The Unparalleled Benefits of Metal Insulated Sandwich Panels in Industrial Construction

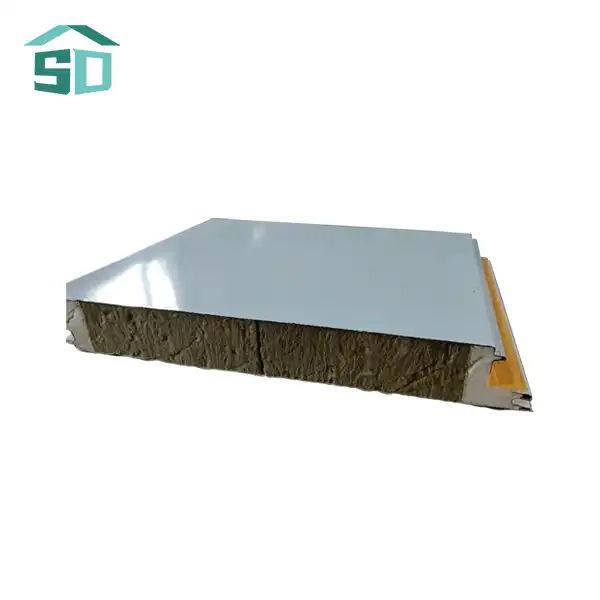

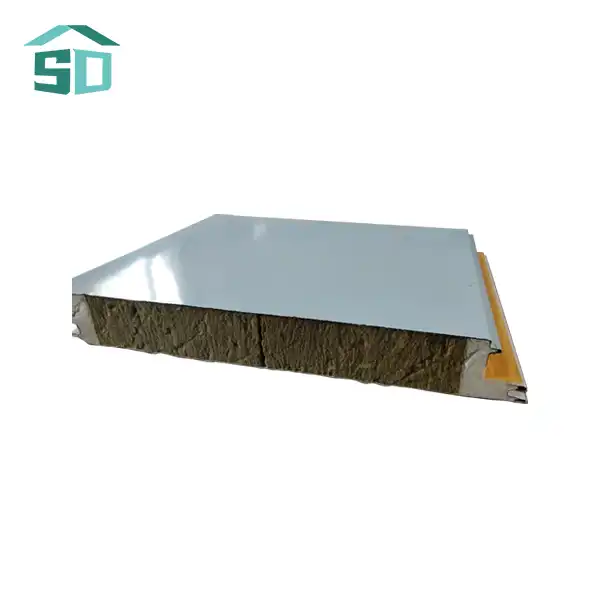

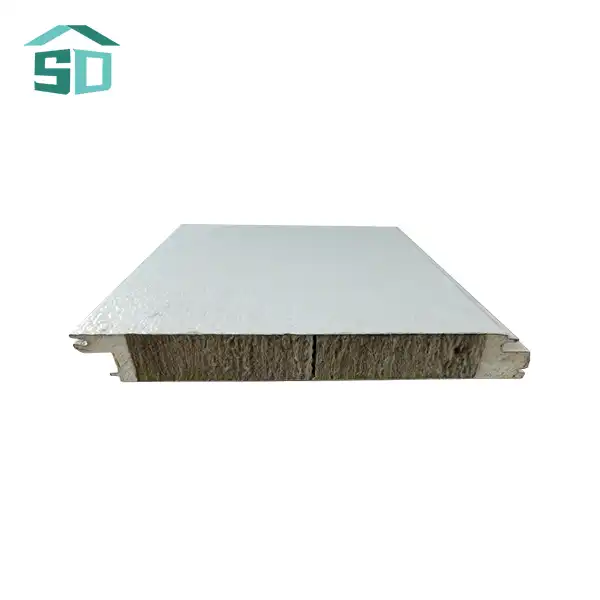

Metal insulated sandwich panels have become the backbone of industrial construction, offering a myriad of advantages that traditional building materials simply can't match. At the heart of their popularity lies their exceptional insulation properties. These panels typically feature a polyurethane (PU) or polyisocyanurate (PIR) core, sandwiched between two metal sheets, resulting in a thermal conductivity as low as 0.018 W/m.K. This remarkable insulation capacity translates to significant energy savings, as it helps maintain ideal temperatures within industrial spaces, reducing the load on HVAC systems and, consequently, operational costs.

The durability of metal insulated sandwich panels is another crucial factor driving their adoption in industrial settings. With a metal construction that ensures longevity and strength, these panels can withstand the rigors of industrial environments. Their corrosion-proof design protects against rust and weathering, making them ideal for facilities exposed to harsh conditions. The panels boast impressive wind resistance of up to 8.0 Kpa, ensuring structural integrity even in high-wind scenarios.

Safety is paramount in industrial buildings, and metal insulated sandwich panels excel in this aspect as well. They come with fire safety certifications, typically achieving a B1/B2 fire-protection rating. This non-combustible nature provides an added layer of security, crucial for industrial facilities where fire hazards can be a significant concern. The panels' fire-resistant properties contribute to creating safer work environments and can potentially lower insurance premiums for businesses.

Customization and Versatility: Adapting to Diverse Industrial Needs

One of the most compelling features of metal insulated sandwich panels is their adaptability to various industrial applications. These panels come in a range of thicknesses and widths to suit different requirements. For instance, exterior panels are available in thicknesses of 16mm or 20mm with a width of 383mm, while interior panels can be 10mm thick with a width of 450mm. This flexibility allows architects and builders to tailor the panels to specific project needs, whether for walls, roofs, or partitions.

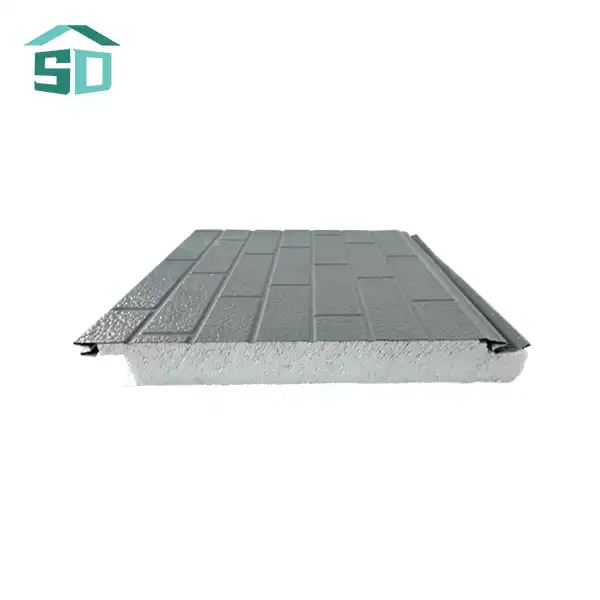

The aesthetic versatility of metal insulated sandwich panels is equally impressive. Industrial facilities no longer need to compromise on appearance for functionality. These panels come in a wide array of colors and patterns, allowing businesses to create visually appealing structures that align with their brand identity. This customization extends to both interior and exterior applications, enabling cohesive design schemes throughout the facility.

Moreover, the versatility of metal insulated sandwich panels extends beyond just industrial buildings. They find applications in a variety of construction projects, including residential complexes, offices, villas, gardens, historic building renovations, municipal buildings, and even security kiosks. This wide-ranging applicability speaks to the panels' adaptability and universal appeal in the construction industry.

Sustainable and Cost-Effective: The Economic Advantages of Metal Insulated Sandwich Panels

In an era where sustainability is no longer optional but essential, metal insulated sandwich panels offer a compelling eco-friendly solution for industrial construction. These panels are often manufactured using sustainable materials, reducing the environmental impact of building projects. Their superior insulation properties contribute significantly to energy conservation, aligning with global efforts to reduce carbon footprints in the industrial sector.

The eco-friendliness of metal insulated sandwich panels extends beyond their operational phase. Their durability means they require less frequent replacement, reducing waste and the need for new materials over time. Additionally, many of these panels are recyclable at the end of their lifecycle, further minimizing their environmental impact.

From an economic perspective, metal insulated sandwich panels present a cost-effective choice for industrial buildings. While the initial investment might be higher compared to some traditional materials, the long-term savings are substantial. The energy efficiency they provide translates to lower utility costs over the building's lifetime. Their durability reduces maintenance and replacement expenses, contributing to a lower total cost of ownership.

Furthermore, the ease and speed of installation associated with metal insulated sandwich panels can significantly reduce construction time and labor costs. This efficiency is particularly valuable in industrial projects where time is often of the essence. The panels' lightweight nature also means less stress on the building's foundation, potentially reducing structural costs.

Performance Metrics: Quantifying the Superiority of Metal Insulated Sandwich Panels

The superiority of metal insulated sandwich panels in industrial applications is not just anecdotal; it's backed by impressive performance metrics. With a thermal resistance of 2.09m2k/w, these panels provide exceptional insulation, far surpassing many traditional building materials. Their waterproof rate of 0.0008 ensures excellent protection against moisture intrusion, a critical factor in many industrial environments.

The panels' compressive strength of 52.7kpa demonstrates their ability to withstand significant loads, making them suitable for a wide range of industrial applications. This structural integrity, combined with their fire resistance and durability, makes metal insulated sandwich panels a comprehensive solution for industrial building needs.

The Future of Industrial Construction: Metal Insulated Sandwich Panels Leading the Way

As the industrial sector continues to evolve, the demand for efficient, sustainable, and adaptable building solutions is only set to increase. Metal insulated sandwich panels are well-positioned to meet these growing needs, offering a blend of performance, aesthetics, and sustainability that is hard to match with traditional construction methods.

The ongoing advancements in panel technology promise even greater benefits in the future. Innovations in core materials, surface treatments, and manufacturing processes are likely to further enhance the panels' insulation properties, durability, and environmental friendliness. As building codes become more stringent and energy efficiency standards more demanding, metal insulated sandwich panels will likely play an increasingly crucial role in industrial construction.

The integration of smart technologies with these panels is another exciting frontier. Future iterations might include embedded sensors for monitoring structural integrity, temperature, and humidity, providing real-time data for optimal building management. This integration of construction materials with digital technologies could revolutionize how industrial buildings are operated and maintained.

Choosing the Right Metal Insulated Sandwich Panels for Your Industrial Project

Selecting the appropriate metal insulated sandwich panels for an industrial project requires careful consideration of various factors. The specific requirements of the project, including insulation needs, load-bearing capacity, fire resistance, and aesthetic preferences, should guide the selection process. It's crucial to work with reputable manufacturers who can provide detailed specifications and performance data for their products.

Quality control is paramount when it comes to these panels. Look for manufacturers who employ advanced production lines and rigorous quality control systems. This should include comprehensive inspections of steel coils, aluminum foil, and polyurethane components, as well as thorough testing of product thickness, paint film thickness, mechanical strength, flame retardancy, and overall appearance.

Conclusion

metal insulated sandwich panels have become indispensable in industrial construction due to their unparalleled combination of insulation efficiency, durability, safety, and versatility. As the industrial sector continues to prioritize energy efficiency, sustainability, and cost-effectiveness, these panels are set to play an even more significant role in shaping the future of industrial architecture.

For those looking to leverage the benefits of metal insulated sandwich panels in their next industrial project, reaching out to experts in the field is a wise first step. For more information on how these innovative panels can transform your industrial building project, feel free to contact us at info@sdqsc.com.