproofing capabilities. These tests often include water spray tests, which simulate heavy rainfall conditions, and immersion tests to verify the panel's resistance to water absorption. Quality control measures are implemented throughout the production process to maintain consistent waterproofing performance across all panels.

Factors Affecting the Waterproofing Performance of Steel PU Sandwich Panels

While steel PU sandwich panels are inherently waterproof, several factors can influence their long-term performance in resisting water infiltration. Understanding these factors is crucial for maintaining the panels' effectiveness over time.

Installation Quality

The installation process plays a critical role in ensuring the waterproofing integrity of steel PU sandwich panels. Proper alignment and secure fastening of the panels are essential to prevent gaps or misalignments that could allow water penetration. Skilled installers use specialized techniques and tools to ensure a tight fit between panels and apply appropriate sealants at joints and connection points.

Furthermore, the use of compatible flashing and trim pieces around openings, corners, and roof-to-wall transitions is vital. These components help direct water away from vulnerable areas and maintain the overall water-tightness of the building envelope.

Environmental Conditions

The environment in which steel PU sandwich panels are installed can impact their waterproofing performance over time. Extreme weather conditions, such as heavy rainfall, high winds, or prolonged exposure to UV radiation, can gradually degrade the protective coatings on the steel facings or affect the integrity of sealants used at joints.

In coastal areas, salt spray can accelerate corrosion if the panels are not properly maintained. Similarly, in industrial environments, exposure to chemical pollutants may impact the longevity of the panel's waterproofing properties. Regular inspections and maintenance are crucial in these challenging environments to ensure ongoing water resistance.

Maintenance and Upkeep

Proper maintenance is essential for preserving the waterproofing capabilities of steel PU sandwich panels. Regular inspections should be conducted to check for any signs of damage, such as dents, scratches, or loosened fasteners, which could compromise the panel's water resistance.

Cleaning the panels periodically helps remove dirt, debris, and potential contaminants that could degrade the protective coatings over time. In some cases, reapplication of protective sealants or coatings may be necessary to maintain optimal waterproofing performance, especially in harsh environments or after many years of service.

Applications and Benefits of Waterproof Steel PU Sandwich Panels

The waterproof nature of steel PU sandwich panels makes them versatile and highly beneficial in various construction applications. Their ability to resist moisture infiltration, combined with other advantageous properties, has led to their widespread use in different sectors.

Industrial and Commercial Buildings

Steel PU sandwich panels are extensively used in industrial and commercial construction due to their excellent waterproofing capabilities. They are particularly valuable in facilities that require strict moisture control, such as food processing plants, pharmaceutical manufacturing units, and cold storage warehouses. The panels' ability to maintain a dry interior environment helps protect sensitive equipment, products, and materials from moisture damage.

In large-scale commercial buildings like shopping centers, office complexes, and sports arenas, these panels provide a durable and water-resistant building envelope. This not only protects the structure from water damage but also contributes to energy efficiency by preventing moisture-related heat loss or gain.

Residential Construction

In the residential sector, steel PU sandwich panels are gaining popularity for their waterproofing properties and aesthetic versatility. They are often used in modern home designs, particularly for roofing and exterior wall cladding. The panels' water resistance helps protect homes from leaks and water damage, while their insulation properties contribute to better energy efficiency and indoor comfort.

For areas prone to severe weather conditions, such as hurricanes or heavy rainfall, these panels offer an added layer of protection against water infiltration, helping to maintain the structural integrity of homes during extreme weather events.

Agricultural Buildings

The agricultural sector benefits significantly from the use of waterproof steel PU sandwich panels. In structures like barns, storage sheds, and livestock housing, these panels provide excellent protection against moisture, which is crucial for preserving harvested crops and maintaining animal health. The panels' resistance to water and ease of cleaning also make them ideal for maintaining hygienic conditions in agricultural facilities.

Additional Benefits

Beyond their primary waterproofing function, steel PU sandwich panels offer several other advantages that contribute to their popularity:

- Thermal Insulation: The polyurethane core provides excellent thermal insulation, reducing heating and cooling costs.

- Fire Resistance: Many steel PU sandwich panels are manufactured with fire-resistant properties, enhancing building safety.

- Lightweight Construction: Despite their durability, these panels are relatively lightweight, reducing structural load and simplifying installation.

- Customization Options: Panels can be manufactured in various colors and finishes to meet specific architectural requirements.

- Longevity: With proper installation and maintenance, steel PU sandwich panels can provide effective waterproofing and performance for many years, offering a long-term solution for building envelopes.

Conclusion

Steel PU sandwich panels have proven to be highly effective waterproof solutions for various construction applications. Their unique composition of steel facings and polyurethane foam core, combined with advanced manufacturing techniques, provides excellent resistance to water infiltration. Proper installation, regular maintenance, and consideration of environmental factors are crucial for maximizing their waterproofing performance. These panels offer numerous benefits beyond water resistance, including thermal insulation, fire resistance, and design flexibility, making them a versatile choice for modern construction projects.

Are you looking for a reliable waterproofing solution for your next building project? Consider the advantages of steel PU sandwich panels from Weifang Sandong Building Materials Co., Ltd. Our panels are engineered to provide superior water resistance, durability, and energy efficiency. Contact us at info@sdqsc.com to learn more about how our steel PU sandwich panels can meet your specific construction needs and enhance the longevity of your building.

FAQ

How long do steel PU sandwich panels typically last?

With proper installation and maintenance, steel PU sandwich panels can last 30-40 years or more, depending on environmental conditions and usage.

Can steel PU sandwich panels be used in coastal areas?

Yes, they can be used in coastal areas. However, special coatings or treatments may be necessary to protect against salt corrosion.

Are these panels environmentally friendly?

Steel PU sandwich panels are recyclable and contribute to energy efficiency in buildings, making them a relatively eco-friendly choice.

How do I maintain the waterproofing of steel PU sandwich panels?

Regular inspections, cleaning, and prompt repairs of any damage are key to maintaining the waterproofing properties of these panels.

References

1.Building Science Corporation. (2021). "Water Management in Building Envelopes."

2.International Journal of Engineering Research and Technology. (2020). "Performance Analysis of Sandwich Panels in Construction."

3.American Society for Testing and Materials. (2019). "Standard Test Methods for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference."

4.Journal of Building Engineering. (2018). "Durability Assessment of Insulated Sandwich Panels."