The Unmatched Benefits of Fireproof Insulation Panels in Industrial Settings

Enhanced Fire Safety and Risk Mitigation

Fireproof insulation panels are engineered to withstand extreme temperatures, providing a robust defense against fire hazards in industrial environments. These panels are constructed with non-combustible materials and fire-rated cores, significantly reducing the risk of fire spread and structural damage. The advanced composition of fireproof panels helps contain flames, minimizing the potential for catastrophic loss in the event of a fire outbreak.

Moreover, these panels play a crucial role in smoke and toxic gas mitigation. During a fire, the non-combustible nature of fireproof insulation panels helps limit the generation and spread of harmful emissions, thereby enhancing personnel safety and reducing environmental impact. This feature is particularly valuable in industries dealing with flammable materials or high-temperature processes.

Superior Thermal Performance and Energy Efficiency

Fireproof insulation panels boast exceptional thermal insulation properties, making them an ideal choice for industrial applications where temperature control is critical. The high-performance insulation core of these panels effectively maintains stable indoor temperatures, reducing the load on heating and cooling systems. This translates to significant energy savings and lower operational costs for industrial facilities.

The thermal efficiency of fireproof insulation panels also contributes to improved working conditions for employees. By maintaining consistent temperatures throughout the facility, these panels help create a more comfortable and productive work environment. Additionally, the superior insulation properties protect sensitive equipment and stored goods from temperature fluctuations, ensuring optimal performance and product integrity.

Durability and Long-Term Cost-Effectiveness

Fireproof insulation panels are built to last, offering exceptional durability even in harsh industrial environments. These panels are resistant to corrosion, moisture, and UV radiation, ensuring their longevity and performance over time. The robust construction of fireproof panels helps maintain structural integrity, reducing the need for frequent repairs or replacements.

The long-term cost-effectiveness of fireproof insulation panels is a significant advantage for industrial applications. While the initial investment may be higher compared to traditional building materials, the durability, energy efficiency, and fire protection benefits lead to substantial savings over the lifespan of the structure. Furthermore, the low maintenance requirements of these panels contribute to reduced operational costs and minimal downtime for industrial facilities.

Versatility and Customization Options for Industrial Applications

Adaptability to Various Industrial Structures

Fireproof insulation panels offer remarkable versatility, making them suitable for a wide range of industrial structures. These panels can be used in the construction of warehouses, manufacturing plants, cold storage facilities, and processing units. The adaptability of fireproof panels allows for seamless integration with existing structures during renovations or expansions, providing a cost-effective solution for upgrading industrial facilities.

The panels' lightweight nature facilitates easier installation and reduces the load on the building's structural framework. This characteristic is particularly beneficial in retrofit projects where minimizing additional stress on existing structures is crucial. The versatility of fireproof insulation panels extends to their application in both exterior and interior walls, roofs, and partitions, offering comprehensive protection and insulation throughout the industrial facility.

Customization Options for Specific Industrial Needs

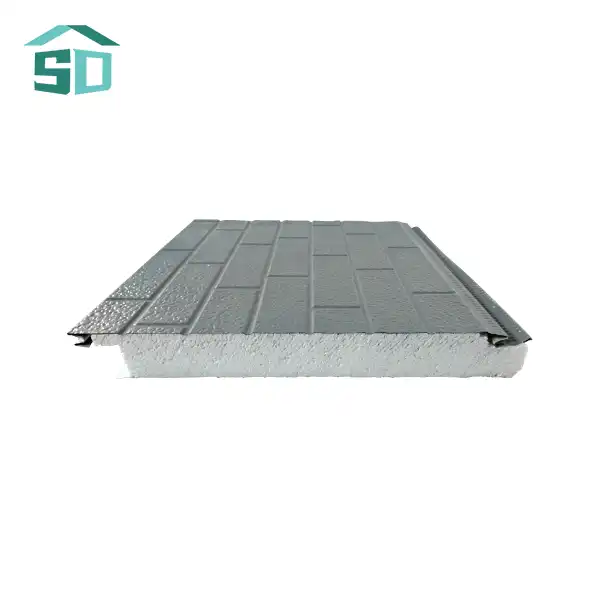

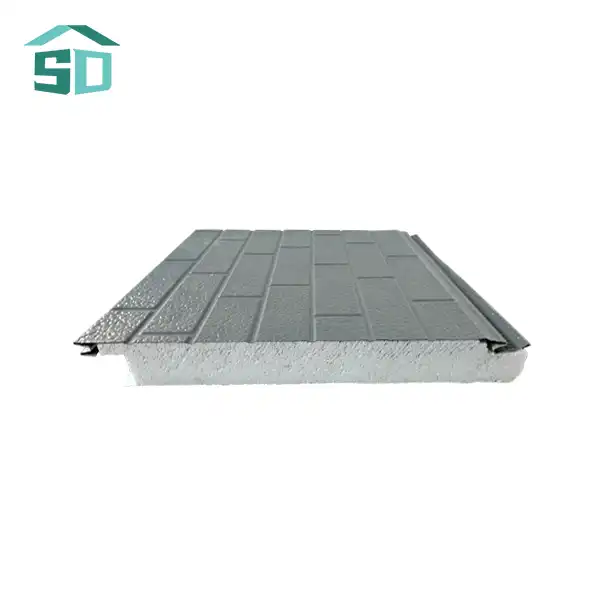

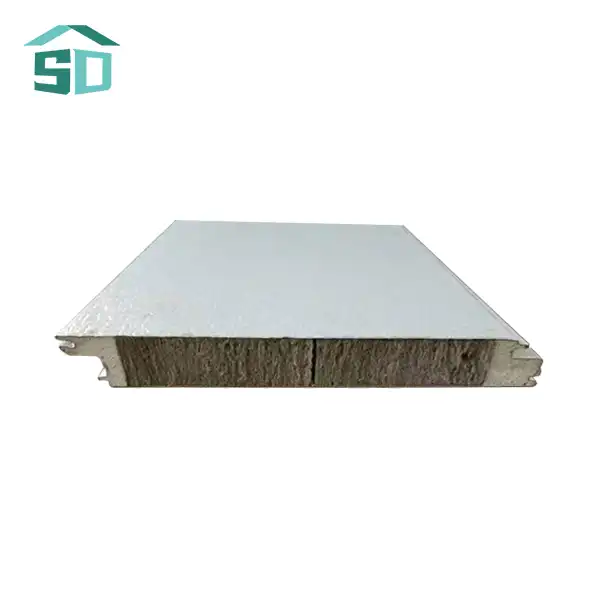

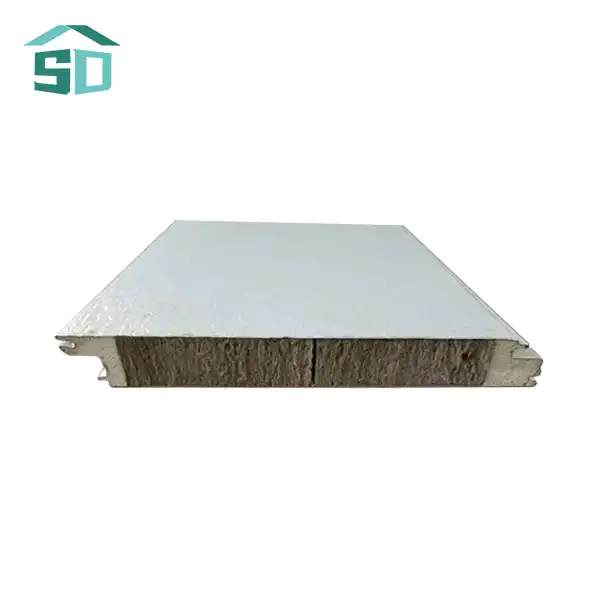

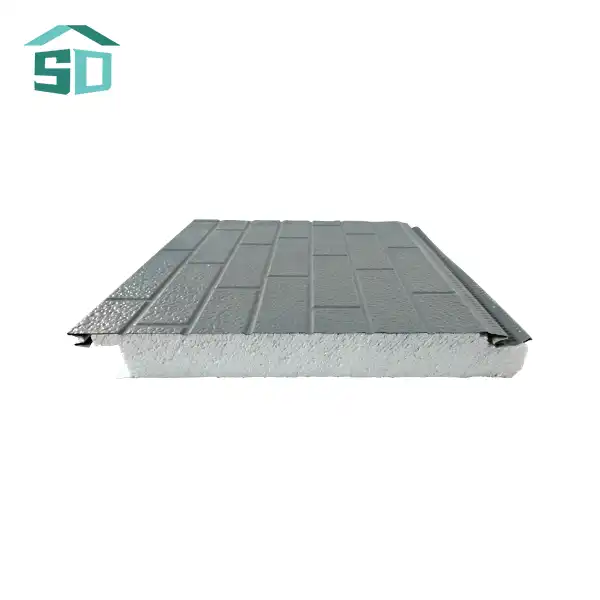

Fireproof insulation panels can be customized to meet the specific requirements of different industrial applications. Manufacturers offer a range of panel thicknesses, typically from 50mm to 100mm, allowing businesses to select the optimal insulation level for their needs. The panels are available in various materials, including aluminum, steel, and stainless steel, catering to different durability and aesthetic preferences.

The insulation core of these panels can also be tailored to specific industrial requirements. Options such as polyurethane, polystyrene, rock wool, and glass wool provide varying degrees of fire resistance and thermal insulation. This customization extends to surface treatments, with coating, painting, and anodizing options available to enhance the panels' resistance to chemical exposure or harsh environmental conditions common in industrial settings.

Aesthetic Considerations in Industrial Design

While functionality is paramount in industrial applications, the aesthetic appeal of fireproof insulation panels should not be overlooked. These panels offer a clean, modern appearance that can significantly enhance the visual appeal of industrial facilities. The availability of custom color matching allows businesses to align the panels with their corporate branding or specific design requirements.

The sleek profile of fireproof insulation panels contributes to a professional and well-maintained appearance, which can be particularly important for industries that regularly host client visits or prioritize their public image. The panels' smooth surfaces are also easier to clean and maintain, helping industrial facilities maintain a hygienic and presentable environment with minimal effort.

Installation and Maintenance Considerations for Industrial Settings

Streamlined Installation Process

The installation of fireproof insulation panels in industrial settings is a relatively straightforward process, offering significant time and cost savings compared to traditional construction methods. The panels are designed for easy handling and rapid assembly, reducing on-site construction time and minimizing disruptions to ongoing operations. This efficiency is particularly valuable in industrial environments where downtime can result in substantial financial losses.

The installation process typically involves preparing the surface, cutting panels to size if necessary, and securing them to the structure using appropriate fasteners. Specialized sealants are then applied to edges and joints to enhance insulation performance and ensure airtight installation. The simplicity of this process allows for quicker project completion and earlier occupancy of industrial spaces.

Minimal Maintenance Requirements

Fireproof insulation panels are engineered for longevity and low maintenance, making them ideal for industrial applications where operational efficiency is crucial. The panels' resistance to moisture, UV radiation, and corrosion significantly reduces the need for regular upkeep. This low-maintenance characteristic translates to reduced long-term costs and minimal disruptions to industrial operations.

Routine maintenance of fireproof insulation panels typically involves simple cleaning to maintain their appearance and integrity. The smooth, non-porous surfaces of these panels resist the accumulation of dirt and contaminants, making them easy to clean with standard industrial cleaning methods. Regular inspections can help identify and address any potential issues early, ensuring the continued performance and longevity of the panels.

Integration with Industrial Fire Safety Systems

Fireproof insulation panels can be seamlessly integrated with other fire safety systems commonly used in industrial settings. The panels' design allows for easy incorporation of fire detection and suppression systems, such as sprinklers and smoke detectors. This integration enhances the overall fire safety strategy of the industrial facility, providing a comprehensive approach to risk mitigation.

When planning the installation of fireproof insulation panels, it's essential to consider their compatibility with existing or planned fire safety infrastructure. Proper coordination between panel installation and the integration of fire safety systems ensures optimal performance and compliance with industrial safety standards. This holistic approach to fire safety can contribute to reduced insurance premiums and improved regulatory compliance for industrial businesses.

Conclusion

Fireproof insulation panels offer a compelling solution for industrial applications, combining unparalleled fire safety with superior thermal performance and durability. Their versatility, customization options, and ease of installation make them an ideal choice for a wide range of industrial structures. By investing in fireproof insulation panels, businesses can enhance the safety of their facilities, improve energy efficiency, and ensure long-term cost-effectiveness.

As industrial safety standards continue to evolve, the adoption of advanced materials like fireproof insulation panels becomes increasingly crucial. These panels not only meet current regulatory requirements but also future-proof industrial facilities against potential changes in building codes and safety regulations.

For more information on how fireproof insulation panels can benefit your industrial project, or to discuss customized solutions for your specific needs, please contact us at info@sdqsc.com. Our team of experts is ready to assist you in enhancing the safety, efficiency, and sustainability of your industrial facility.

References

1.National Fire Protection Association. (2021). NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components.

2.International Code Council. (2021). International Building Code (IBC).

3.U.S. Department of Energy. (2022). Energy Efficiency in Industrial Facilities.

4.European Committee for Standardization. (2019). EN 13501-1: Fire classification of construction products and building elements.

5.Underwriters Laboratories. (2022). UL 263: Fire Tests of Building Construction and Materials.