Applications of Insulated Sandwich Wall Panels in Various Industries

Commercial and Industrial Buildings

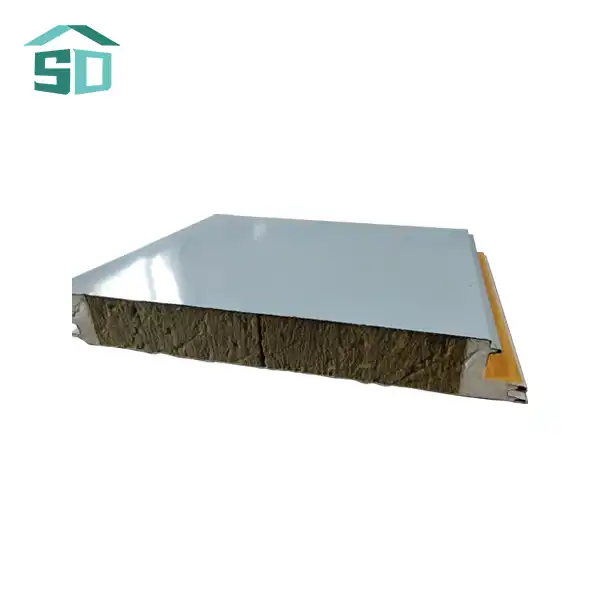

Insulated sandwich wall panels have revolutionized the construction of commercial and industrial buildings. These panels are particularly well-suited for warehouses, manufacturing facilities, and distribution centers. The superior insulation properties of these panels help maintain consistent temperatures inside the building, which is crucial for storing goods and creating comfortable working environments. Moreover, their fire-resistant qualities (with a fire-protection rating of B1/B2) enhance the safety of these structures, making them an excellent choice for industrial applications where fire hazards are a concern.

Retail spaces and office buildings also benefit from the use of insulated sandwich wall panels. The panels' customizable colors and patterns allow architects to create visually appealing exteriors that align with brand aesthetics. With a thermal conductivity of 0.018W/m.k and thermal resistance of 2.09m2k/w, these panels significantly reduce energy costs associated with heating and cooling, making them an attractive option for environmentally conscious businesses.

Residential Construction

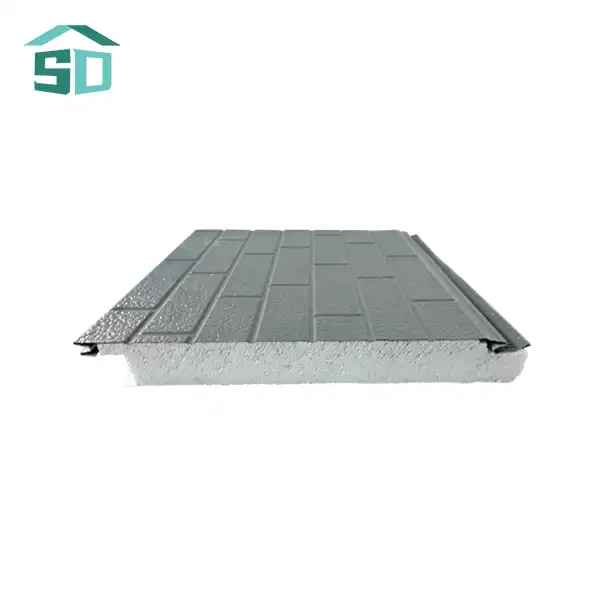

In the residential sector, insulated sandwich wall panels are gaining popularity for both new constructions and renovations. These panels are ideal for creating energy-efficient homes that maintain comfortable indoor temperatures year-round. The panels' excellent insulation properties contribute to reduced heating and cooling costs, making them an economical choice for homeowners in the long run.

Insulated sandwich wall panels are particularly beneficial in areas with extreme weather conditions. Their high wind resistance (up to 8.0 Kpa) makes them suitable for coastal regions prone to strong winds. The panels' waterproof rate of 0.0008 also provides excellent protection against moisture intrusion, preventing issues like mold growth and structural damage.

For homeowners looking to expand their living space quickly, these panels offer a rapid construction solution. The easy-to-install nature of insulated sandwich panels allows for faster project completion compared to traditional building methods, minimizing disruption to daily life.

Specialized Uses of Insulated Sandwich Wall Panels

Cold Storage and Food Processing Facilities

One of the most critical applications of insulated sandwich wall panels is in cold storage and food processing facilities. These environments require strict temperature control to maintain food safety and quality. The exceptional insulation properties of these panels, with a thermal conductivity of 0.018W/m.k, ensure that cold temperatures are maintained efficiently, reducing energy consumption and operational costs.

The panels' smooth, non-porous surfaces also contribute to hygiene in food processing areas. They are easy to clean and resistant to bacterial growth, meeting the stringent sanitation requirements of the food industry. Additionally, the panels' corrosion-proof design ensures durability in the often humid conditions of cold storage facilities.

Agricultural Buildings

In the agricultural sector, insulated sandwich wall panels are used extensively for constructing barns, storage facilities, and livestock housing. These panels help maintain optimal temperatures for animal welfare and crop storage. The panels' resistance to moisture and ease of cleaning make them ideal for agricultural environments where hygiene is paramount.

The durability of insulated sandwich wall panels, with a compressive strength of 52.7kpa, allows them to withstand the rigors of agricultural use, including potential impacts from machinery or livestock. Their fire-resistant properties also enhance the safety of agricultural buildings, protecting valuable livestock and produce.

Modular and Portable Buildings

The lightweight nature and ease of installation of insulated sandwich wall panels make them perfect for modular and portable buildings. These structures are increasingly used for temporary offices, emergency housing, and remote work sites. The panels' customizable dimensions (with exterior widths of 383mm and interior widths of 450mm) allow for flexible design options, catering to various spatial requirements.

In disaster relief situations, the rapid assembly of structures using these panels can provide quick, safe, and comfortable shelter. The panels' thermal insulation properties ensure that these temporary structures can maintain comfortable living conditions in diverse climates.

Innovative Applications and Future Trends

Green Building and Sustainable Architecture

As the construction industry moves towards more sustainable practices, insulated sandwich wall panels are playing a crucial role in green building design. These panels contribute to energy efficiency, reducing the carbon footprint of buildings. Their long lifespan and recyclable components align with the principles of sustainable construction.

Architects are increasingly incorporating these panels into designs that prioritize environmental sustainability. The panels' ability to contribute to LEED certification makes them attractive for projects aiming to meet green building standards. As environmental regulations become stricter, the demand for such energy-efficient building materials is expected to grow.

Integration with Smart Building Technologies

The future of insulated sandwich wall panels lies in their integration with smart building technologies. Manufacturers are exploring ways to incorporate sensors and smart materials into these panels, allowing for real-time monitoring of building performance. This integration could enable automatic adjustments to HVAC systems based on the panels' thermal performance, further enhancing energy efficiency.

Additionally, research is being conducted on incorporating phase-change materials into insulated sandwich panels. These materials could absorb excess heat during the day and release it at night, providing an even more stable indoor temperature without relying solely on mechanical heating and cooling systems.

Aesthetic Innovations

While insulated sandwich wall panels are known for their functional benefits, there's a growing focus on their aesthetic potential. Manufacturers are developing panels with more diverse finishes, textures, and patterns, allowing architects to create visually striking facades. This trend is particularly evident in the use of these panels in modern architectural designs, where they serve both functional and aesthetic purposes.

The development of printable surfaces on these panels opens up new possibilities for customization. Buildings can now feature unique designs, artwork, or branding directly on their exterior panels, blending functionality with visual appeal.

Conclusion

Insulated sandwich wall panels have proven to be a versatile and efficient building material, finding applications across various sectors of the construction industry. Their combination of thermal efficiency, durability, and adaptability makes them an excellent choice for a wide range of building projects. As technology advances and sustainability becomes increasingly important, these panels are likely to play an even more significant role in shaping the future of construction. For more information on how insulated sandwich wall panels can benefit your next project, please contact us at info@sdqsc.com.