Unparalleled Thermal Performance and Energy Efficiency

Superior Heat and Cold Barrier

Rockwool sandwich panels excel in providing exceptional thermal insulation. The rockwool core, composed of tightly packed mineral fibers, creates a formidable barrier against heat transfer. This unique structure effectively minimizes thermal bridging, a common issue in traditional insulation methods. As a result, buildings equipped with rockwool sandwich panels maintain a stable indoor temperature, reducing the need for excessive heating or cooling. This thermal stability translates into significant energy savings for property owners and contributes to a more comfortable living or working environment.

Year-Round Climate Control

The remarkable insulation properties of rockwool sandwich panels ensure optimal performance in both hot and cold climates. During summer months, these panels prevent heat from penetrating the building envelope, keeping interiors cool and reducing the load on air conditioning systems. In winter, they retain indoor heat, minimizing heat loss and lowering heating costs. This year-round efficiency makes rockwool sandwich panels an ideal choice for regions with diverse climate conditions, offering consistent performance regardless of seasonal changes.

Long-Term Energy Savings

Investing in rockwool sandwich panels pays dividends in the long run through substantial energy savings. The high thermal resistance (R-value) of these panels ensures that buildings maintain their insulation efficiency over time. Unlike some insulation materials that may settle or degrade, rockwool retains its structure and performance for the life of the building. This long-lasting effectiveness translates into consistent energy savings, lower utility bills, and a reduced carbon footprint for the entire lifespan of the structure.

Enhanced Safety and Durability Features

Fire-Resistant Properties

One of the standout features of rockwool sandwich panels is their exceptional fire resistance. Rockwool, also known as stone wool, is naturally non-combustible and can withstand temperatures up to 1000°C (1832°F). This inherent fire resistance provides crucial protection in the event of a fire, slowing its spread and allowing more time for evacuation. The panels' Class A1 fire rating, the highest possible classification, offers peace of mind to building owners and occupants alike. This fire-resistant quality makes rockwool sandwich panels particularly suitable for high-risk environments such as industrial facilities, healthcare buildings, and multi-story structures.

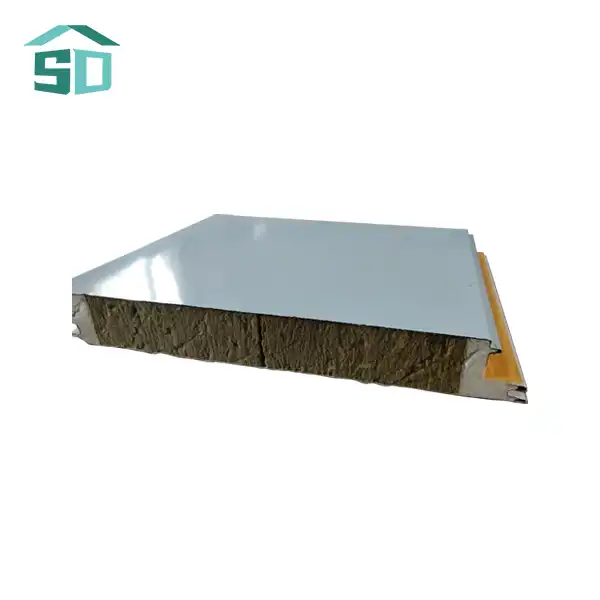

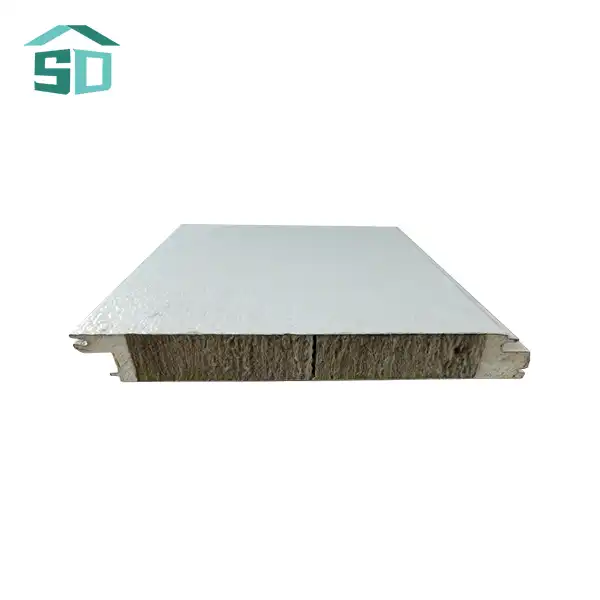

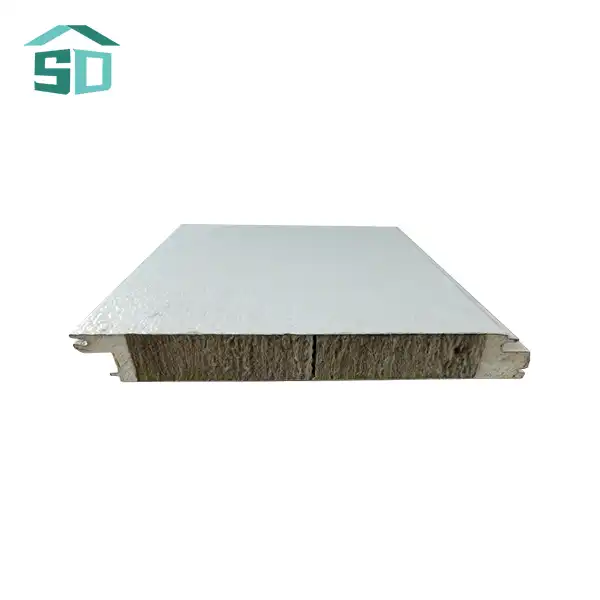

Moisture and Corrosion Resistance

Rockwool sandwich panels are engineered to withstand harsh environmental conditions. The rockwool core is naturally water-repellent, preventing moisture absorption and the associated problems of mold growth and structural damage. This moisture resistance also contributes to the panels' ability to maintain their insulation properties over time. Additionally, the metal facings of the panels can be treated with corrosion-resistant coatings, ensuring longevity even in coastal or industrial areas where corrosive elements are prevalent. This combination of moisture and corrosion resistance significantly extends the lifespan of the building envelope, reducing maintenance costs and preserving the structure's integrity.

Acoustic Performance

Past warm separator, rockwool sandwich boards offer fabulous sound retention properties. The thick fiber structure of rockwool viably hoses sound waves, diminishing clamor transmission between rooms or from outside sources. This acoustic cover is especially important in commercial buildings, instructive educate, and private complexes where sound control is basic for consolation and protection. The double advantage of warm and acoustic cover makes rockwool sandwich boards a comprehensive arrangement for making comfortable, energy-efficient, and calm insides spaces.

Versatility and Aesthetic Appeal

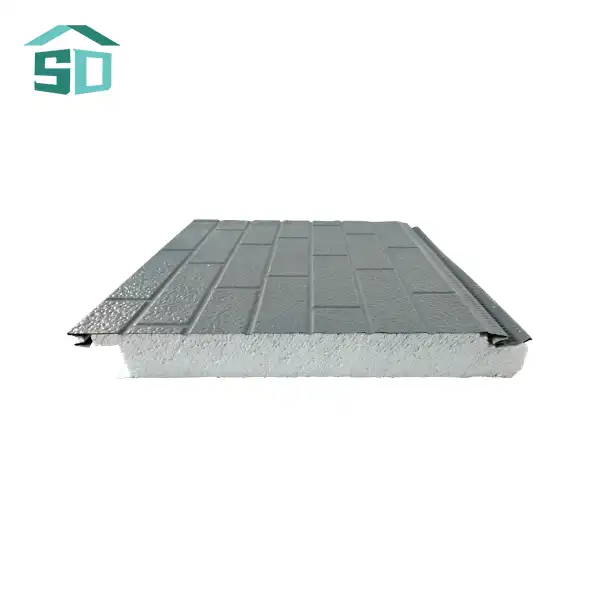

Customizable Design Options

Rockwool sandwich boards offer surprising adaptability in terms of plan and aesthetics. Accessible in a wide run of colors, wraps up, and surfaces, these boards can be custom-made to complement any building fashion or brand personality. The capacity to customize board sizes and thicknesses permits for consistent integration into different building plans, from smooth advanced exteriors to more conventional appearances. This flexibility engages planners and architects to accomplish their imaginative vision without compromising on cover execution or basic keenness.

Easy Installation and Maintenance

The lightweight nature of rockwool sandwich panels significantly simplifies the installation process. Their design allows for quick and efficient mounting, reducing labor costs and construction time. The panels can be easily cut and shaped on-site to accommodate irregular surfaces or special architectural features. This ease of installation makes rockwool sandwich panels an attractive option for both new construction and retrofit projects. Moreover, their durable construction and resistance to environmental factors minimize the need for frequent maintenance, further reducing long-term costs for building owners.

Sustainable Building Solution

As the construction industry increasingly focuses on sustainability, rockwool sandwich panels emerge as an eco-friendly choice. The rockwool core is manufactured from abundant natural materials and can contain a high percentage of recycled content. At the end of their life cycle, these panels can be recycled, contributing to a circular economy in the construction sector. The energy-saving properties of rockwool sandwich panels also play a significant role in reducing a building's overall environmental impact by lowering energy consumption and associated carbon emissions. This combination of recyclability and energy efficiency makes rockwool sandwich panels a preferred choice for green building projects and LEED certifications.

Conclusion

Rockwool sandwich panels represent a pinnacle in insulation technology, offering an unparalleled combination of thermal efficiency, fire safety, durability, and design flexibility. Their ability to significantly reduce energy costs while enhancing building safety and comfort makes them an ideal choice for a wide range of construction projects.

As the building industry continues to evolve towards more sustainable and efficient solutions, rockwool sandwich panels stand out as a forward-thinking option that meets both current needs and future challenges in building insulation. For more information about our rockwool sandwich panels and how they can benefit your next construction project, please contact us at info@sdqsc.com. Our team of experts is ready to help you find the perfect insulation solution for your specific needs.