Unmatched Durability and Strength: The Foundation of PU Sandwich Panels

Structural Integrity That Stands the Test of Time

PU sandwich panels for walls for walls boast exceptional structural integrity, thanks to their unique composition. The polyurethane core, sandwiched between two rigid facing materials, creates a remarkably strong and stable structure. This innovative design allows the panels to withstand significant loads and resist deformation, ensuring long-term reliability in various construction applications.

The strength-to-weight ratio of PU sandwich panels is particularly impressive. Despite their lightweight nature, these panels can support substantial loads, making them ideal for both load-bearing and non-load-bearing wall applications. This characteristic not only enhances the overall structural stability of buildings but also simplifies the construction process, reducing the need for additional support structures.

Weather Resistance: A Shield Against the Elements

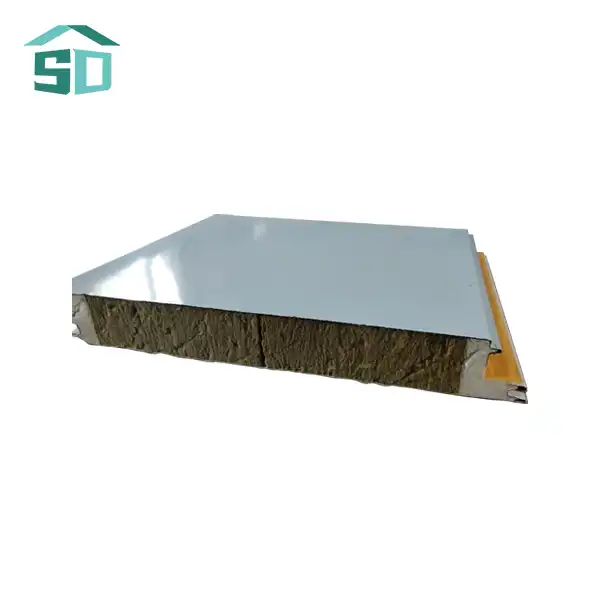

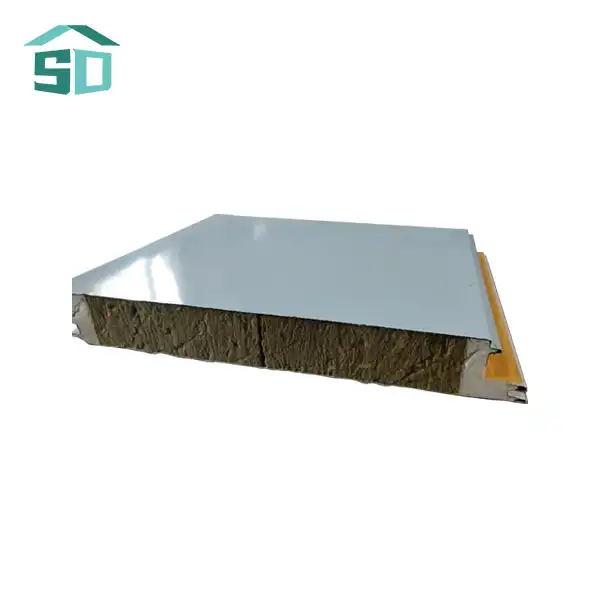

One of the key advantages of PU sandwich panels for walls is their exceptional weather resistance. The exterior facings of these panels are typically made from materials such as aluminum, steel, stainless steel, or copper, which are inherently resistant to corrosion and weathering. These materials are further enhanced with protective coatings or treatments, ensuring that the panels maintain their integrity and appearance even in harsh environmental conditions.

The polyurethane core itself is impervious to moisture, preventing water ingress and the associated problems of mold, mildew, and structural deterioration. This moisture resistance not only protects the internal structure of the building but also contributes to a healthier indoor environment. The panels' ability to withstand temperature fluctuations, UV radiation, and other environmental stressors makes them an excellent choice for exterior wall applications in diverse climates.

Superior Thermal Efficiency: Revolutionizing Energy Conservation in Buildings

Advanced Insulation Technology

The thermal efficiency of PU sandwich panels is one of their most significant advantages in wall construction. The polyurethane core serves as an excellent insulator, significantly reducing heat transfer between the interior and exterior of a building. This high-performance insulation is due to the closed-cell structure of polyurethane foam, which traps air and creates a barrier against thermal conductivity.

The insulation properties of PU sandwich panels for walls are quantified by their R-value, which measures thermal resistance. These panels typically offer R-values that are substantially higher than traditional building materials, even at relatively thin thicknesses. This superior insulation performance translates to reduced heating and cooling costs, making PU sandwich panels an economically sound choice for long-term energy efficiency.

Year-Round Comfort and Energy Savings

The exceptional thermal performance of PU sandwich panels contributes to year-round comfort in buildings. During summer months, the panels effectively block heat from entering the interior, reducing the load on air conditioning systems. In winter, they prevent heat loss, maintaining a warm and cozy indoor environment while minimizing heating requirements.

This consistent thermal regulation not only enhances occupant comfort but also leads to substantial energy savings. Buildings constructed with PU sandwich panels often see a marked reduction in their energy consumption, which translates to lower utility bills and a reduced carbon footprint. The energy-efficient nature of these panels aligns perfectly with modern green building standards and can contribute to achieving certifications such as LEED (Leadership in Energy and Environmental Design).

Versatility and Customization: Adapting to Diverse Architectural Needs

Flexible Design Options

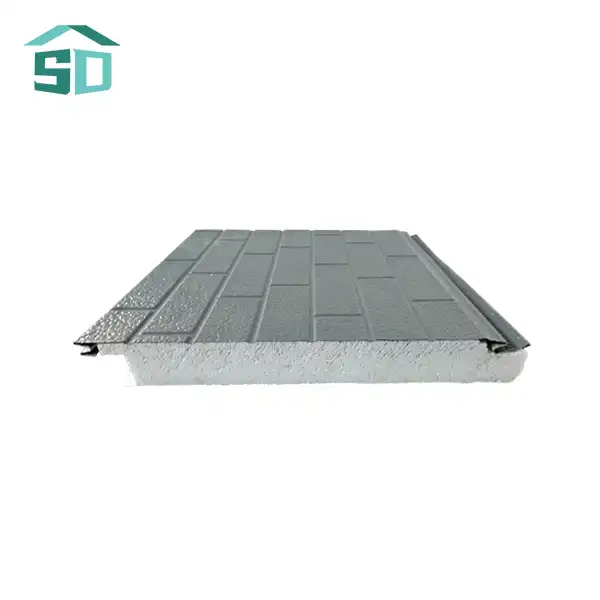

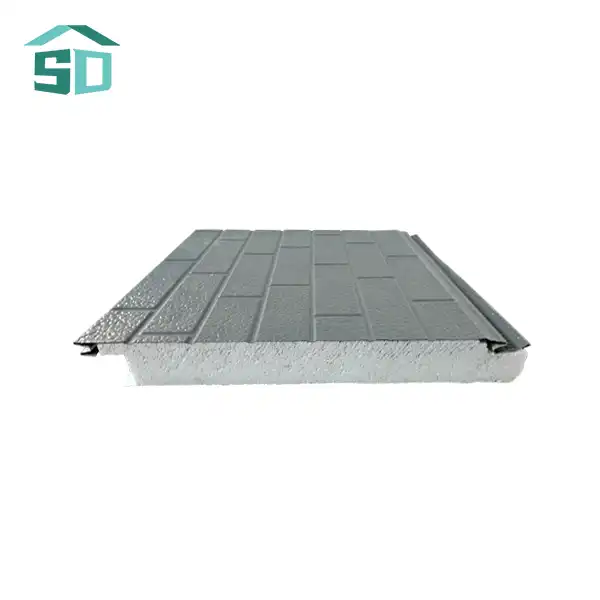

PU sandwich panels for walls offer remarkable versatility in terms of design and application. They are available in a wide range of thicknesses, typically from 50mm to 200mm, allowing architects and builders to select the optimal panel size for specific project requirements. This flexibility extends to the choice of facing materials, with options including aluminum, steel, stainless steel, and copper, each offering unique aesthetic and functional properties.

The customization options for PU sandwich panels are extensive. They can be manufactured in various colors through coating, painting, or anodizing processes, enabling architects to achieve their desired visual effect. The panels can also be produced with different surface textures and patterns, further expanding the design possibilities. This level of customization allows for seamless integration with diverse architectural styles, from sleek modern designs to more traditional aesthetics.

Adaptability Across Construction Projects

The versatility of PU sandwich panels makes them suitable for a wide range of construction projects. They excel in both interior and exterior wall applications, offering consistent performance and aesthetics throughout a building. These panels are equally at home in residential complexes, office buildings, industrial facilities, and specialized structures like security kiosks or historic building renovations.

Their adaptability is further enhanced by the ease of installation. PU sandwich panels for walls can be quickly and efficiently erected, reducing construction time and labor costs. This characteristic makes them particularly valuable in projects with tight deadlines or in situations where minimizing disruption is crucial, such as renovations of occupied buildings.

The combination of strength, insulation, and design flexibility positions PU sandwich panels as an ideal solution for modern construction challenges. They offer architects and builders the tools to create energy-efficient, durable, and visually appealing structures that meet the diverse needs of today's building industry.

Conclusion

PU sandwich panels for walls represent a significant advancement in building technology, offering a unique combination of strength, thermal efficiency, and design flexibility. Their superior insulation properties contribute to substantial energy savings, while their durability ensures long-lasting performance in various environmental conditions. The versatility of these panels makes them suitable for a wide range of architectural applications, from residential to commercial and industrial projects.

As the construction industry continues to evolve towards more sustainable and efficient practices, PU sandwich panels stand out as a solution that meets both current needs and future challenges. Their ability to enhance building performance while offering aesthetic versatility makes them an invaluable tool for architects, builders, and property owners alike.

For those seeking to leverage the benefits of PU sandwich panels in their next construction project, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products. To learn more about our range of exterior cladding and facade solutions, including PU sandwich panels, please contact us at info@sdqsc.com. Our team is ready to help you find the perfect solution for your building needs, ensuring optimal performance, energy efficiency, and aesthetic appeal.