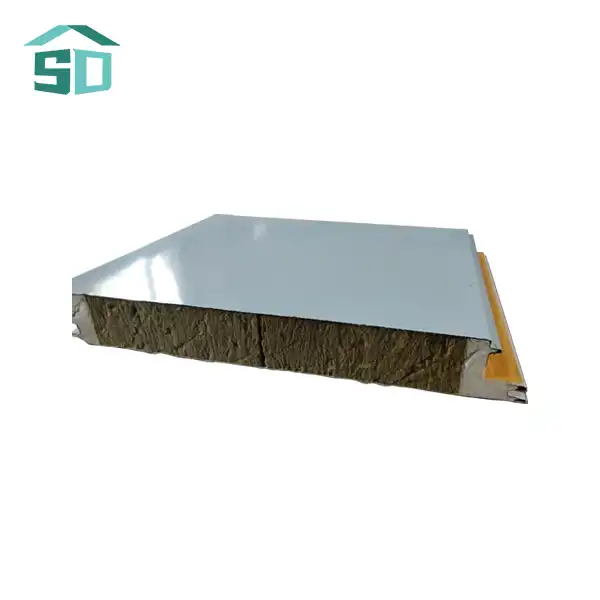

Comprehending the Safety Features of PU Insulation Panels

Fire Resistance Properties

One of the primary safety concerns with any building material is its fire resistance. PU insulation panels excel in this aspect, boasting a fire-protection rating of B1/B2. This classification indicates that the panels have undergone rigorous testing and meet high standards for fire safety. The fire-resistant properties of PU insulation panels provide crucial minutes for evacuation in case of a fire, making them a responsible choice for both residential and commercial buildings.

The fire resistance of PU insulation panels is not just about meeting regulatory requirements; it's about providing peace of mind to building occupants. These panels are designed to resist flame spread and smoke development, contributing to overall building safety. It's worth noting that the exact fire performance can vary depending on the specific formulation and thickness of the panel, so it's essential to choose panels that meet or exceed local building codes and safety standards.

Moisture Resistance and Indoor Air Quality

Safety in building materials extends beyond fire resistance to include factors that affect long-term health and well-being. PU insulation panels shine in this area as well, with an impressive waterproof rate of 0.0008. This exceptional moisture resistance is crucial for preventing water infiltration, which can lead to mold growth and structural damage over time.

The moisture-resistant nature of PU insulation panels contributes significantly to maintaining good indoor air quality. By effectively blocking moisture, these panels help create a barrier against mold, mildew, and other harmful microorganisms that thrive in damp environments. This not only protects the structural integrity of the building but also safeguards the health of its occupants, particularly those with respiratory issues or allergies.

Durability and Long-Term Performance

The safety of a building material is not just about its immediate properties but also its ability to maintain those properties over time. PU insulation panels are engineered for durability, with resistance to weathering, corrosion, and UV damage. This longevity ensures that the safety features of the panels remain effective throughout the life of the building.

With a compressive strength of 52.7kpa, PU insulation panels can withstand significant pressure without compromising their structure or insulative properties. This strength contributes to the overall stability and safety of the building envelope. Additionally, the panels' resistance to UV damage means they maintain their integrity even when exposed to sunlight, preventing degradation that could compromise their safety features over time.

Environmental Safety and Sustainability of PU Insulation Panels

Energy Efficiency and Carbon Footprint Reduction

When discussing the safety of building materials, it's crucial to consider their environmental impact. PU insulation panels contribute positively to environmental safety by significantly improving energy efficiency in buildings. With a thermal conductivity of 0.018W/m.k and a thermal resistance of 2.09m2k/w, these panels provide superior insulation, reducing the energy required for heating and cooling.

This enhanced energy efficiency translates to a reduced carbon footprint for buildings equipped with PU insulation panels. By minimizing energy consumption, these panels help decrease greenhouse gas emissions associated with heating and cooling systems. This aspect of environmental safety is increasingly important as we face global challenges related to climate change and energy conservation.

Eco-Friendly Manufacturing Processes

The safety of PU insulation panels extends to their production process. Many manufacturers are adopting eco-friendly practices in the creation of these panels, using sustainable materials and reducing waste. Some companies are even incorporating recycled materials into their PU foam formulations, further enhancing the panels' environmental credentials.

Additionally, the lightweight nature of PU insulation panels (with thicknesses ranging from 10mm for interior applications to 16mm/20mm for exterior use) means less material is required compared to traditional insulation methods. This not only reduces the environmental impact of transportation but also minimizes the overall resource consumption in building construction.

Long Lifespan and Reduced Waste

The durability of PU insulation panels contributes to their environmental safety by reducing the need for frequent replacements. With proper installation and maintenance, these panels can last for decades, minimizing construction waste and the environmental impact associated with manufacturing and disposing of building materials.

Furthermore, at the end of their useful life, many PU insulation panels can be recycled or repurposed, further reducing their environmental footprint. This closed-loop approach to building materials aligns with principles of sustainable construction and circular economy practices.

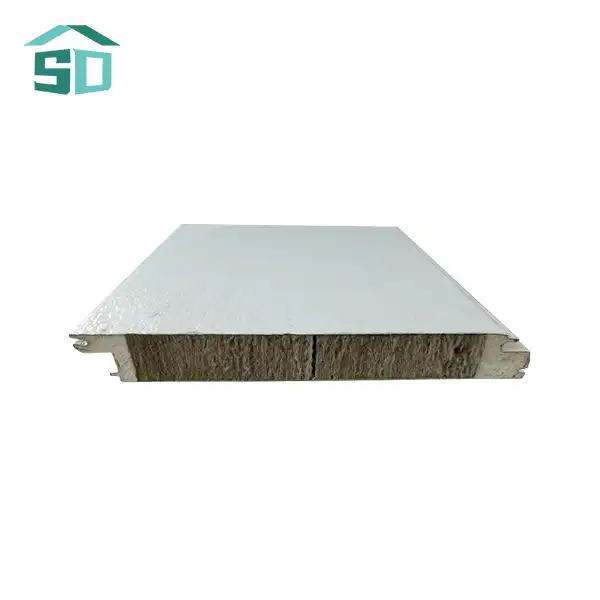

Installation and Maintenance Safety Considerations

Professional Installation for Optimal Safety

While PU insulation panels are inherently safe, proper installation is crucial to ensure they perform as intended. Professional installation ensures that the panels are correctly fitted, with appropriate sealing and fastening techniques. This not only maximizes the panels' insulative properties but also ensures that fire resistance and moisture barrier capabilities are not compromised.

Installers should follow manufacturer guidelines and local building codes meticulously. For example, the wind resistance rating of 8.0 Kpa indicates that these panels can withstand significant wind loads, but only if they are installed correctly. Professional installers understand how to secure the panels to achieve this level of performance, particularly important for exterior applications.

Safe Handling During Installation

Safety during the installation process is also paramount. PU insulation panels are lightweight, with widths of 383mm for exterior and 450mm for interior applications, making them easier to handle than some traditional insulation materials. However, proper personal protective equipment (PPE) should still be used, including gloves, eye protection, and dust masks when cutting or modifying panels.

The thickness of surface materials (ranging from 0.23mm to 0.27mm) provides a durable exterior, but care should be taken during handling to prevent damage that could compromise the panel's performance. Installers should be trained in safe cutting techniques and proper disposal of any waste materials.

Maintenance for Long-Term Safety

Once installed, PU insulation panels require minimal maintenance to maintain their safety features. Regular inspections can help identify any potential issues early, such as damaged seals or fasteners that may affect the panel's moisture resistance or insulative properties. In the rare event that a panel needs replacement, it can typically be done without disturbing surrounding panels, minimizing disruption and maintaining the overall integrity of the insulation system.

It's important to note that while PU insulation panels are resistant to many environmental factors, they should be protected from excessive physical damage. In high-traffic areas or where impact is likely, additional protective measures may be necessary to ensure the long-term safety and performance of the panels.

Conclusion

PU insulation panels offer a safe, efficient, and sustainable solution for building insulation. Their fire resistance, moisture protection, and durability contribute to both immediate and long-term safety for building occupants. When properly installed and maintained, these panels not only enhance the energy efficiency of buildings but also contribute to healthier indoor environments and reduced environmental impact.

As with any building material, it's crucial to choose high-quality PU insulation panels from reputable manufacturers and ensure professional installation. By doing so, builders and property owners can confidently leverage the numerous safety benefits these innovative panels provide.

For more information about PU insulation panels and their applications in your construction projects, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in selecting the right insulation solution for your specific needs, ensuring safety, efficiency, and sustainability in your building endeavors.