The Anatomy of Metal Insulated Sandwich Panels

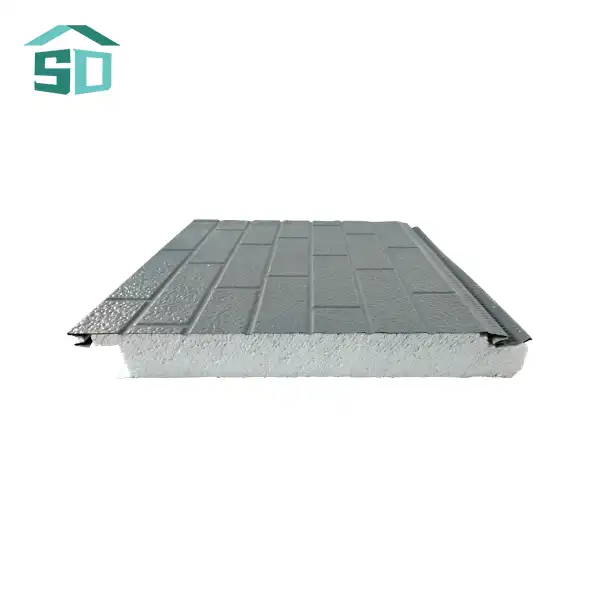

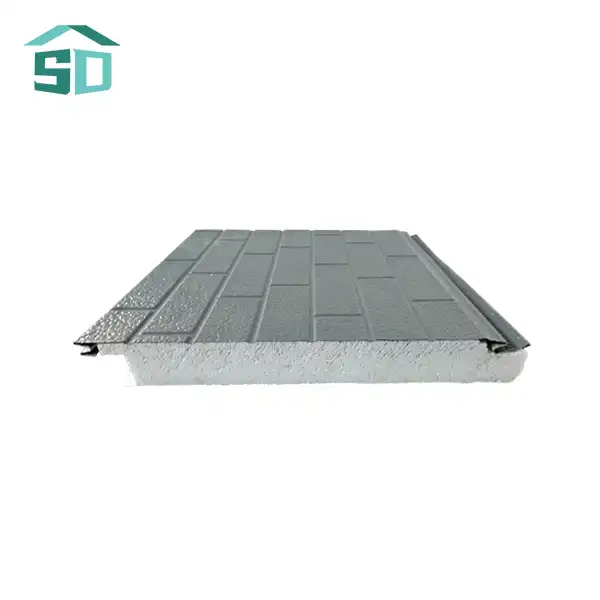

Outer Metal Facings: Strength and Aesthetics Combined

The exterior layers of metal insulated sandwich panels play a crucial role in their overall performance and appearance. Typically constructed from steel or aluminum, these facings provide durability, weather resistance, and structural integrity. The thickness of these surface materials can vary, usually ranging from 0.23mm to 0.27mm, depending on the specific requirements of the project.

One of the standout features of these metal facings is their customizable aesthetics. Architects and builders can choose from a wide range of colors and patterns, allowing for creative freedom in design while maintaining the panel's functional properties. This versatility makes metal insulated sandwich panels an attractive option for both interior and exterior wall finishes, seamlessly blending form with function.

The Core: PU/PIR Insulation

At the heart of metal insulated sandwich panels lies the insulation core, typically composed of polyurethane (PU) or polyisocyanurate (PIR) foam. These advanced insulation materials are renowned for their exceptional thermal performance, contributing significantly to the panel's overall efficiency.

The PU/PIR core boasts an impressively low thermal conductivity of 0.018 W/m.K, which translates to superior insulation capabilities. This property enables the panels to maintain ideal temperatures within buildings, reducing energy consumption for heating and cooling. The thermal resistance of these panels, measured at 2.09 m²K/W, further underscores their effectiveness in minimizing heat transfer.

Beyond thermal insulation, the PU/PIR core also contributes to the panel's structural integrity. With a compressive strength of 52.7 kPa, these panels can withstand significant loads, making them suitable for a variety of construction applications.

Key Benefits of Metal Insulated Sandwich Panels

Unparalleled Durability and Weather Resistance

Metal insulated sandwich panels are engineered to withstand the test of time and nature. Their metal construction ensures longevity and strength, while the corrosion-proof design protects against rust and weathering. This resilience is particularly evident in the panel's impressive wind resistance of 8.0 kPa, making them suitable for use in areas prone to high winds or severe weather conditions.

Moreover, these panels exhibit exceptional waterproof properties, with a waterproof rate of 0.0008. This feature is crucial in preventing moisture ingress, which could otherwise compromise the insulation performance and structural integrity of the building envelope.

Fire Safety and Regulatory Compliance

Safety is paramount in construction, and metal insulated sandwich panels address this concern effectively. These panels are fire safety certified, with fire-protection ratings of B1/B2. This certification ensures that the panels meet stringent fire safety standards, providing peace of mind to building owners and occupants alike.

The non-combustible nature of these panels makes them an ideal choice for creating safe environments in various building types, from residential complexes to industrial facilities. This feature not only enhances the overall safety of the structure but also aids in compliance with building regulations and insurance requirements.

Versatility in Application

One of the most compelling advantages of metal insulated sandwich panels is their versatility. These panels are suitable for both interior and exterior wall finishes, adapting to diverse architectural needs. Their application spans a wide range of projects, including:

- Residential complexes

- Office buildings

- Villas and luxury homes

- Garden structures

- Historic building renovations

- Municipal buildings

- Security kiosks

This adaptability is further enhanced by the panels' customizable dimensions. With the ability to tailor the length to specific project requirements and offering various thickness options (10mm for interior applications, 16mm/20mm for exterior use), these panels provide flexibility in design and installation.

Sustainability and Cost-Effectiveness

Eco-Friendly Insulation Solutions

As the construction industry increasingly focuses on sustainability, metal insulated sandwich panels emerge as an eco-friendly option. The use of sustainable materials in their production, combined with their energy-efficient properties, contributes to reducing the overall environmental impact of buildings.

The exceptional insulation properties of these panels lead to significant energy savings over the lifetime of a building. By maintaining stable indoor temperatures and reducing the load on HVAC systems, metal insulated sandwich panels help decrease energy consumption and, consequently, carbon emissions associated with building operations.

Long-Term Cost Benefits

While the initial investment in metal insulated sandwich panels may be higher compared to some traditional insulation methods, their long-term cost benefits are substantial. The durability and longevity of these panels translate to reduced maintenance and replacement costs over time.

Furthermore, the energy savings achieved through improved insulation can lead to significant reductions in utility bills. This combination of durability, energy efficiency, and low maintenance makes metal insulated sandwich panels a cost-effective choice for building owners and developers looking to optimize their investment in the long run.

Quality Assurance and Performance

The production of metal insulated sandwich panels involves rigorous quality control measures. Advanced production lines and comprehensive testing procedures ensure that each panel meets the highest standards of quality and performance. From the selection of raw materials to the final product, every stage is carefully monitored and tested.

Quality control measures include:

- Strict testing of steel coils and aluminum foil

- Comprehensive inspections of polyurethane properties

- Verification of product thickness and paint film thickness

- Assessment of mechanical strength and flame retardancy

- Thorough examination of product appearance

These stringent quality assurance processes ensure that architects, builders, and end-users can rely on the consistent performance and durability of metal insulated sandwich panels in their projects.

Conclusion

Metal insulated sandwich panels represent a cutting-edge solution in building insulation technology. By combining the strength and aesthetics of metal facings with the superior insulation properties of PU/PIR cores, these panels offer a comprehensive package of benefits. From energy efficiency and durability to fire safety and design flexibility, they address many of the key challenges faced in modern construction.

As the construction industry continues to evolve, with an increasing emphasis on sustainability, energy efficiency, and long-term cost-effectiveness, metal insulated sandwich panels are poised to play an even more significant role in shaping the buildings of the future. Their versatility, performance, and eco-friendly attributes make them an attractive option for a wide range of construction projects, from residential to commercial and industrial applications.

For those seeking to leverage the benefits of metal insulated sandwich panels in their construction projects, it's crucial to partner with experienced manufacturers who prioritize quality and innovation. If you're interested in exploring how these advanced insulation solutions can benefit your next project, we invite you to reach out to our team of experts at Weifang Sandong Building Materials Co., Ltd. Contact us at info@sdqsc.com for more information on our range of exterior cladding and facade solutions, including our high-performance metal insulated sandwich panels.