The Unmatched Durability of Fibreglass Sandwich Panels

Fibreglass sandwich panels have greatly advanced the construction industry because of their durability and long lifespan. Unlike plastic, which can degrade over time, fibreglass retains its structural integrity and shape for extended periods, making it suitable for both interior and exterior wall applications. Their robust construction enables them to endure harsh environmental conditions—including extreme temperatures, high humidity, and prolonged sunlight—while maintaining consistent, reliable performance.

One of the key factors contributing to the durability of fibreglass sandwich panels is their corrosion-proof design. This inherent resistance to corrosion ensures that the panels maintain their strength and appearance even when exposed to aggressive chemicals or saltwater environments. Such resilience makes fibreglass panels particularly suitable for coastal constructions or industrial facilities where corrosive elements are present.

Long-Term Cost-Effectiveness

Although fibreglass sandwich panels may cost more upfront compared to certain plastic options, they offer clear long-term value. Because they are strong, durable, and require little upkeep, these panels help lower repair and replacement expenses over time, making them an economical and wise option in the long term. The exceptional durability of fibreglass translates to reduced maintenance costs and extended service life, ultimately providing a better return on investment. Moreover, the energy-saving properties of these panels contribute to lower operational costs over the building's lifetime.

Customizable Dimensions for Versatile Applications

Fibreglass sandwich panels exhibit outstanding flexibility in dimensions and customization, rendering them highly adaptable across various construction and industrial applications. Panel thickness usually falls between 50mm and 100mm but can sometimes be thicker depending on the situation. Lengths can reach up to 12 meters, allowing for versatile sizing options. This array of options ensures that the panels can be accurately and easily adjusted to meet the unique requirements of different projects. Additionally, standard width options between 1,200mm and 1,500mm offer substantial surface coverage, effectively minimizing both installation time and overall labor costs.

Superior Insulation and Energy Efficiency

One of the most significant advantages of fibreglass sandwich panels over plastic alternatives is their exceptional insulation properties. The thermal conductivity of these panels varies between 0.022 and 0.045 W/m·K, depending on the type of insulation material used at the core. This range allows for different levels of thermal performance to match specific energy efficiency needs. This low thermal conductivity translates to superior energy efficiency, helping to maintain comfortable indoor temperatures while reducing heating and cooling costs.

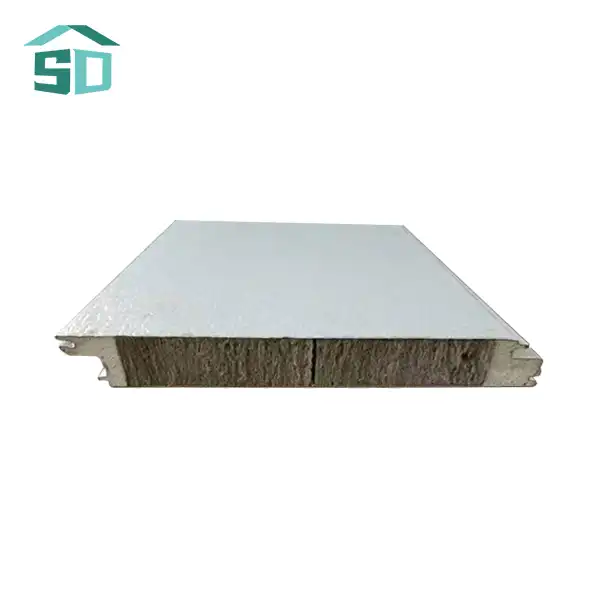

The insulation core of fibreglass sandwich panels can be customized to suit specific requirements. Options include polyurethane (PU), polystyrene (EPS), rock wool, and glass wool. Each of these materials offers unique benefits in terms of thermal performance, sound insulation, and fire resistance. This versatility allows architects and builders to select the most appropriate insulation core for their specific project needs.

Enhanced Acoustic Performance

Beyond thermal insulation, fibreglass sandwich panels demonstrate notable excellence in sound insulation. Their layered structure collaborates with the noise-absorbing properties of the insulation core, effectively minimizing noise transmission between different areas. This feature renders them highly practical in environments where sound level management is essential. Such acoustic performance holds particular significance in commercial buildings, educational facilities, and residential communities, where controlling noise is vital to ensuring occupant comfort.

Year-Round Comfort and Energy Savings

The superior insulation properties of fibreglass sandwich panels contribute to year-round comfort in buildings. By effectively reducing heat transfer, these panels help maintain stable indoor temperatures regardless of external conditions. This thermal stability not only enhances occupant comfort but also leads to significant energy savings by reducing the load on HVAC systems.

Fire Safety and Environmental Considerations

When it comes to fire safety, fibreglass sandwich panels outperform many plastic materials. These panels are available in Class A or B fire resistance ratings, providing crucial protection in the event of a fire. The inherent flame-retardant properties of fibreglass, combined with specially formulated insulation cores, contribute to slower fire spread and reduced smoke generation, potentially saving lives and property.

Moreover, fibreglass sandwich panels represent an eco-conscious choice for sustainable construction. The long lifespan of these panels reduces the need for frequent replacements, minimizing waste and resource consumption. Additionally, many components of fibreglass panels can be recycled at the end of their service life, further reducing their environmental impact.

Aesthetic Versatility and Design Freedom

Fibreglass sandwich panels offer unparalleled aesthetic versatility, allowing architects and designers to achieve their desired visual outcomes. These panels are available with various surface finishes, including gelcoat, smooth, or textured options. Furthermore, custom RAL colors can be applied to match specific design schemes or brand identities. This customization potential enables the creation of visually striking facades that enhance the overall architectural appeal of buildings.

Compliance with Building Codes and Standards

Fibreglass sandwich panels are produced to adhere to strict building codes and industry standards. During manufacturing, rigorous quality control procedures are implemented to guarantee uniform performance and dependability. This adherence to established norms offers assurance to builders, architects, and property owners, as they can be confident that the materials incorporated into their projects meet or surpass regulatory expectations.

Conclusion

The superiority of fiberglass over plastic in construction applications, particularly in the form of fibreglass sandwich panels, is evident across multiple dimensions. From unmatched durability and superior insulation to enhanced fire safety and aesthetic versatility, fibreglass offers a comprehensive solution for modern building needs. As the construction industry continues to evolve towards more sustainable and efficient practices, fibreglass sandwich panels stand out as a forward-thinking choice for architects, builders, and property owners alike.

For more information about exterior cladding and facade solutions, including fibreglass sandwich panels, please contact us at info@sdqsc.com. Our team of experts at Weifang Sandong Building Materials Co., Ltd. is ready to assist you in finding the perfect solution for your construction needs.