- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Eco-Friendly Thermal Insulation Wall Panels Are Trending in Construction?

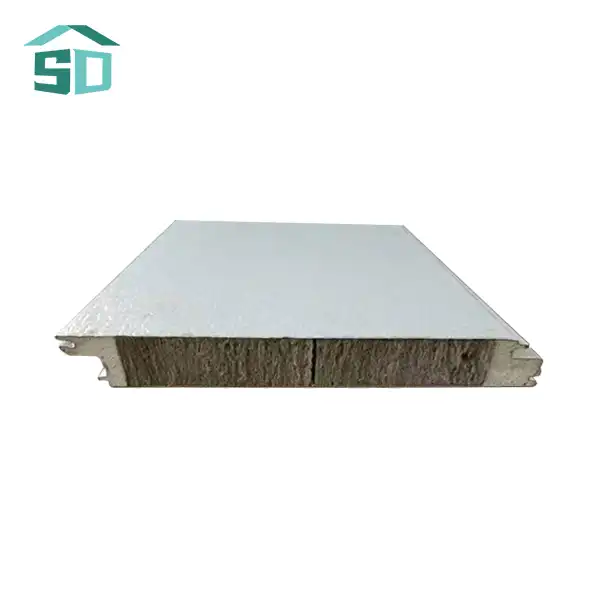

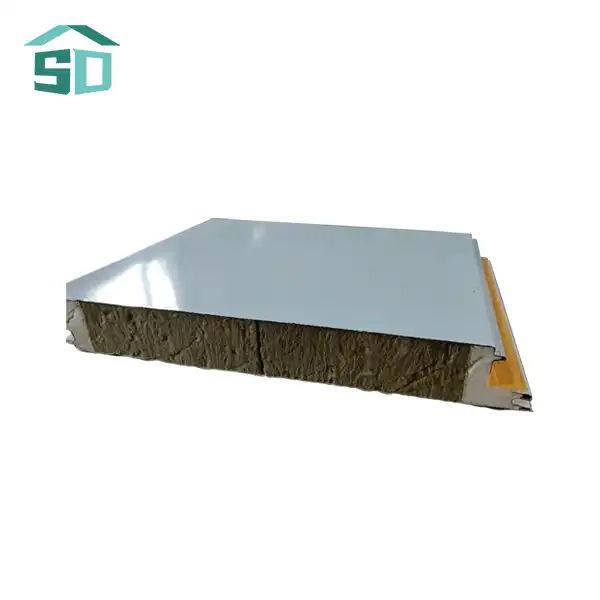

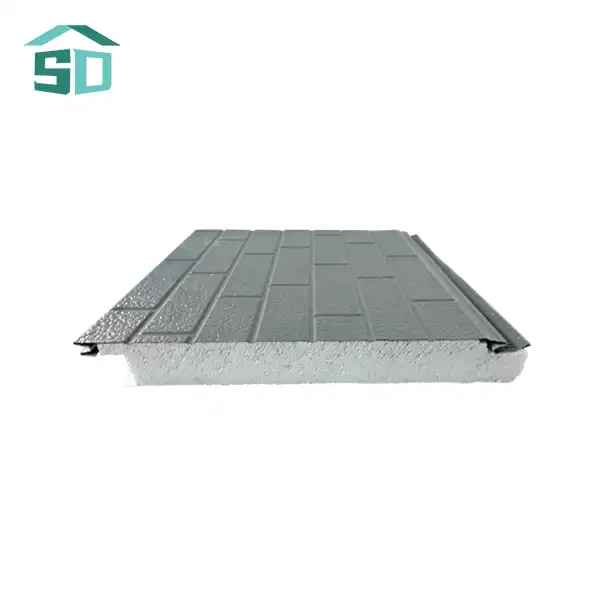

Eco-friendly thermal insulation wall panels are rapidly gaining traction in the construction industry due to their multifaceted benefits. These innovative panels offer superior energy efficiency, reducing heating and cooling costs while minimizing environmental impact. Their sustainable materials and manufacturing processes align with growing environmental consciousness. Additionally, these panels provide excellent thermal performance, fire resistance, and durability, making them a cost-effective long-term solution for modern buildings. As the construction sector increasingly prioritizes sustainability and energy conservation, eco-friendly thermal insulation wall panels have emerged as a cutting-edge solution that meets both environmental and performance demands.

The Environmental Impact of Eco-Friendly Thermal Insulation Wall Panels

Eco-friendly thermal insulation wall panels are revolutionizing the construction industry with their minimal environmental footprint. These panels are often manufactured using recycled or renewable materials, significantly reducing the demand for virgin resources. For instance, some manufacturers utilize recycled glass, plastic, or even agricultural byproducts in their production processes.

The environmental benefits extend beyond the manufacturing stage. Once installed, these panels dramatically improve a building's energy efficiency. By providing superior insulation, they reduce the need for heating and cooling, thereby lowering energy consumption and associated greenhouse gas emissions. This energy-saving capability is particularly crucial in the face of global climate change, as buildings account for a substantial portion of global energy use and carbon emissions.

Moreover, the longevity of eco-friendly thermal insulation wall panels contributes to their sustainability. Their durability means they need to be replaced less frequently, reducing waste and the need for new materials over time. Many of these panels are also designed to be recyclable at the end of their life cycle, further minimizing their environmental impact.

Sustainable Materials in Thermal Insulation Panels

The materials used in eco-friendly thermal insulation wall panels are at the heart of their environmental benefits. Manufacturers are increasingly turning to sustainable options such as:

- Recycled plastic: Transformed into effective insulation materials

- Sheep's wool: A natural, renewable insulator with excellent thermal properties

- Cellulose: Made from recycled paper products

- Cork: A naturally occurring, renewable bark that provides excellent insulation

- Recycled cotton: Often sourced from discarded denim

These materials not only provide excellent insulation but also significantly reduce the carbon footprint associated with panel production. The use of such sustainable materials aligns with the growing demand for environmentally responsible construction practices.

Energy Efficiency and Cost Savings with Thermal Insulation Wall Panels

Thermal insulation wall panels are engineered to maximize energy efficiency in buildings. Their primary function is to create a thermal barrier between the interior and exterior environments, effectively reducing heat transfer. This insulation capability translates into substantial energy savings for both heating and cooling systems.

The efficiency of these panels is often measured by their R-value, which indicates thermal resistance. Higher R-values signify better insulation properties. Eco-friendly thermal insulation wall panels typically boast high R-values, ensuring optimal thermal performance. This superior insulation can lead to energy savings of up to 40% in some buildings, depending on the climate and specific panel characteristics.

The cost savings associated with these energy-efficient panels are twofold. Firstly, there's a direct reduction in energy bills due to decreased heating and cooling requirements. Secondly, the improved energy efficiency can lead to smaller, less expensive HVAC systems, as the building's thermal load is significantly reduced. Over time, these savings can offset the initial investment in high-quality insulation panels.

Long-Term Economic Benefits

While the upfront costs of eco-friendly thermal insulation wall panels may be higher than traditional insulation methods, their long-term economic benefits are substantial. These benefits include:

- Reduced energy costs over the building's lifetime

- Increased property value due to improved energy efficiency

- Potential eligibility for green building certifications, which can lead to tax incentives or improved marketability

- Lower maintenance and replacement costs due to the panels' durability

Furthermore, as energy prices continue to rise, the cost savings associated with these efficient panels are likely to increase, making them an even more attractive investment for forward-thinking builders and property owners.

Innovative Features and Applications of Modern Thermal Insulation Panels

Modern thermal insulation wall panels are not just about energy efficiency; they come with a host of innovative features that enhance their functionality and appeal. These advancements have expanded the applications of thermal panels across various construction sectors.

One notable innovation is the development of phase-change materials (PCMs) integrated into insulation panels. These materials can absorb, store, and release large amounts of latent heat, providing additional thermal regulation. This technology allows the panels to actively manage temperature fluctuations, further improving energy efficiency and indoor comfort.

Another cutting-edge feature is the incorporation of vacuum insulation panels (VIPs) into thermal wall systems. VIPs offer exceptionally high thermal resistance in a thin profile, making them ideal for projects where space is at a premium. This technology allows for superior insulation performance without sacrificing valuable floor space.

Versatile Applications in Construction

The versatility of modern thermal insulation wall panels has led to their adoption in various construction applications:

- Residential buildings: Improving home energy efficiency and comfort

- Commercial structures: Enhancing thermal performance in offices, retail spaces, and warehouses

- Industrial facilities: Providing insulation for temperature-sensitive environments

- Retrofitting projects: Upgrading the energy efficiency of existing buildings

- Prefabricated construction: Integrating high-performance insulation into modular building elements

Additionally, these panels are being used in innovative ways beyond traditional wall applications. They're finding use in roofing systems, flooring, and even in specialized applications like refrigerated transport and aerospace technology.

Conclusion

Eco-friendly thermal insulation wall panels have emerged as a game-changing solution in the construction industry. Their ability to significantly enhance energy efficiency, reduce environmental impact, and provide long-term cost savings has made them increasingly popular among builders and property owners. The innovative features of these panels, coupled with their versatile applications, position them as a key component in the future of sustainable construction. As the industry continues to evolve towards more environmentally responsible practices, the adoption of eco-friendly thermal insulation wall panels is likely to accelerate, contributing to more energy-efficient and sustainable buildings worldwide.

At Weifang Sandong Building Materials Co., Ltd., we're at the forefront of this eco-friendly revolution. Our thermal insulation wall panels blend unparalleled insulation with fire safety, corrosion resistance, and customizable options. Whether you're embarking on a new construction project or upgrading an existing structure, our panels offer the perfect balance of efficiency and durability. Ready to elevate your building's performance? Contact us at info@sdqsc.com to discover how our thermal insulation solutions can transform your next project.

FAQ

What makes thermal insulation wall panels eco-friendly?

Eco-friendly thermal insulation wall panels often use recycled or sustainable materials, reduce energy consumption in buildings, and can be recycled at the end of their life cycle.

How do these panels contribute to energy efficiency?

They provide superior insulation, reducing heat transfer and minimizing the energy needed for heating and cooling.

Are eco-friendly thermal insulation panels more expensive?

While initial costs may be higher, they often result in significant long-term savings through reduced energy bills and maintenance costs.

Can these panels be used in all types of buildings?

Yes, they are versatile and can be used in residential, commercial, and industrial buildings, both in new construction and retrofitting projects.

How long do eco-friendly thermal insulation wall panels last?

With proper installation and maintenance, these panels can last for several decades, contributing to their cost-effectiveness and sustainability.

References

1. U.S. Department of Energy. (2022). Insulation. Energy.gov.

2. International Energy Agency. (2021). Buildings: A source of enormous untapped efficiency potential. IEA.

3. Green Building Council. (2023). LEED rating system. USGBC.

4. European Commission. (2022). Energy performance of buildings directive. EC.Europa.EU.

5. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2021). ASHRAE Handbook - Fundamentals. ASHRAE.