Unparalleled Performance: The Core Advantages of PU Sandwich Panels

Exceptional Thermal Insulation Properties

One of the primary reasons PU sandwich panels are widely used is their outstanding thermal insulation capabilities. The polyurethane core acts as a highly effective barrier against heat transfer, significantly reducing energy consumption for heating and cooling. This thermal efficiency translates to lower utility costs and improved environmental sustainability for buildings. In fact, PU sandwich panels can achieve R-values (a measure of thermal resistance) that are up to 70% higher than traditional insulation materials of the same thickness.

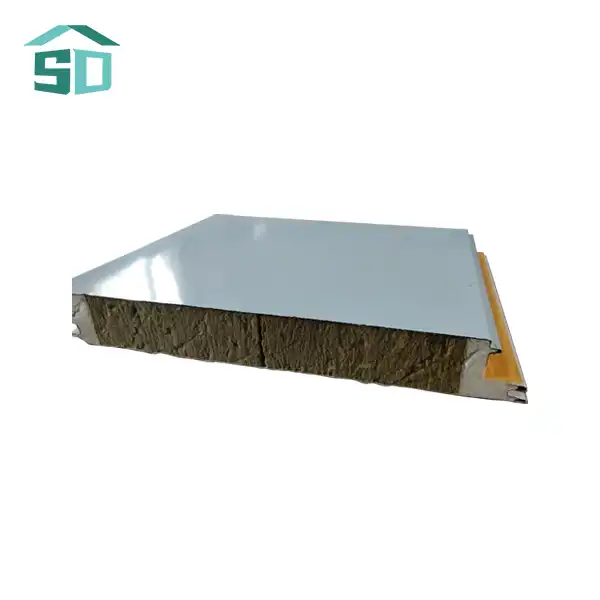

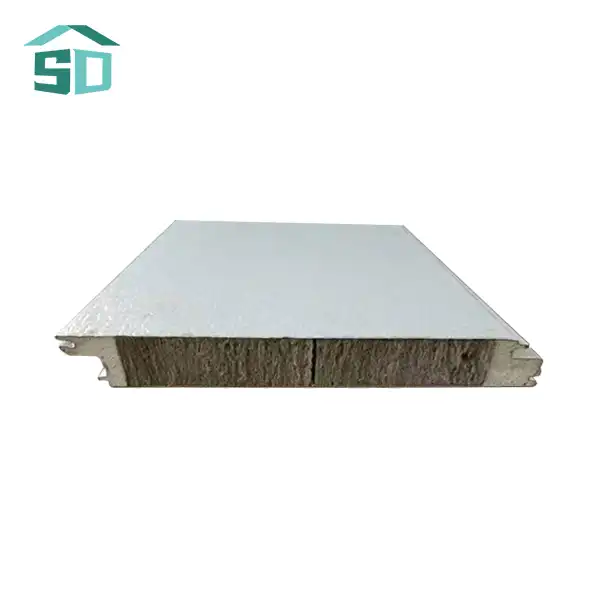

Structural Integrity and Durability

PU sandwich panels boast remarkable strength-to-weight ratios, making them an ideal choice for both load-bearing and non-load-bearing applications. The rigid polyurethane core, bonded to metal facings, creates a composite structure that resists bending, twisting, and warping. This inherent stability ensures that buildings maintain their structural integrity over time, even when exposed to harsh environmental conditions. The durability of PU sandwich panels contributes to longer building lifespans and reduced maintenance costs, making them a cost-effective solution in the long run.

Fire Resistance and Safety

Safety is paramount in construction, and PU sandwich panels address this concern with their fire-resistant properties. Modern PU formulations incorporate flame retardants that significantly reduce fire spread and smoke generation. Many PU sandwich panels meet or exceed stringent fire safety standards, providing crucial time for evacuation in the event of a fire. This fire resistance is particularly valuable in industrial and commercial settings where fire hazards are a significant concern.

Versatility and Adaptability: PU Sandwich Panels in Various Applications

Industrial and Commercial Buildings

The robust nature of PU sandwich panels makes them ideal for industrial and commercial constructions. Warehouses, factories, and large-scale retail spaces benefit from the panels' ability to create expansive, uninterrupted surfaces quickly and efficiently. The panels' resistance to chemicals, moisture, and temperature fluctuations ensures they maintain their integrity in challenging industrial environments. Additionally, the ease of installation and potential for prefabrication significantly reduce construction time and labor costs, making PU sandwich panels a preferred choice for large-scale projects.

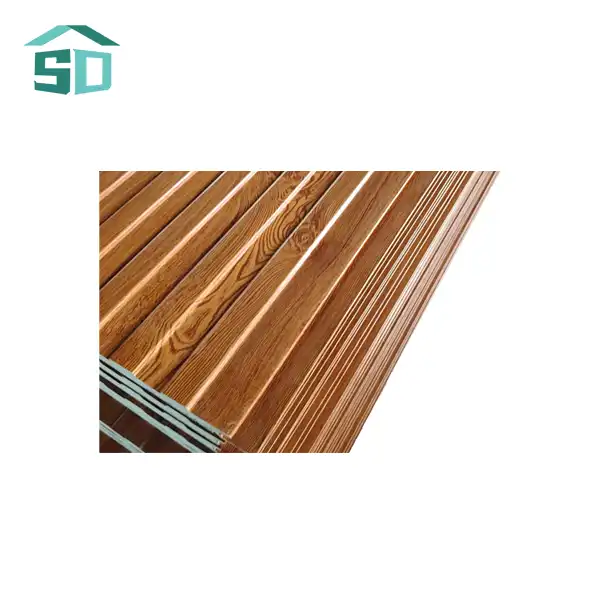

Residential Construction

In the residential sector, PU sandwich panels are gaining traction for their ability to create energy-efficient, comfortable living spaces. Homeowners appreciate the superior insulation properties that keep interiors warm in winter and cool in summer, leading to substantial energy savings. The panels' versatility allows for creative architectural designs, from modern minimalist homes to traditional styles. Moreover, the sound-dampening qualities of PU sandwich panels contribute to a quieter, more peaceful living environment, especially in urban areas or multi-family dwellings.

Cold Storage and Controlled Environments

PU sandwich panels excel in applications requiring strict temperature control, such as cold storage facilities, food processing plants, and pharmaceutical storage areas. The exceptional insulation properties of the polyurethane core help maintain consistent temperatures while minimizing energy consumption. The panels' smooth, seamless surfaces are easy to clean and maintain, meeting stringent hygiene standards in these sensitive environments. Furthermore, the panels' resistance to moisture and vapor transmission prevents condensation issues that can compromise product integrity in cold storage settings.

Sustainability and Future Trends: PU Sandwich Panels in Green Building

Environmental Impact and Energy Efficiency

As the construction industry shifts towards more sustainable practices, PU sandwich panels are playing a crucial role in green building initiatives. The energy efficiency provided by these panels significantly reduces a building's carbon footprint over its lifetime. Modern manufacturing processes for PU sandwich panels are becoming increasingly environmentally friendly, with many manufacturers focusing on reducing waste and using recycled materials where possible. The long lifespan and recyclability of PU sandwich panels also contribute to their overall sustainability, aligning with circular economy principles.

Innovations in PU Sandwich Panel Technology

The future of PU sandwich panels looks promising, with ongoing research and development focused on enhancing their performance and sustainability. Innovations in bio-based polyurethane formulations are reducing the reliance on petroleum-based products, further improving the panels' environmental credentials. Advanced manufacturing techniques are exploring ways to incorporate smart technologies into PU sandwich panels, such as integrated sensors for monitoring structural health or energy performance. These developments are set to expand the applications and benefits of PU sandwich panels in the coming years.

Integration with Modern Construction Techniques

PU sandwich panels are increasingly being integrated with cutting-edge construction methodologies, such as modular and off-site construction. Their lightweight nature and ease of customization make them ideal for prefabricated building elements, allowing for faster, more efficient construction processes. This synergy between PU sandwich panels and modern construction techniques is driving the adoption of these panels in a wider range of projects, from rapid disaster relief housing to high-end, sustainable architectural designs.

Conclusion

PU sandwich panels have revolutionized the construction industry with their unique combination of performance, versatility, and sustainability. From their superior insulation properties to their structural integrity and fire resistance, these panels offer solutions to many challenges faced in modern building design and construction. As the industry continues to evolve towards more sustainable and efficient practices, PU sandwich panels are poised to play an even more significant role in shaping the built environment of the future.

For those seeking to leverage the benefits of PU sandwich panels in their projects, Weifang Sandong Building Materials Co., Ltd. offers a comprehensive range of high-quality solutions. To explore how PU sandwich panels can enhance your next construction project, contact us at info@sdqsc.com for expert advice and personalized service.