Unparalleled Thermal Performance and Energy Efficiency

One of the most striking features of polyurethane sandwich PUF panels is their exceptional thermal insulation capabilities. With a remarkably low thermal conductivity of 0.018W/m.k, these panels create a formidable barrier against heat transfer. This translates to significant energy savings for industrial facilities, as the panels effectively maintain desired indoor temperatures year-round with minimal heating or cooling requirements.

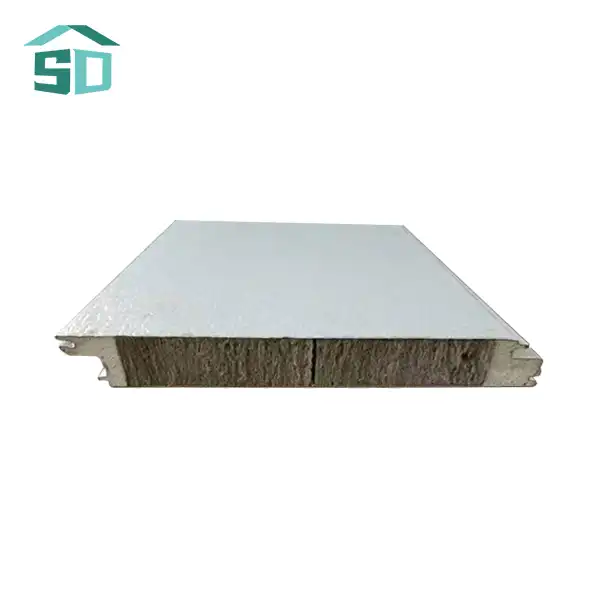

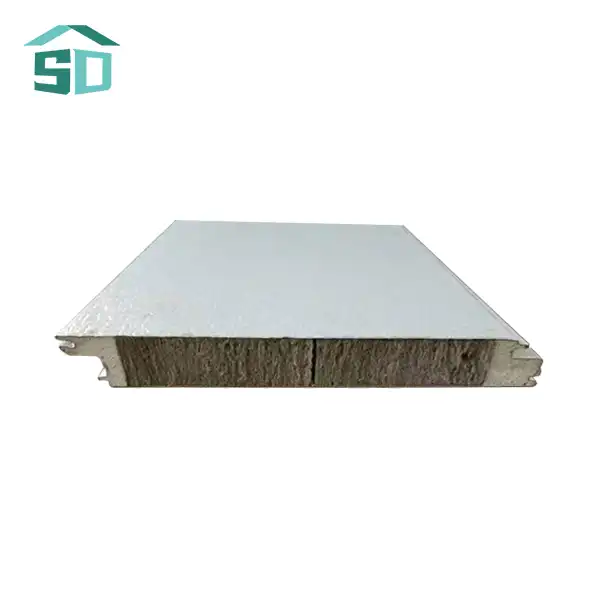

The superior insulation properties of PUF panels stem from their unique construction. The core of the panel consists of rigid polyurethane foam, which is renowned for its excellent insulating qualities. This foam core is sandwiched between two layers of durable material, typically steel or aluminum, creating a robust and highly effective insulating unit.

Reducing Energy Costs and Environmental Impact

By minimizing heat loss in winter and heat gain in summer, polyurethane sandwich PUF panels contribute to substantial reductions in energy consumption. This not only leads to lower operational costs for industrial facilities but also aligns with sustainability goals by reducing the carbon footprint associated with excessive energy use. The thermal resistance (R-value) of these panels is impressive, measuring at 2.09m2k/w, which ensures optimal temperature control even in extreme weather conditions.

Durability and Structural Integrity for Demanding Environments

Industrial settings often subject building materials to harsh conditions, from extreme temperatures to chemical exposure and high-impact scenarios. Polyurethane sandwich PUF panels are engineered to withstand these challenges, offering exceptional durability and longevity.

The panels boast a compressive strength of 52.7kpa, making them capable of withstanding significant loads without deformation. This structural integrity is crucial for industrial applications where heavy equipment or stored materials may exert pressure on walls and ceilings.

Weather Resistance and Longevity

One of the key focal points of PUF boards is their extraordinary resistance to natural components. With a waterproof rate of 0.0008, these boards give great assurance against dampness entrance, anticipating issues like form development and auxiliary debasement. Furthermore, their wind resistance of up to 8.0 Kpa guarantees steadiness indeed in ranges inclined to tall winds or extreme climate occasions.

The corrosion-resistant properties of the outer metal skins further enhance the panels' durability, making them suitable for use in coastal areas or environments with corrosive atmospheres. This combination of weather resistance and structural strength results in a building envelope that maintains its integrity and performance over many years, reducing maintenance costs and extending the lifespan of industrial structures.

Versatility and Customization for Diverse Industrial Needs

Polyurethane sandwich PUF panels offer remarkable flexibility in terms of design and application, making them suitable for a wide array of industrial projects. The panels can be customized to meet specific requirements, with options for different thicknesses, widths, and surface finishes.

For insides applications, boards are accessible in 10mm thickness, whereas outside boards come in 16mm or 20mm choices. The width can be custom-made to suit the venture needs, with outside boards ordinarily measuring 383mm wide and insides boards at 450mm. This flexibility permits for effective establishment and ideal scope in different mechanical settings.

Fire Safety and Regulatory Compliance

Security is fundamental in mechanical situations, and polyurethane sandwich PUF boards address this concern with their noteworthy fire-resistant properties. These boards meet B1/B2 fire security evaluations, giving upgraded security in the occasion of a fire. The flame-retardant characteristics of PUF boards can offer assistance moderate the spread of fire, possibly sparing lives and securing important resources in mechanical offices.

The combination of fire resistance, thermal efficiency, and structural integrity ensures that buildings constructed with these panels often meet or exceed local building codes and regulations. This compliance simplifies the approval process for new construction or retrofitting projects in the industrial sector.

Aesthetic Flexibility and Brand Integration

Whereas usefulness is vital in mechanical settings, aesthetics ought to not be ignored. Polyurethane sandwich PUF boards offer a extend of surface wraps up and colors, permitting businesses to keep up a proficient appearance or coordinated corporate branding into their building plan. The smooth, uniform surface of these boards makes a clean, advanced see that can improve the by and large appearance of mechanical offices.

The versatility of PUF panels extends to their application in various architectural styles, offering flexibility in color, texture, and finish options. Whether used in sleek, contemporary designs or more traditional industrial aesthetics, these panels can be seamlessly incorporated to achieve the desired visual impact while maintaining their superior performance characteristics, including thermal insulation, durability, and low maintenance requirements that suit diverse building types and design visions.

Conclusion

Polyurethane sandwich PUF panels represent a cutting-edge solution for industrial applications, offering an unparalleled combination of thermal efficiency, durability, and versatility. Their ability to provide outstanding insulation, withstand harsh environments, and adapt to diverse project requirements makes them an invaluable asset in modern industrial construction. As businesses continue to prioritize energy efficiency, safety, and long-term cost-effectiveness, the adoption of PUF panels is likely to grow, shaping the future of industrial building envelopes.

For more information about our high-quality polyurethane sandwich PUF panels and how they can benefit your industrial project, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.