The Rise of Foam Exterior Wall Cladding in Modern Architecture

Understanding the Basics of Foam Cladding Systems

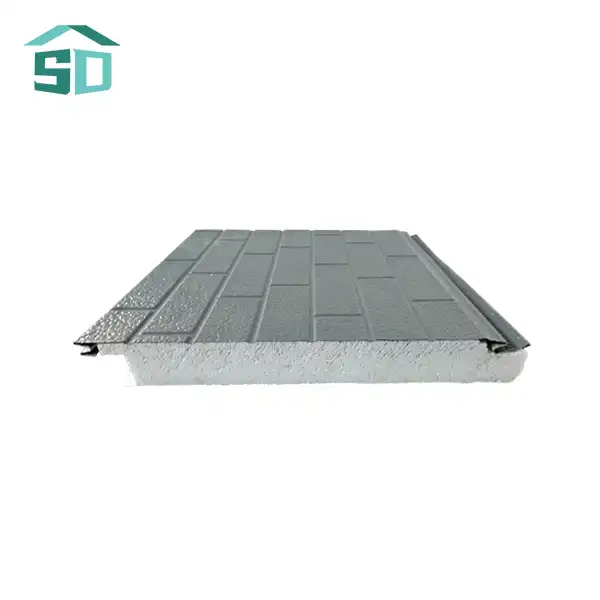

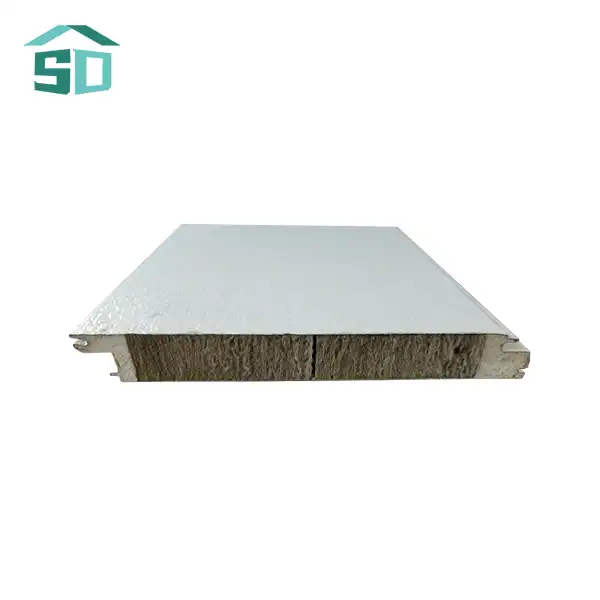

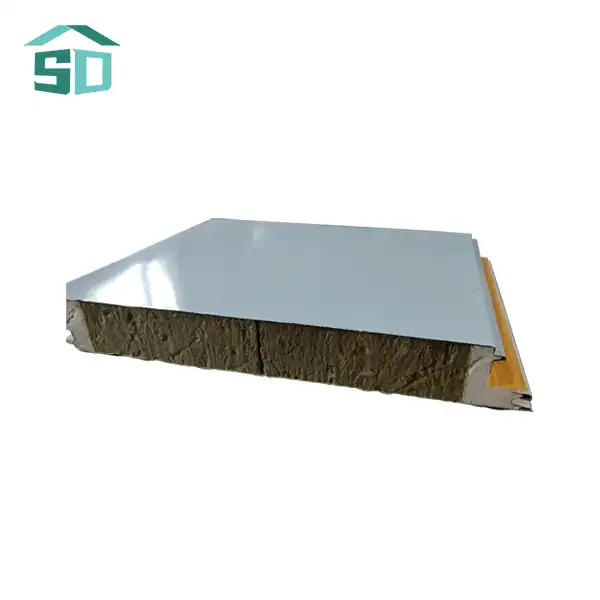

Foam exterior wall cladding is a cutting-edge building material that combines insulation and aesthetic appeal. Comprised of high-density polyurethane or polyisocyanurate foam, these panels are designed to provide superior thermal performance while offering a wide range of design possibilities. The core of foam exterior wall cladding is sandwiched between durable facing materials, typically made of aluminum or steel, enhancing its strength and weather resistance.

Key Advantages Driving Developer Preference

Developers are increasingly turning to foam exterior wall cladding for several compelling reasons. First and foremost is its exceptional insulation properties. With thermal conductivity as low as 0.018W/m.k, foam cladding significantly reduces heat transfer, leading to improved energy efficiency in buildings. This translates to lower heating and cooling costs, a major selling point for both residential and commercial properties.

Another crucial factor is the lightweight nature of foam cladding. Unlike traditional masonry or concrete facades, foam exterior wall cladding puts less stress on the building's structure, potentially reducing foundation requirements and overall construction costs. This lightweight characteristic also facilitates easier installation, reducing labor time and associated expenses.

Versatility in Design and Application

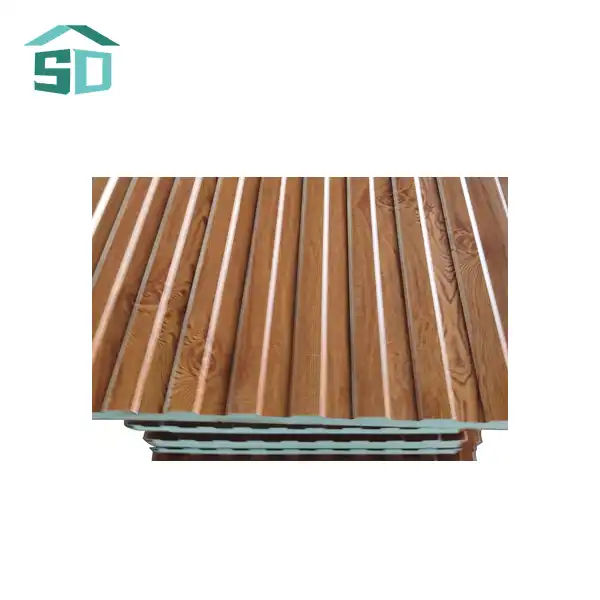

The aesthetic versatility of foam exterior wall cladding is a significant draw for architects and developers alike. Available in a wide array of colors, textures, and finishes, these panels can mimic the appearance of various materials, from sleek metal to rustic wood, without compromising on insulation performance. This flexibility allows for creative freedom in facade design, enabling developers to create visually striking buildings that stand out in urban landscapes.

Technical Aspects: Why Foam Cladding Outperforms Traditional Methods?

Superior Insulation and Energy Efficiency

The technical superiority of foam exterior wall cladding lies in its advanced insulation properties. With R-values significantly higher than traditional insulation materials, foam cladding creates a more effective thermal barrier. This enhanced insulation performance not only contributes to energy savings but also helps buildings meet and exceed increasingly stringent energy codes and sustainability standards.

Moreover, the seamless nature of foam cladding systems minimizes thermal bridges, those areas where heat can easily transfer through the building envelope. By reducing these weak points, foam exterior wall cladding ensures a more consistent and efficient insulation layer across the entire facade.

Moisture Management and Durability

One of the critical challenges in building envelope design is managing moisture. Foam exterior wall cladding excels in this area, offering excellent water-resistant properties with a waterproof rate as low as 0.0008. This high level of moisture resistance helps protect the building structure from water damage, mold growth, and other moisture-related issues, contributing to the longevity of the building.

Furthermore, the durability of foam cladding is a significant factor in its growing popularity among developers. Resistant to UV radiation, corrosion, and impact damage, foam exterior wall cladding maintains its performance and appearance over time, reducing maintenance costs and preserving the building's value.

Fire Safety and Regulatory Compliance

Safety is paramount in building design, and foam exterior wall cladding meets this challenge head-on. Many foam cladding products are manufactured to achieve a B1/B2 fire protection rating, meeting stringent safety standards. This fire-resistant quality is crucial for developers, as it helps ensure compliance with building codes and regulations while providing an additional layer of safety for occupants.

Economic and Environmental Considerations for Developers

Long-Term Cost Benefits of Foam Cladding

While the initial investment in foam exterior wall cladding may be higher than some traditional materials, developers recognize the long-term economic benefits. The energy savings achieved through superior insulation can result in significant reductions in operating costs over the building's lifespan. Additionally, the durability and low maintenance requirements of foam cladding translate to reduced repair and replacement expenses, further enhancing its cost-effectiveness.

Sustainability and Green Building Certifications

In an era of increasing environmental consciousness, foam exterior wall cladding aligns well with sustainable building practices. Many foam cladding products are manufactured using environmentally friendly processes and materials, contributing to a reduced carbon footprint. The energy efficiency provided by foam cladding also plays a crucial role in achieving green building certifications such as LEED (Leadership in Energy and Environmental Design), which can enhance a property's market value and appeal to environmentally conscious tenants or buyers.

Streamlining Construction Processes

The ease of installation associated with foam exterior wall cladding is a significant advantage for developers looking to optimize construction timelines. The lightweight nature of the panels, combined with their large size, allows for rapid installation, reducing on-site labor requirements and potentially shortening project durations. This efficiency can lead to earlier occupancy dates and faster returns on investment, a crucial consideration in the competitive real estate market.

Conclusion

Conclusion

Foam exterior wall cladding has emerged as a trusted solution for developers seeking to enhance building performance, aesthetics, and sustainability. Its superior insulation properties, design versatility, and long-term economic benefits make it an attractive option for a wide range of construction projects. As the construction industry continues to evolve, foam cladding stands out as a technology that meets the current demands for energy efficiency, durability, and design flexibility while positioning buildings for future challenges and opportunities.

Are you considering foam exterior wall cladding for your next project? Weifang Sandong Building Materials Co., Ltd. offers state-of-the-art foam cladding solutions tailored to your specific needs. Our products combine exceptional insulation performance with aesthetic versatility, ensuring your building stands out both in efficiency and design. Contact us at info@sdqsc.com to learn how our foam exterior wall cladding can elevate your construction project to new heights of performance and beauty.

FAQ

What is the typical lifespan of foam exterior wall cladding?

With proper installation and maintenance, foam exterior wall cladding can last 30-50 years, depending on environmental conditions and the specific product used.

Can foam cladding be used in retrofit projects?

Yes, foam exterior wall cladding is an excellent option for building retrofits, offering improved insulation and aesthetics without requiring extensive structural modifications.

How does foam cladding compare to traditional insulation methods in terms of thickness?

Foam cladding typically provides superior insulation with less thickness compared to traditional methods, allowing for more usable interior space in buildings.

References

1.Building Science Corporation. (2021). "Guide to Insulating Sheathing."

2.U.S. Department of Energy. (2022). "Insulation Materials."

3.National Institute of Building Sciences. (2020). "Whole Building Design Guide: Building Envelope Design Guide - Wall Systems."

4.American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2021). "ASHRAE Handbook - Fundamentals." Atlanta, GA: ASHRAE.

5.International Code Council. (2021). "International Energy Conservation Code." Washington, DC: ICC.