Revolutionizing Construction with Aluminum Foam Technology

The Science Behind Aluminum Foam Sandwich Panels

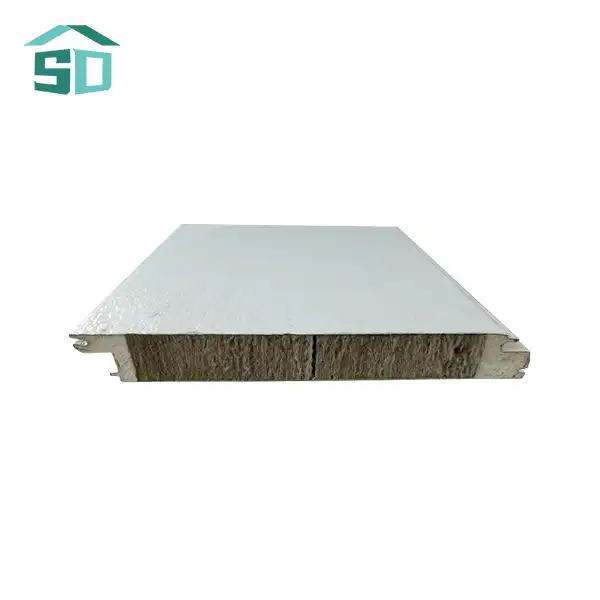

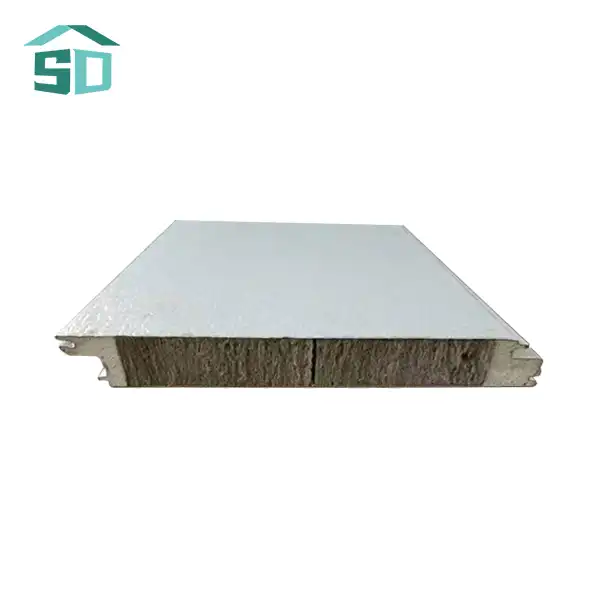

Aluminum froth sandwich boards are a wonder of materials science, combining the quality of aluminum with the one of a kind properties of froth structures. The center of these boards is made through a specialized handle that presents gas bubbles into liquid aluminum, coming about in a permeable, foam-like structure. This froth center is at that point fortified between two strong aluminum sheets, making a sandwich-like setup.

The resulting material possesses several advantageous characteristics. The foam core provides excellent thermal insulation, with a thermal conductivity of just 0.018W/m.k. This low thermal conductivity translates to superior energy efficiency in buildings, helping to maintain comfortable interior temperatures while reducing heating and cooling costs. Additionally, the structure of the foam core contributes to the panel's impressive sound dampening capabilities, making it an excellent choice for applications where noise reduction is crucial.

Unmatched Strength-to-Weight Ratio

One of the most remarkable features of aluminum foam sandwich panels is their exceptional strength-to-weight ratio. Despite their lightweight nature, these panels exhibit impressive compressive strength, measured at 52.7kpa. This combination of low weight and high strength makes them ideal for a wide range of applications, from aerospace to architecture.

The one of a kind structure of the aluminum froth center permits for proficient dissemination of loads over the board, coming about in prevalent resistance to twisting and buckling. This property is especially important in development, where materials must withstand different stresses whereas minimizing the by and large weight of the structure. The panels' wind resistance of 8.0 Kpa assist underscores their toughness and reasonableness for outside applications.

Versatility and Customization in Design

Adaptability to Various Architectural Styles

Aluminum foam sandwich panels offer architects and designers unprecedented flexibility in creating visually striking and functionally superior structures. These panels can be easily customized to suit a wide range of architectural styles, from sleek modern designs to more traditional aesthetics. The ability to tailor colors and patterns allows for seamless integration with existing design elements or the creation of bold, statement-making facades.

The panels are available in various dimensions to accommodate different project requirements. Interior panels typically have a thickness of 10mm, while exterior panels come in 16mm or 20mm thicknesses. The width of exterior panels is typically 383mm, while interior panels measure 450mm in width. This range of sizes enables designers to optimize panel usage for specific applications, minimizing waste and improving overall project efficiency.

Versatile Applications in Construction

The versatility of aluminum foam sandwich panels extends beyond their aesthetic customization. These panels are suitable for both interior and exterior wall decorations, offering a unified design solution throughout a building. Their lightweight nature makes them particularly advantageous for renovation projects, where the existing structure may have weight limitations.

In exterior applications, the panels' weather-resistant properties come to the fore. With a waterproof rate of 0.0008, they provide excellent protection against moisture infiltration, ensuring long-lasting performance even in challenging environmental conditions. The corrosion-resistant nature of aluminum further enhances the panels' durability, maintaining their appearance and structural integrity over time.

Sustainability and Safety: Key Considerations in Modern Construction

Eco-Friendly Credentials

As the construction industry increasingly prioritizes sustainability, aluminum foam sandwich panels emerge as an environmentally responsible choice. The production process of these panels is designed to minimize waste and energy consumption. Furthermore, aluminum is a highly recyclable material, allowing for efficient resource utilization at the end of the panels' lifecycle.

The energy-saving properties of aluminum foam sandwich panels also contribute to their eco-friendly profile. Their excellent thermal insulation capabilities can significantly reduce a building's energy consumption for heating and cooling, leading to lower carbon emissions over the structure's lifetime. This combination of sustainable production and energy efficiency makes these panels an attractive option for green building projects.

Fire Safety and Building Code Compliance

Safety is paramount in construction, and aluminum foam sandwich panels excel in this regard, particularly in terms of fire resistance. These panels boast a fire-protection rating of B1/B2, indicating their ability to resist fire spread and maintain structural integrity under high temperatures. This characteristic is crucial for ensuring occupant safety and complying with stringent building codes.

The non-flammable nature of aluminum further enhances the panels' fire safety profile. In the event of a fire, these panels do not contribute to the spread of flames or the release of toxic fumes, providing valuable time for evacuation and firefighting efforts. This combination of fire resistance and overall safety makes aluminum foam sandwich panels an ideal choice for a wide range of building types, from residential complexes to commercial and industrial structures.

Cost-Effectiveness and Long-Term Value

While the initial cost of aluminum foam sandwich panels may be higher than some traditional building materials, their long-term value proposition is compelling. The durability and low maintenance requirements of these panels translate to reduced lifecycle costs. Their energy-saving properties contribute to ongoing operational cost reductions, making them an economically sound choice for forward-thinking developers and building owners.

Moreover, the versatility and aesthetic appeal of aluminum foam sandwich panels can enhance a property's value. The ability to create striking architectural designs with these panels can increase a building's marketability and prestige, potentially leading to higher rental or resale values. When considering the total cost of ownership, including installation, maintenance, energy savings, and potential value appreciation, aluminum foam sandwich panels often emerge as a cost-effective solution for modern construction projects.

Conclusion

Aluminum foam sandwich panels represent a significant leap forward in construction materials, offering a unique combination of lightweight design, durability, and versatility. Their impressive thermal properties, fire resistance, and customizable aesthetics make them an ideal choice for a wide range of architectural applications. As the construction industry continues to evolve towards more sustainable and efficient practices, these innovative panels are poised to play an increasingly important role in shaping the buildings of the future.

For those interested in exploring the possibilities of aluminum foam sandwich panels for their next project, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products. To learn more about our exterior cladding and facade solutions, including aluminum foam sandwich panels, please contact us at info@sdqsc.com. Our team is ready to assist you in elevating your construction projects with cutting-edge materials that combine performance, aesthetics, and sustainability.